Lithium-ion battery negative electrode sheet, preparation method and application, lithium-ion battery

A technology for lithium ion batteries and negative electrode sheets, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of inability to achieve uniform lithium supplementation, lithium deposition of negative electrode sheets, deformation, etc., to improve chemical stability and lithium supplementation. Accurate and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

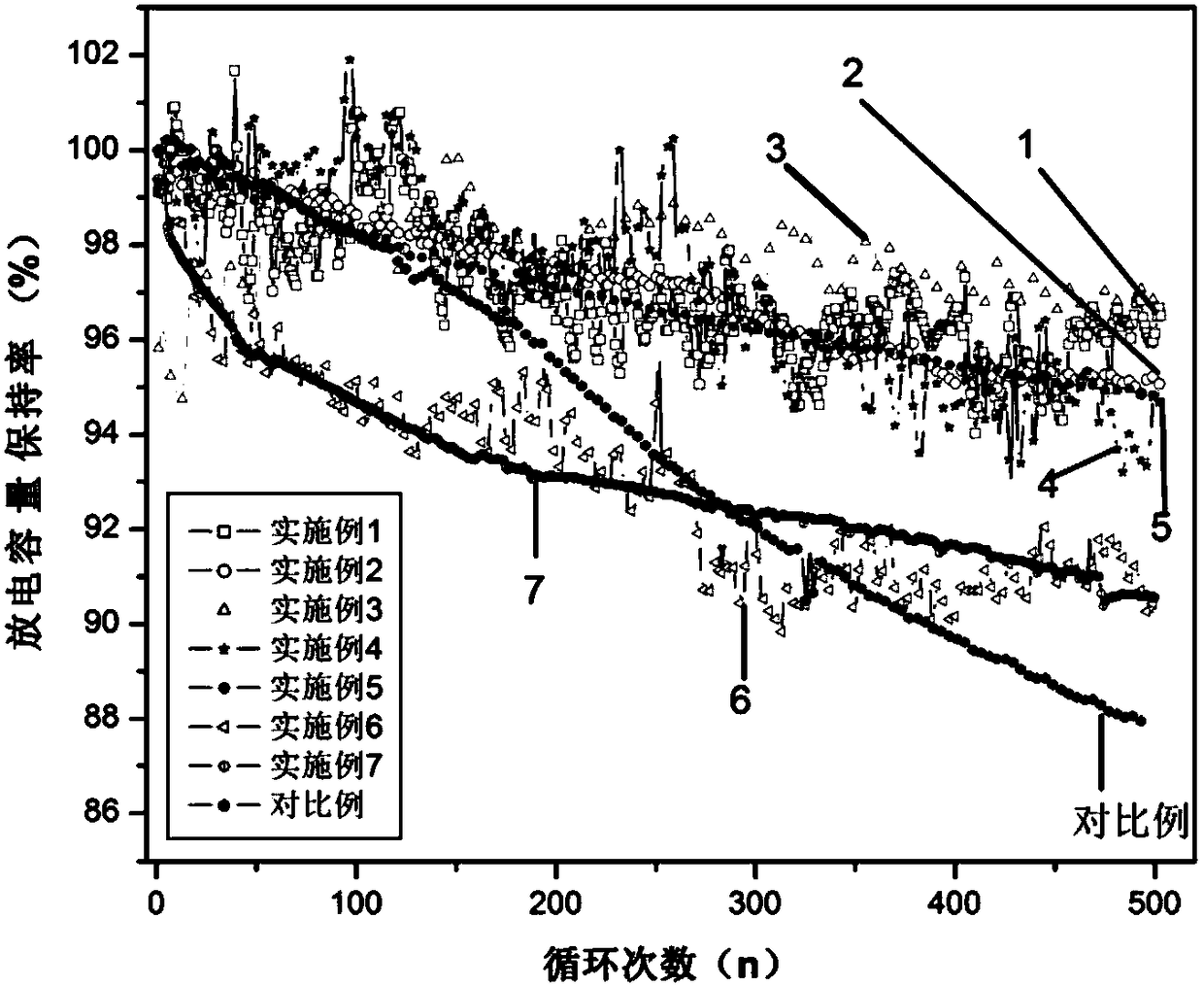

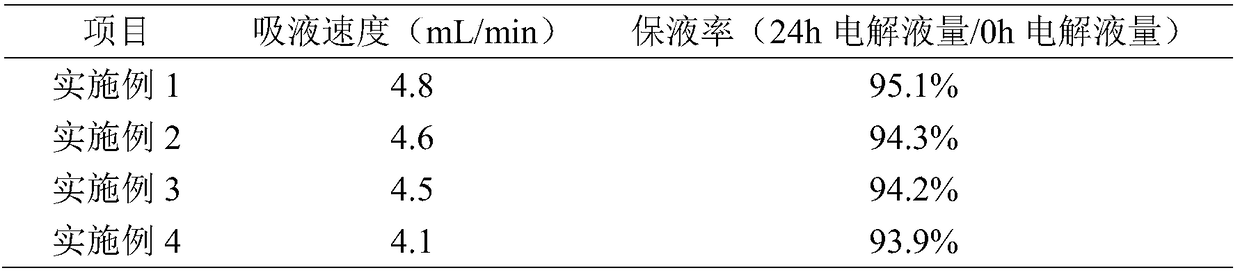

Examples

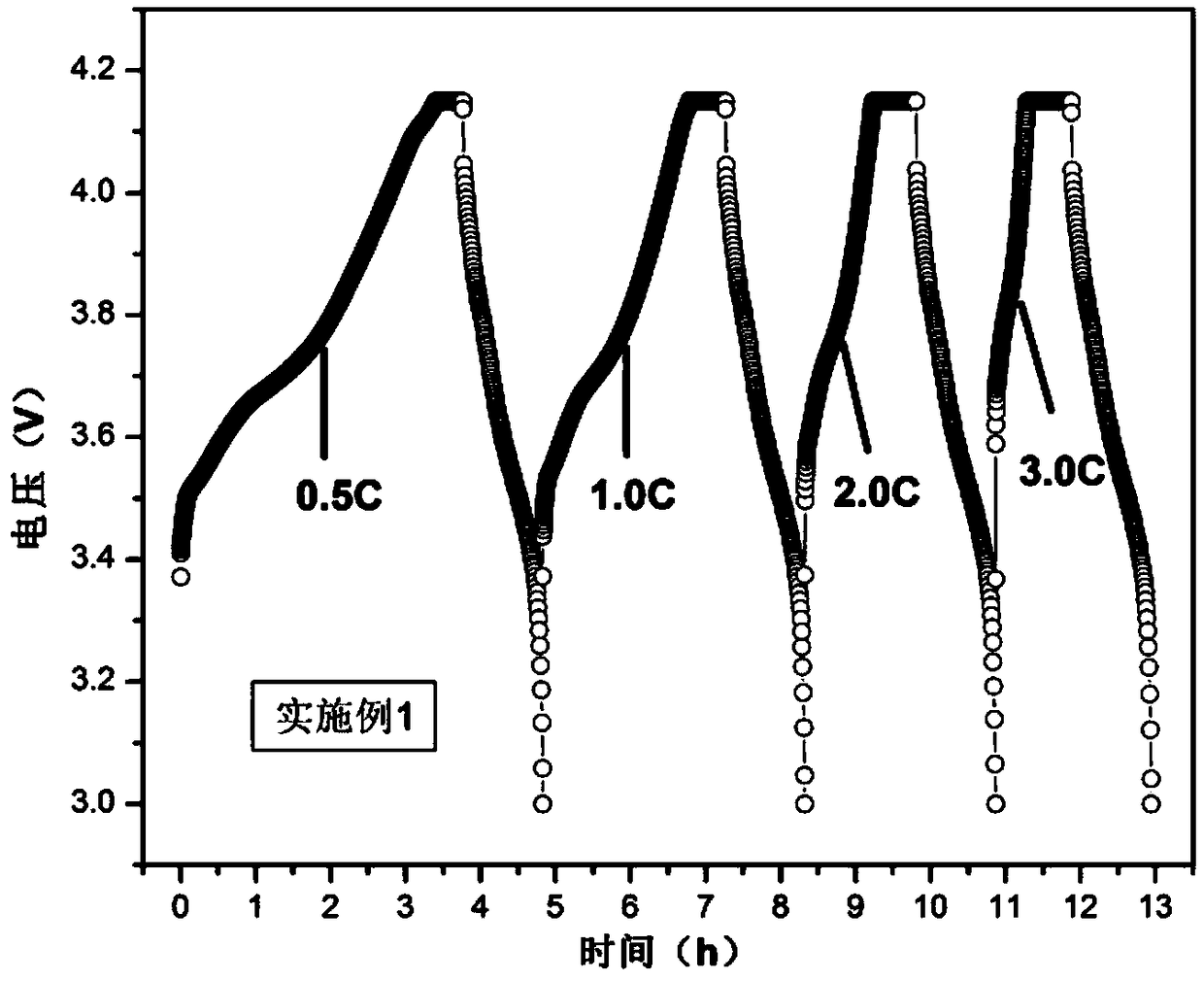

Embodiment 1

[0033] A lithium ion battery negative electrode sheet, the preparation method thereof comprises the following steps:

[0034] 1) Preparation of lithium-containing coating

[0035] In a glove box under an argon atmosphere, 10 g of polypropylene carbonate (molecular weight 50,000) weighed was dissolved in 100 g of ethyl methyl carbonate (EMC), and stirred for 15 min at 20 rpm to obtain solution A; 2 g of phenyl Lithium powder was added to solution A, stirred at 10 rpm for 30 min, and filtered; the filter residue was taken, washed with deionized water, and then the filter residue was dried at 70°C under argon protection at 70°C to obtain 12 g of lithium-containing coating;

[0036] 2) Preparation of negative electrode sheet for lithium battery

[0037] 10g of lithium-containing coating and 1g of sodium dodecylbenzenesulfonate that were weighed were added to 100g of chloroform solvent, and the mixture was uniformly mixed to obtain a spray solution; the electrospinning technology ...

Embodiment 2

[0040] A lithium ion battery negative electrode sheet, the preparation method thereof comprises the following steps:

[0041] 1) Preparation of lithium-containing coating

[0042] In a glove box under an argon atmosphere, 8 g of polymethyl methacrylate (molecular weight: 100,000) was weighed and dissolved in 100 g of ethyl methyl carbonate (EMC), and stirred for 15 min at 20 rpm to obtain solution A; Butyllithium powder was added to solution A, stirred at 10 rpm for 30 min, and filtered; the filter residue was taken, washed with deionized water, and then the filter residue was spray-dried at 70°C under argon protection at 70°C to obtain a lithium-containing coating 9g;

[0043] 2) Preparation of negative electrode sheet for lithium battery

[0044]The 5g lithium-containing coating and 0.5g sodium dodecylbenzene sulfonate that were weighed were added to 100g carbon tetrachloride solvent, and the mixture was uniformly mixed to obtain a spray solution; Electrospinning technolog...

Embodiment 3

[0047] A lithium ion battery negative electrode sheet, the preparation method thereof comprises the following steps:

[0048] 1) Preparation of lithium-containing coating

[0049] In a glove box in an argon atmosphere, 15g of polymethylsiloxane (molecular weight: 100,000) was weighed and dissolved in 100g of ethyl methyl carbonate (EMC), and stirred at 20rpm for 15min to obtain solution A; Lithium ethyl borohydride powder was added to solution A, stirred at 10 rpm for 30 min, and filtered; the filter residue was taken, washed with deionized water, and then the filter residue was spray-dried at 70 ° C under argon protection at 70 ° C to obtain lithium-containing Coating 25g;

[0050] 2) Preparation of negative electrode sheet for lithium battery

[0051] 20g of lithium-containing coating and 2g of sodium dodecylbenzenesulfonate were added into 100g of toluene solvent, and mixed to obtain a spray solution; the electrospinning technology (voltage 30kV, spray speed 0.01mm / s) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com