An automatic needle pressing machine for assembling the grounding pole core needle of a triangular plug

A grounding electrode and core needle technology, which is applied in the field of automatic needle pressing machines for triangular plug grounding core needle assembly, can solve the problems of large labor cost input, complex mold structure, disparity in assembly effect, etc., so as to overcome the large labor input and save money Consistent effect of manual and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

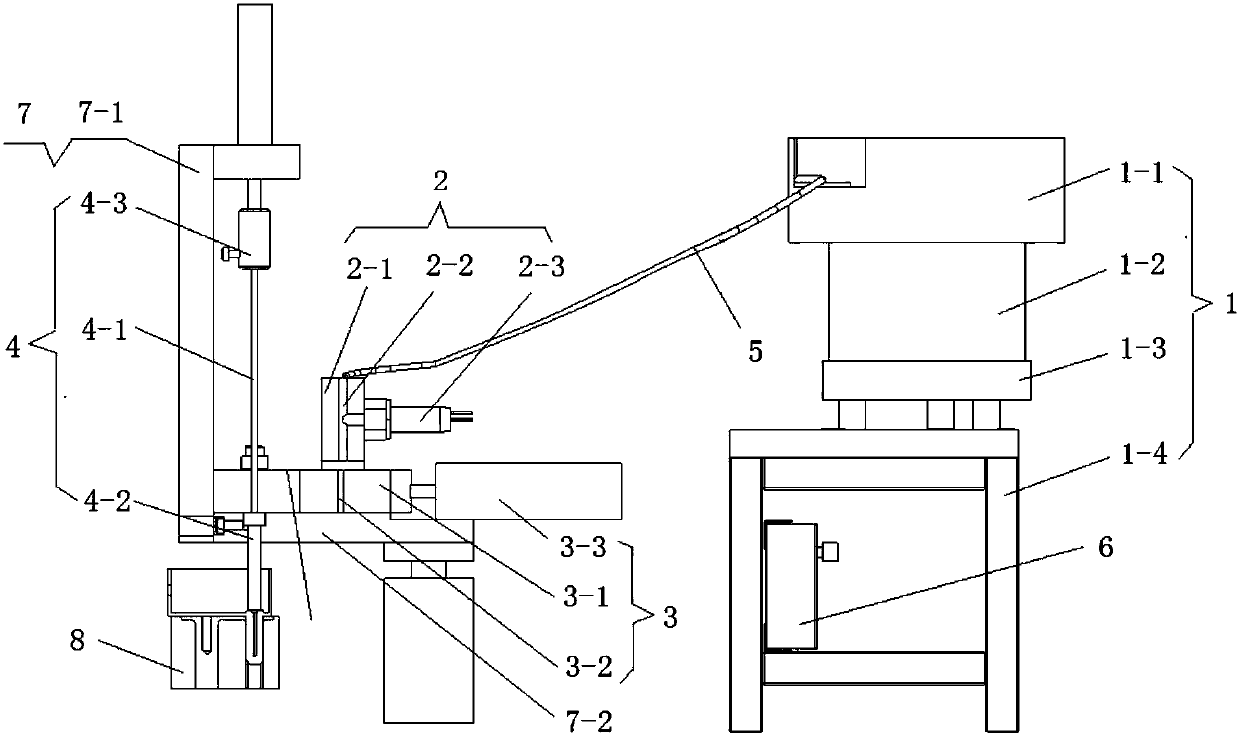

[0035] Such as figure 1 As shown in the figure, an automatic needle press machine for assembling the ground pole core pin of a triangular plug, including: a needle feeding mechanism 1, a needle dropping mechanism 2, a needle pushing mechanism 3, a needle pressing mechanism 4, a needle feeding guide rail 5 and a central controller 6, The needle sending mechanism 1 and the needle dropping mechanism 2 are connected through the needle sending guide rail 5, and the needle pushing mechanism 3 is arranged on the working position of the needle dropping mechanism 2 and the working position of the needle pressing mechanism 4 so as to move back and forth. The controller 6 is in signal connection with the needle feeding mechanism 1 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com