High-elasticity high/low-temperature-resistant road joint sealing material and preparation method thereof

A high-low temperature, high-elasticity technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor foundation waterproofing, temperature-sensitive asphalt joint fillers, and easy aging, etc., to achieve easy industrial production and application, increase The effect of high and low temperature resistance and high elastic recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

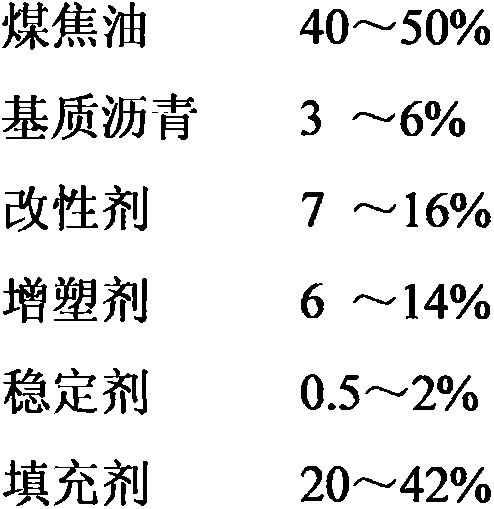

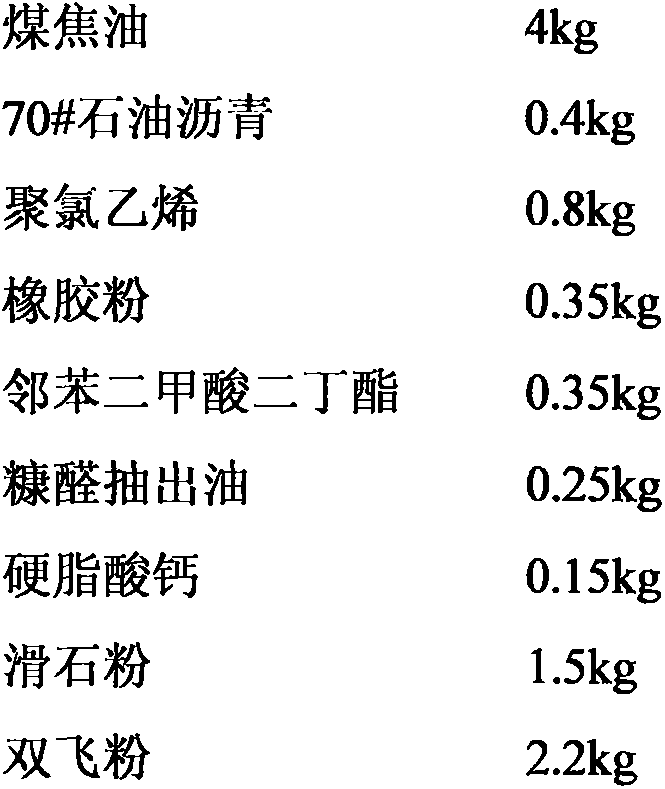

[0014] Prepare 10kg road joint filler of the present invention, its quality proportioning is as follows:

[0015]

[0016] According to the above mass ratio, in the first stage, coal tar is added to the stirring tank, and the coal tar is heated to 110°C at a stirring speed of 120 rpm, and dehydrated for 1.5 hours, and then the base asphalt and modifier rubber are added in sequence. Powder, heat the mixture to 180°C, after swelling for 1 hour, stop heating; in the second stage, change the stirring speed to 200 rpm, cool the mixture to 135°C, then add stabilizer, plasticizer, and modifier in sequence Polyvinyl chloride, keep the temperature at 140°C, stir and plasticize for 0.5h, finally add filler, stir evenly, cool to 105°C, and pack it out to obtain a road joint filler with high elasticity and high and low temperature resistance.

Embodiment 2

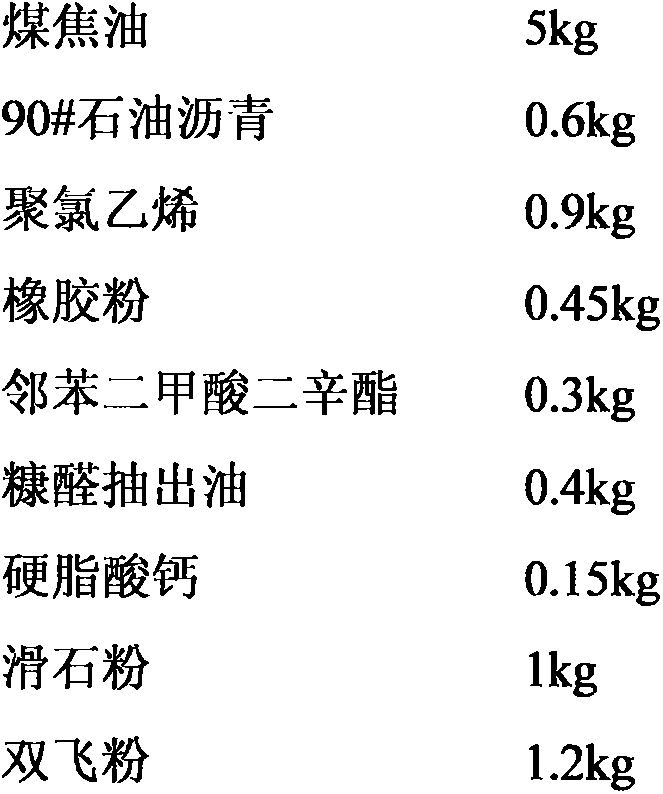

[0018] Prepare 10kg road joint filler of the present invention, its quality proportioning is as follows:

[0019]

[0020] According to the above ratio, in the first stage, add coal tar to the stirring tank, heat the coal tar to 110°C at a stirring speed of 120 rpm, keep it dehydrated for 1.5 hours, and then add base asphalt and modifier rubber powder in sequence , heat the mixture to 180°C, swell for 1.5 hours, then stop heating; in the second stage, change the stirring speed to 200 rpm, cool the mixture to 135°C, and then add stabilizer, plasticizer, and modifier in sequence Polyvinyl chloride, keep the temperature at 140°C, stir and plasticize for 0.5h, finally add filler, stir evenly, cool to 105°C, and pack it out to obtain a road joint filler with high elasticity and high and low temperature resistance.

Embodiment 3

[0022] Prepare 10kg road joint filler of the present invention, its quality proportioning is as follows:

[0023]

[0024] According to the above ratio, in the first stage, add coal tar to the stirring tank, heat the coal tar to 110°C at a stirring speed of 120 rpm, keep it dehydrated for 1.5 hours, and then add base asphalt and modifier rubber powder in sequence , and heat the mixture to 180°C, after swelling for 1.5h, stop heating; in the second stage, change the stirring speed to 200 rpm, cool the mixture to 135°C, then add stabilizer, plasticizer, modified Add polyvinyl chloride, keep the temperature at 140°C, stir and plasticize for 0.5h, finally add filler, stir evenly, cool to 105°C, and pack it out to obtain a road joint filler with high elasticity and high and low temperature resistance .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com