Preparation method and application of fluorescent copper cluster with stable silane

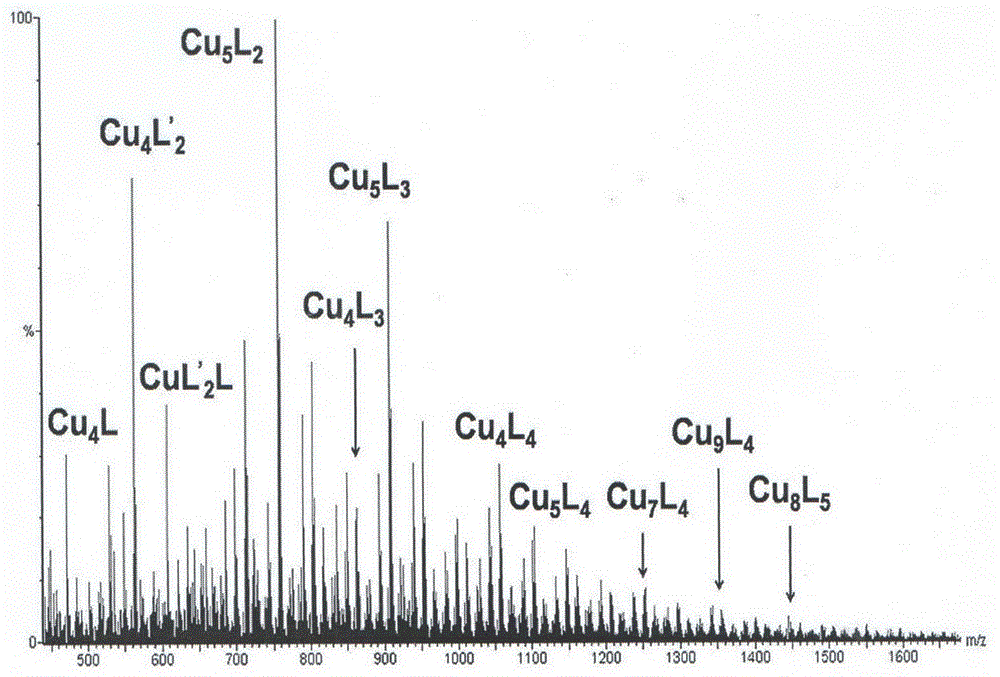

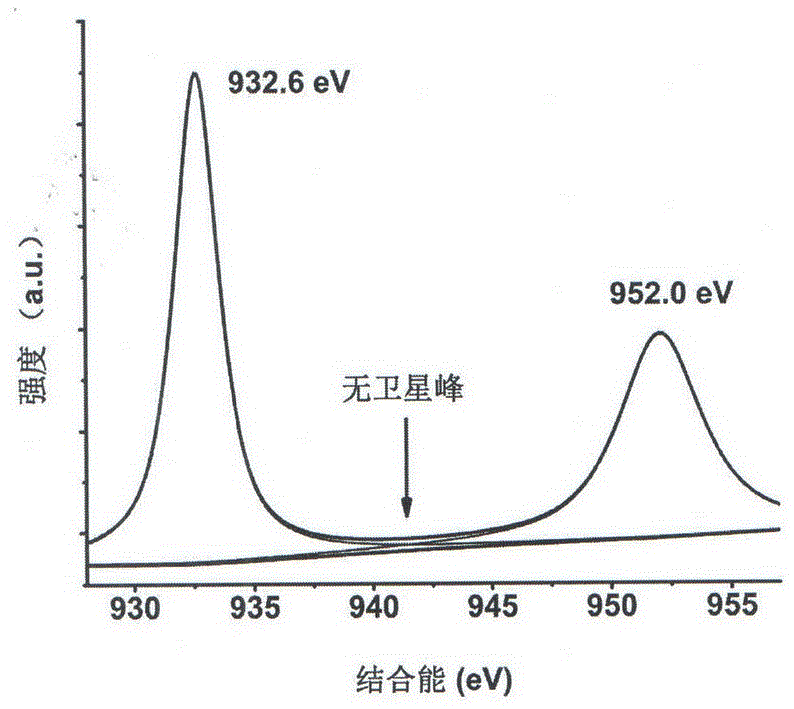

A fluorescent copper and cluster technology, which is applied in the field of fluorescence detection, can solve the problems of loss of photoluminescence and few research reports on the synthesis of copper clusters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Add 120 μL of 2-mercaptopropyltrimethoxysilane with a mass concentration of 95% to 6 mL of 0.005 mol / L copper acetate tetrahydrofuran solution, and stir at room temperature for 3 hours to obtain a nearly colorless solution;

[0019] b. Under stirring, quickly add 200 μL of 1.591 mol / L sodium cyanoborohydride tetrahydrofuran solution to the solution in step a. After the addition is complete, continue stirring for 48 hours to obtain a light yellow mixed solution;

[0020] c. Centrifuge the mixed solution obtained in step b at 8000 rpm for 5 minutes, wash the obtained precipitate with absolute ethanol, and cycle this procedure twice to obtain a copper cluster precipitate;

[0021] d. Mix the copper cluster precipitate obtained in step c with tetrahydrofuran and disperse it with ultrasonic for 5 minutes to obtain a uniformly dispersed fluorescent copper cluster system.

Embodiment 2

[0023] a. Add 120 μL of 2-mercaptopropyltrimethoxysilane with a mass concentration of 95% to 6 mL of 0.005 mol / L copper acetate tetrahydrofuran solution, and stir at room temperature for 3 hours to obtain a nearly colorless solution;

[0024] b. Under stirring, quickly add 250 μL of 1.591 mol / L sodium cyanoborohydride tetrahydrofuran solution to the solution in step a. After the addition is complete, continue stirring for 48 hours to obtain a light yellow mixed solution;

[0025] c. Centrifuge the mixed solution obtained in step b at 8000rpm for 5 minutes, wash the obtained precipitate with absolute ethanol, and cycle this procedure twice to obtain the copper cluster precipitate;

[0026] d. Mix the copper cluster precipitate obtained in step c with anhydrous methanol and ultrasonically disperse it for 5 minutes to obtain a uniformly dispersed fluorescent copper cluster system.

Embodiment 3

[0028] a. Add 120 μL of 2-mercaptopropyltrimethoxysilane with a mass concentration of 95% to 6 mL of 0.005 mol / L copper acetate tetrahydrofuran solution, and stir at room temperature for 3 hours to obtain a nearly colorless solution;

[0029] b. Under stirring, quickly add 300 μL of 1.591 mol / L sodium cyanoborohydride tetrahydrofuran solution to the solution in step a. After the addition is complete, continue stirring for 48 hours to obtain a light yellow mixed solution;

[0030] c. Centrifuge the mixed solution obtained in step b at 8000rpm for 5 minutes, wash the obtained precipitate with absolute ethanol, and cycle this procedure twice to obtain the copper cluster precipitate;

[0031] d. Mix the copper cluster precipitate obtained in step c with absolute ethanol and disperse it with ultrasonic for 5 minutes to obtain a uniformly dispersed fluorescent copper cluster system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com