Method for effectively improving ionic conductivity of perfluorosulfonate membrane

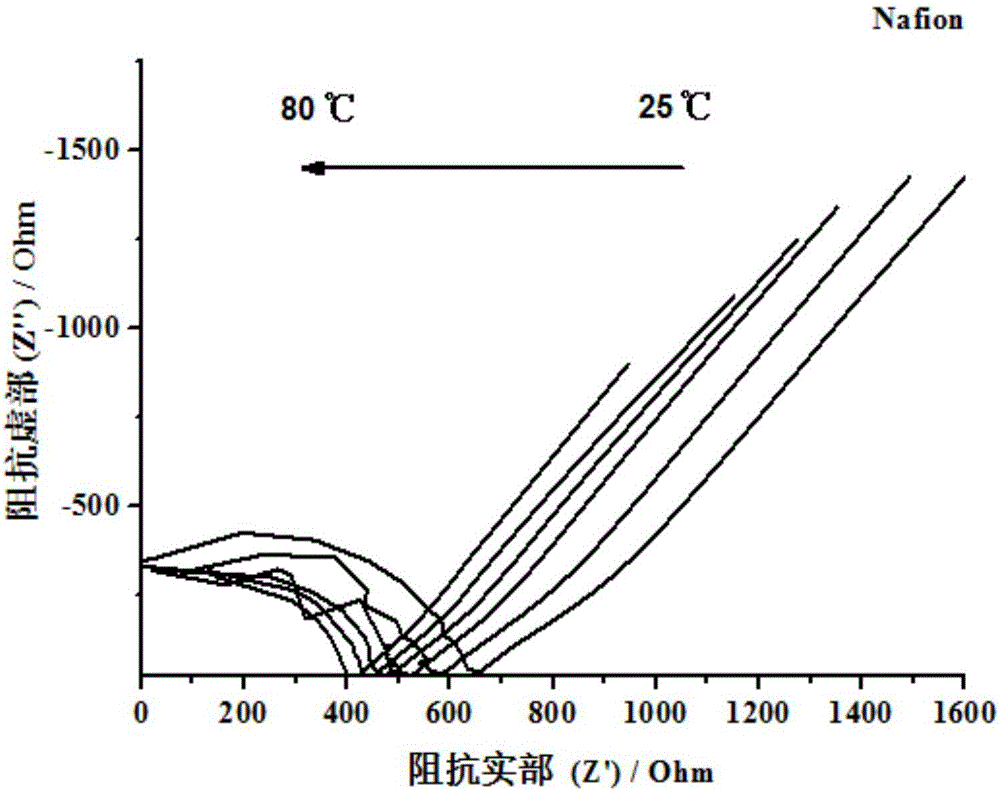

A technology of perfluorosulfonic acid membrane and ionic conductivity, which is applied in fuel cell parts, circuits, electrical components, etc., can solve the problems of high price, poor high temperature resistance, and limited promotion of Nafion membrane, and reduce resistance , post-processing convenience, the effect of improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1SGO

[0022] Add 20 mL of 3% NaOH solution and 0.3 g of p-aminobenzenesulfonic acid (SA) into a 100 mL beaker, and dissolve 0.3 g of SA in a warm water bath. Then add 0.06g NaNO to the above solution at room temperature 2 , when NaNO 2 After dissolving in the mixed solution, the solution was poured into 20 mL of ice water containing 1 mL of concentrated HCl under stirring condition, and the temperature was kept in the ice water bath for 30 min, and then the aryl diazonium salt was formed. The aryl diazonium salt solution prepared above was added dropwise into GO aqueous solution containing 250 mg GO, and the mixed solution was reacted in a water bath at 15 °C for 14 h. Then it was separated by centrifugation, washed with deionized water until neutral, and then freeze-dried.

Embodiment 2

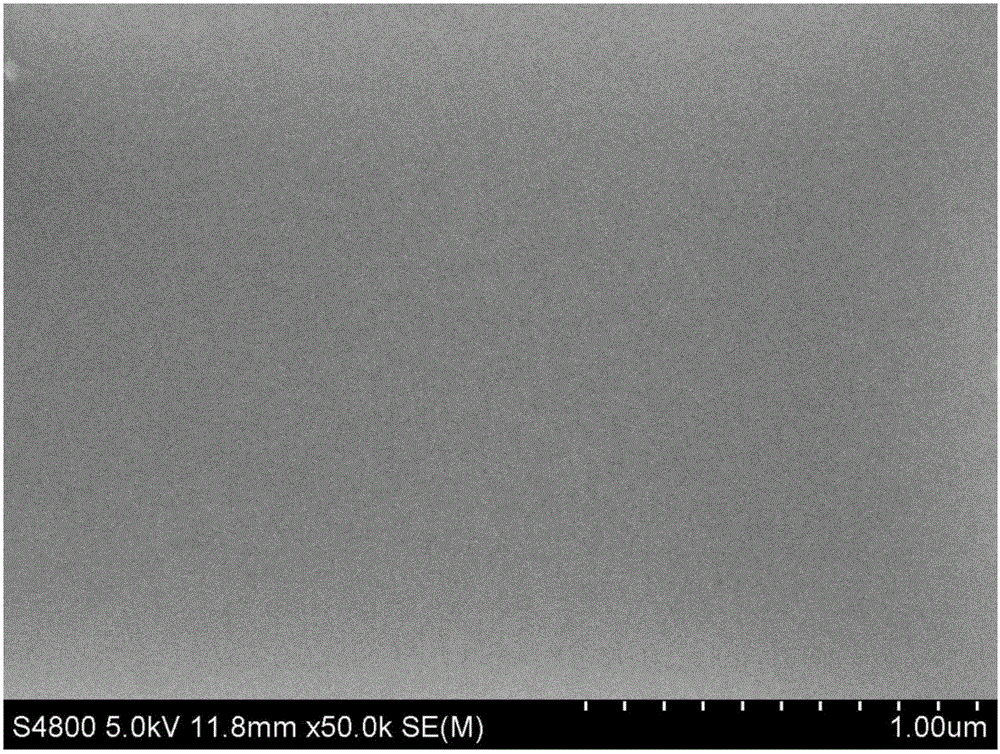

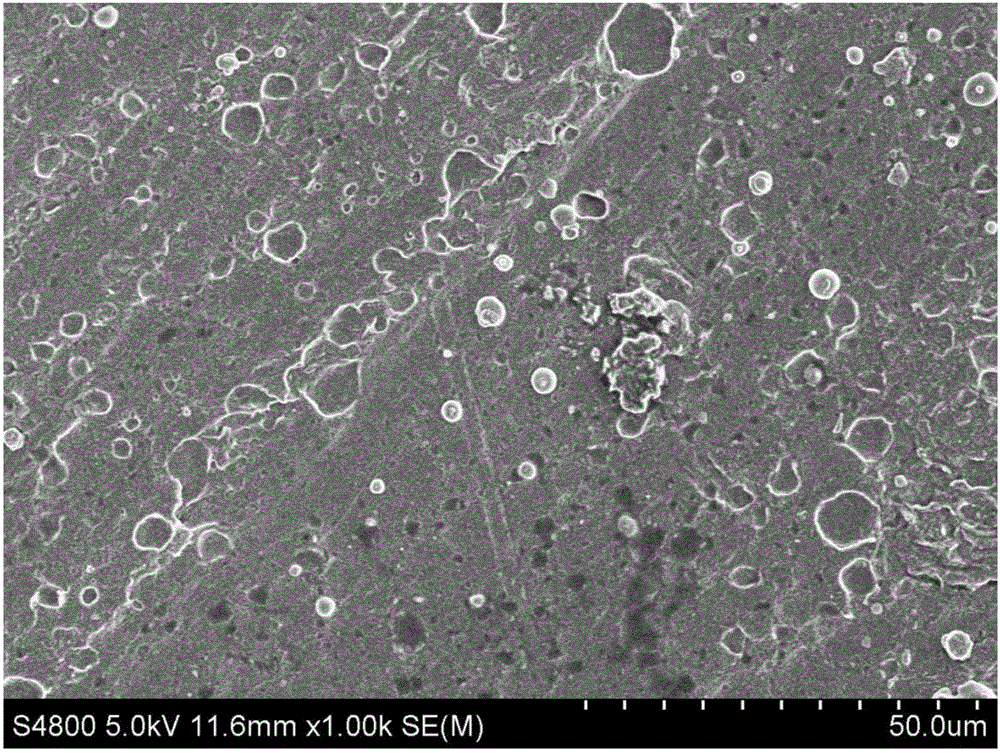

[0023] The preparation of embodiment 2SGO / Nafion composite membrane

[0024] 1.1 Preparation of Nafion / DMF solution

[0025] Evaporate the solvent from the Nafion solution at 80°C to obtain a Nafion solid, which is formulated into a 0.04g / mL solution, and dispersed evenly by ultrasonication at a frequency of 70HZ and a temperature of 65°C.

[0026] 1.2 Preparation of SGO / DMF solution

[0027] The sulfonated graphene oxide SGO obtained after freeze-drying in the above experiments was dissolved in DMF to prepare a 0.03 g / mL solution, and then dispersed evenly by ultrasonic at a frequency of 70 Hz and a temperature of 65 °C.

[0028] 1.3 SGO / Nafion composite membrane

[0029] According to the quality of the contained SGO, mix the above-mentioned Nafion / DMF solution and SGO / DMF solution to prepare mixed membrane solutions with ratios of 0%, 1%, 3%, 5%, and 8%, and disperse them uniformly by ultrasonic at a frequency of 70HZ , the temperature is 65°C, the mixed dispersion is pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com