Fluorine-containing polymer electrolytes and preparation methods and applications thereof

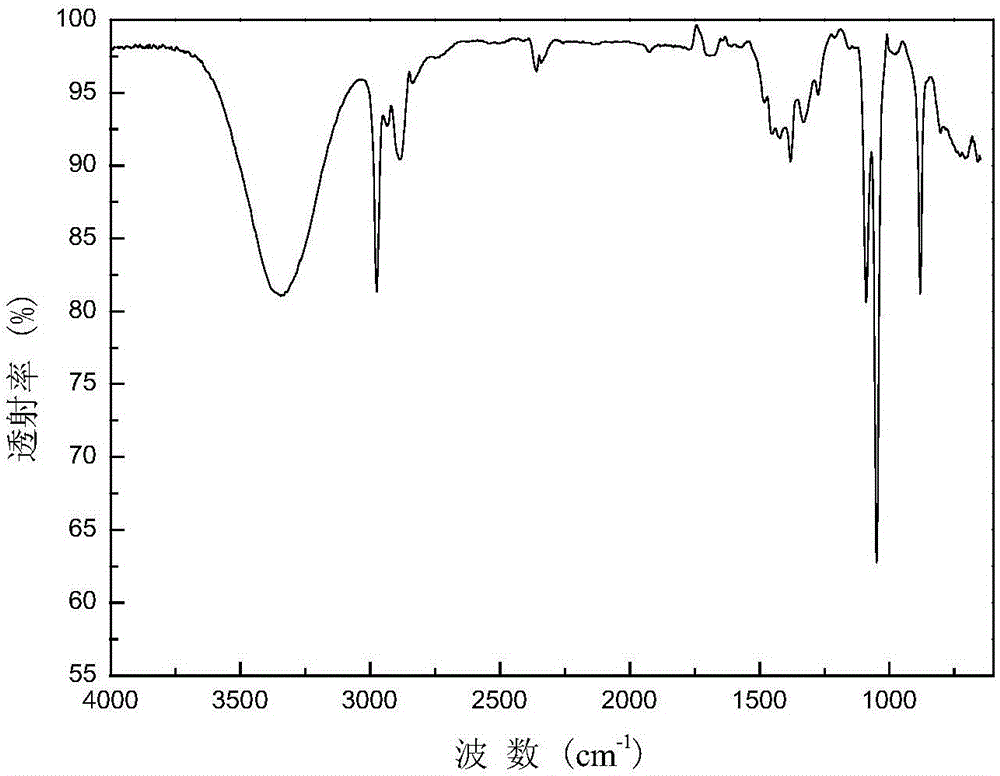

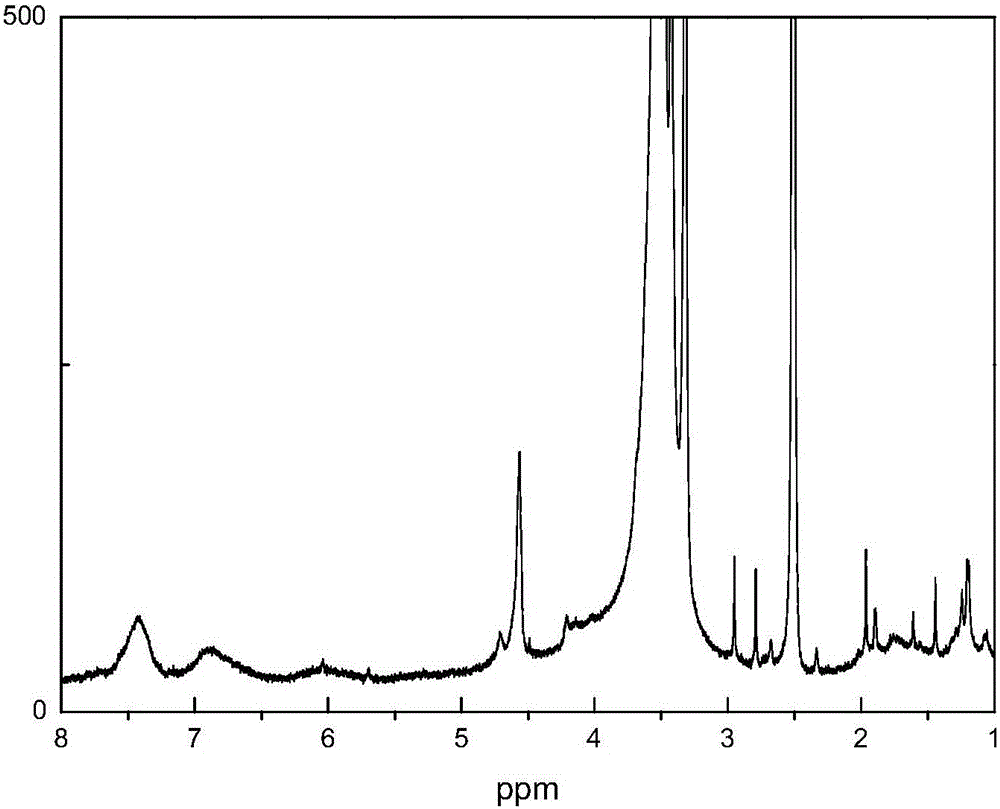

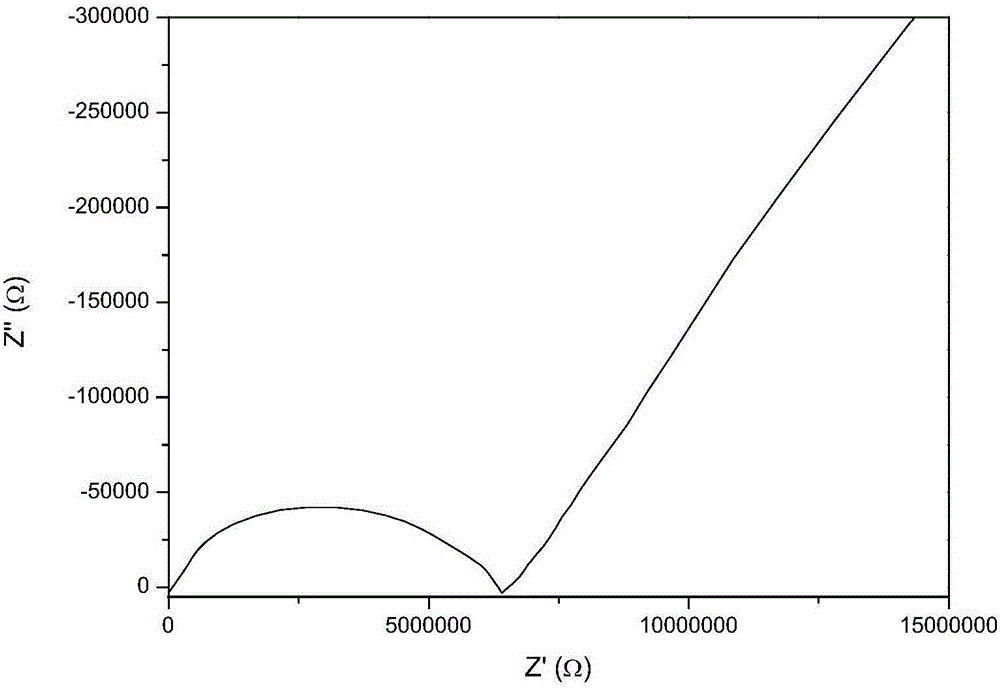

A technology of electrolyte and polymer, which is applied in the field of new fluorine-containing polymer electrolyte and its synthesis, can solve the problems of easy water absorption and low conductivity, and achieve the effect of improving conductivity, reducing interaction between ions, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0045] Specific implementation mode 1: The preparation method of fluoropolymer electrolyte I in this implementation mode is implemented according to the following steps:

[0046] 1. Under the protective atmosphere of inert gas, add sodium p-styrenesulfonate and polyethylene glycol methacrylate into the solvent according to the molar ratio of 1:1~3, and then add the initiator, at 70~80℃ After reacting at high temperature for 10 minutes, hexafluorobutyl methacrylate was added, and the reaction was continued for 15 to 30 minutes to obtain a polymerized product;

[0047] 2. Cast the polymer product into a polytetrafluoroethylene mold, dry and form a film to obtain the fluorine-containing polymer electrolyte I;

[0048] Wherein the hexafluorobutyl methacrylate accounts for 10%-30% of the molar content of the total reactants in step 1.

[0049] The reaction equation of the present embodiment polysodium p-styrene sulfonate-polyethylene glycol methacrylate-hexafluorobutyl methacrylat...

specific Embodiment approach 2

[0051] Specific implementation mode 2: The preparation method of the fluorine-containing polymer electrolyte II in this implementation mode is implemented according to the following steps:

[0052] 1. Under the protective atmosphere of inert gas, add sodium p-styrenesulfonate and polyethylene glycol methacrylate into the solvent according to the molar ratio of 1:1~3, and then add the initiator, at 70~80℃ After reacting at high temperature for 10 minutes, hexafluorobutyl methacrylate and ethylene carbonate were added, and the reaction was continued for 15 to 30 minutes to obtain a polymerized product;

[0053]2. Cast the polymer product into a polytetrafluoroethylene mold, dry and form a film to obtain the fluorine-containing polymer electrolyte II;

[0054] Wherein in step 1, hexafluorobutyl methacrylate accounts for 10%-15% of the molar content of the total reactants, and ethylene ethylene carbonate accounts for 10%-15% of the molar content of the total reactants.

[0055] T...

specific Embodiment approach 3

[0057] Specific embodiment three: the preparation method of the fluorine-containing polymer electrolyte III in this embodiment is implemented according to the following steps:

[0058] 1. Under the protective atmosphere of inert gas, add sodium p-styrenesulfonate and polyethylene glycol methacrylate into the solvent according to the molar ratio of 1:1~3, and then add the initiator, at 70~80℃ After reacting at high temperature for 10 minutes, hexafluorobutyl methacrylate was added, and the reaction was continued for 15 to 30 minutes to obtain a polymerized product;

[0059] 2. Add LiCl to deionized water to obtain a lithium salt solution, and then add the polymer product to the lithium salt solution for lithium salt replacement to obtain a replaced solution;

[0060] 3. Perform dialysis on the replaced solution, and then dry it in a vacuum oven after purging to obtain a dry polymer electrolyte;

[0061] 4. Dissolve the dried polymer electrolyte obtained in step 3 in N,N-dimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com