Lithium ion battery negative plate as well as preparation method and application thereof and lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as inability to achieve uniform lithium replenishment, negative electrode sheet lithium separation, deformation, etc., to improve chemical stability and lithium replenishment capacity Precise, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

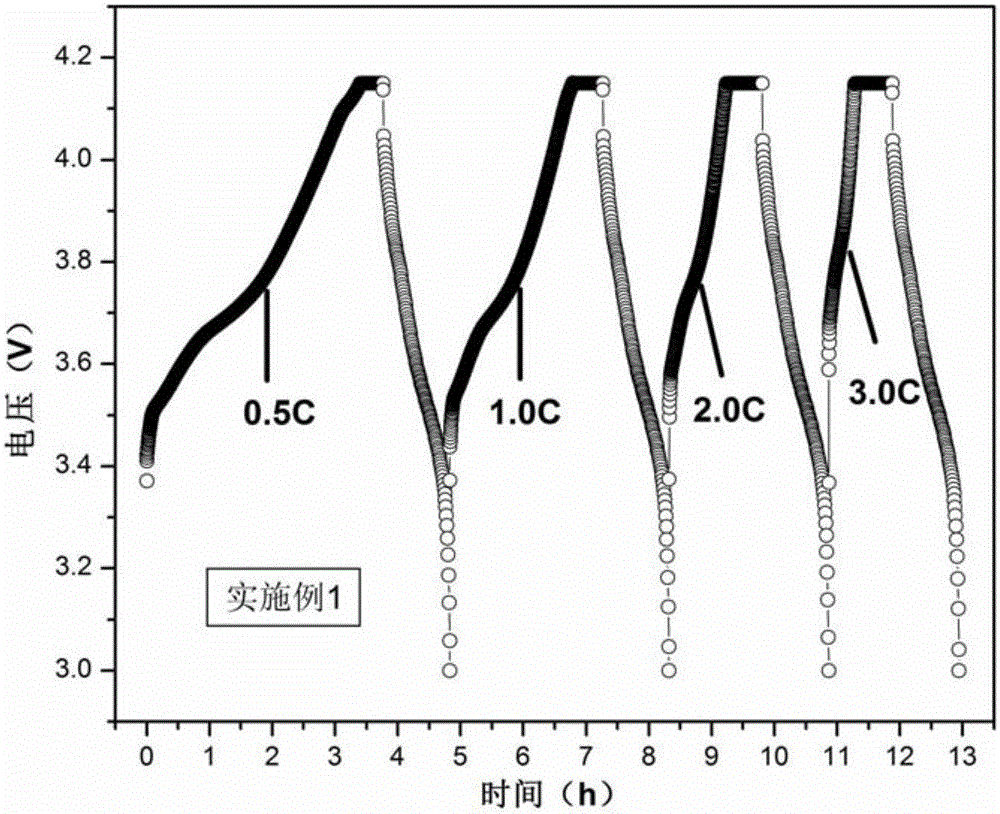

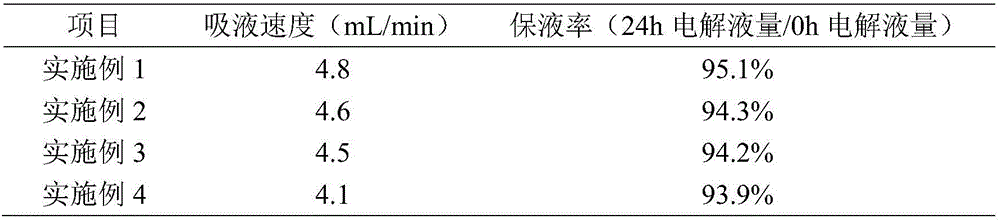

Embodiment 1

[0033] Lithium ion battery negative plate, its preparation method comprises the following steps:

[0034] 1) Preparation of lithium-containing coatings

[0035] In a glove box under an argon atmosphere, 10 g of polypropylene carbonate (molecular weight: 50,000) was dissolved in 100 g of ethyl methyl carbonate (EMC), and stirred at 20 rpm for 15 min to obtain solution A; 2 g of phenyl Add lithium powder into solution A, stir at 10 rpm for 30 minutes, and filter; take the filter residue, wash it with deionized water, and then dry the filter residue at 70°C under the protection of argon at 70°C to obtain 12g of lithium-containing coating;

[0036] 2) Preparation of negative electrode sheet for lithium battery

[0037] Add 10g of lithium-containing coating and 1g of sodium dodecylbenzenesulfonate into 100g of chloroform solvent, and mix well to obtain a spraying solution; use electrospinning technology (voltage 20kV, spraying speed 0.02mm / s) to spray The solution is evenly spray...

Embodiment 2

[0040] Lithium ion battery negative plate, its preparation method comprises the following steps:

[0041] 1) Preparation of lithium-containing coatings

[0042] In a glove box with an argon atmosphere, 8 g of polymethyl methacrylate (molecular weight: 100,000) was dissolved in 100 g of ethyl methyl carbonate (EMC), and stirred at 20 rpm for 15 min to obtain solution A; Add butyl lithium powder into solution A, stir at 10 rpm for 30 minutes, and filter; take the filter residue, wash it with deionized water, and then spray dry the filter residue at 70°C under the protection of argon at 70°C to obtain lithium-coated 9g;

[0043] 2) Preparation of negative electrode sheet for lithium battery

[0044]Add 5g of the lithium-containing coating and 0.5g of sodium dodecylbenzenesulfonate into 100g of carbon tetrachloride solvent, mix well to obtain a spraying solution; adopt electrospinning technology (voltage 10kV, spraying speed 0.03mm / s) Spray the spray liquid evenly on the surfa...

Embodiment 3

[0047] Lithium ion battery negative plate, its preparation method comprises the following steps:

[0048] 1) Preparation of lithium-containing coatings

[0049] In a glove box under an argon atmosphere, 15 g of polymethylsiloxane (molecular weight: 100,000) was dissolved in 100 g of ethyl methyl carbonate (EMC), and stirred at 20 rpm for 15 min to obtain solution A; Add lithium ethyl borohydride powder into solution A, stir at 10 rpm for 30 minutes, and filter; take the filter residue, wash it with deionized water, and then spray-dry the filter residue at 70°C under the protection of argon at 70°C to obtain lithium-containing Covering 25g;

[0050] 2) Preparation of negative electrode sheet for lithium battery

[0051] Add 20g of lithium-containing coating and 2g of sodium dodecylbenzenesulfonate into 100g of toluene solvent, and mix well to obtain a spraying solution; use electrospinning technology (voltage 30kV, spraying speed 0.01mm / s) to spray The solution was uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com