Direct high back pressure heat supply system of indirect air cooling unit

A technology for air-cooled units and heating systems, applied in lighting and heating equipment, steam/steam condensers, etc., can solve the problem of inability to effectively take away heat from low-pressure cylinder exhaust, reduced circulating water flow in unit condensers, and high back pressure. The heating unit must be shut down and other problems to achieve the effect of improving the heating capacity of the enterprise, the structure is simple, and the safety is ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

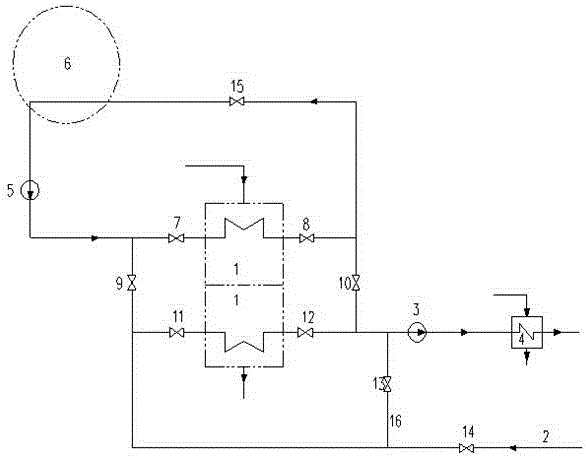

[0019] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a condenser 1, and the internal circulating water pipe of the condenser 1 is evenly divided into two independent parts, wherein the water inlet pipe on one side is connected to the heat network return pipe 2, and the water outlet pipe is connected to the heat network through the heat network circulation pump 3. Network heater 4; the water inlet pipe on the other side is connected to the inter-cooling tower 6 through the frequency conversion circulating water pump 5, and the outlet pipe is connected to the water inlet pipe of the inter-cooling tower 6; valves A7 are respectively installed on the water inlet pipes on both sides of the condenser 1 , valve E11, valve B8 and valve F12 are respectively installed on the outlet pipe; the water inlet pipe and outlet pipe on both sides of the condenser 1 are connected by pipelines, and valve C9 and valve D10 are respectively in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com