Elastic putty composition for wind turbine blade

A technology of elastic putty and wind turbine blades, applied in the direction of filling slurry, etc., can solve the problems of burden and high price, and achieve the effect of low cost, improved flexibility, and easier control of operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

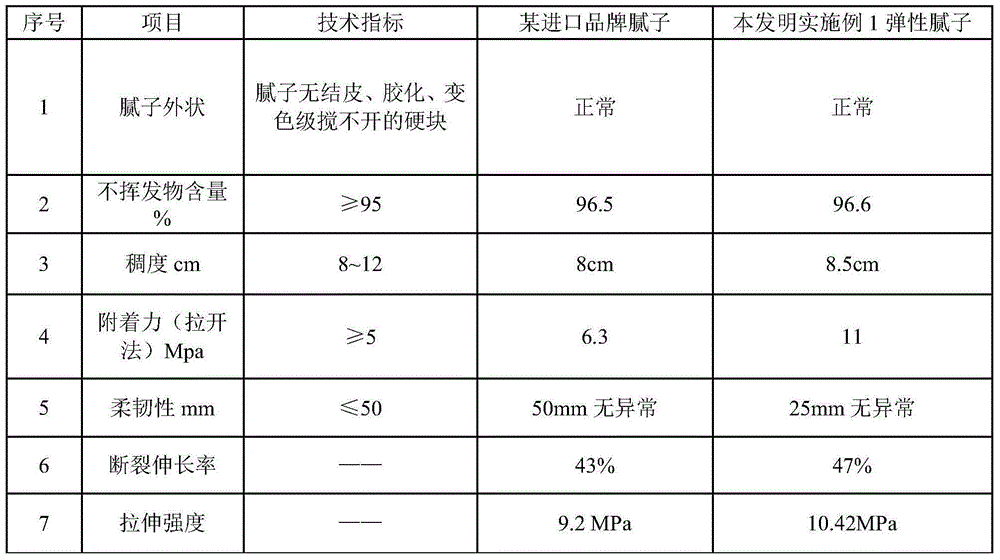

Examples

preparation example Construction

[0025] Preparation of Modified Polyol Resin

[0026] 100 parts by weight of the polyol resin purchased from BASF company HP 4000D with 35 parts by weight supplied by BAYER 1100 parts by weight of polyester resin and 7.5 parts by weight of polyaspartic acid resin purchased from BAYER in Germany were polymerized in a reactor at 200° C. for 5 hours under normal pressure to obtain a modified polyol resin.

Embodiment 1

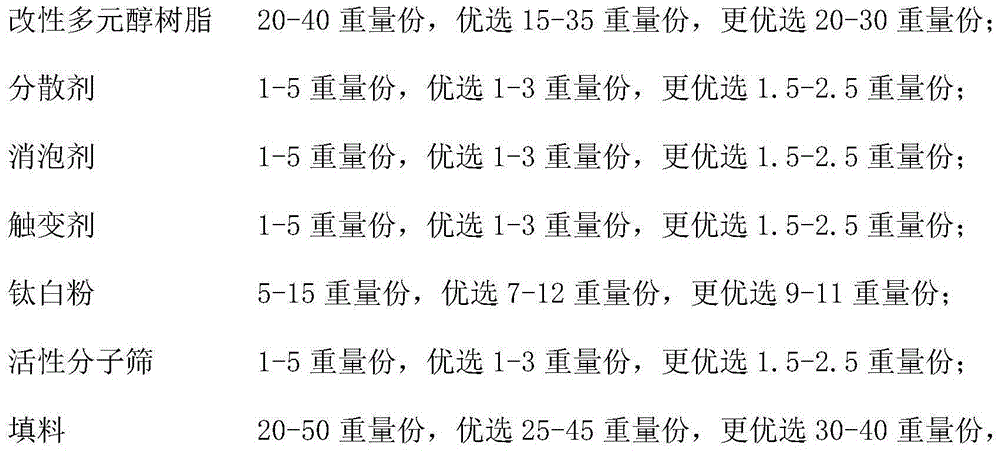

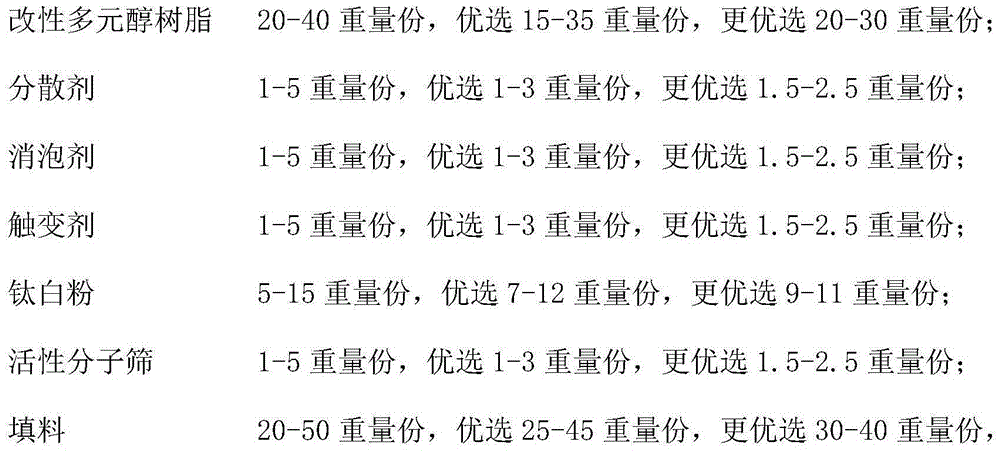

[0028] The modified polyol resin prepared above

[0029] Put the above-mentioned raw materials in the weight ratio into the internal mixer and mix thoroughly, then perform defoaming treatment to prevent the generation of air bubbles and pinholes. The defoaming is carried out at about -0.1MPa for 5-10 minutes, and the rotation speed of the stirring shaft of the internal mixer is maintained at about 400rpm.

Embodiment 2

[0031] The modified polyol resin prepared above

[0032] Put the above-mentioned raw materials in the weight ratio into the internal mixer and mix thoroughly, then perform defoaming treatment to prevent the generation of air bubbles and pinholes. The defoaming is carried out at about -0.1MPa for 5-10 minutes, and the rotation speed of the stirring shaft of the internal mixer is maintained at about 400rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com