Beneficiation method for effectively recovering extremely-fine-particle molybdenum ore

A mineral processing method and fine-grained technology, which is applied in the field of mineral processing for efficient recovery of molybdenum, can solve problems such as the inability to recover fine-grained molybdenum minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

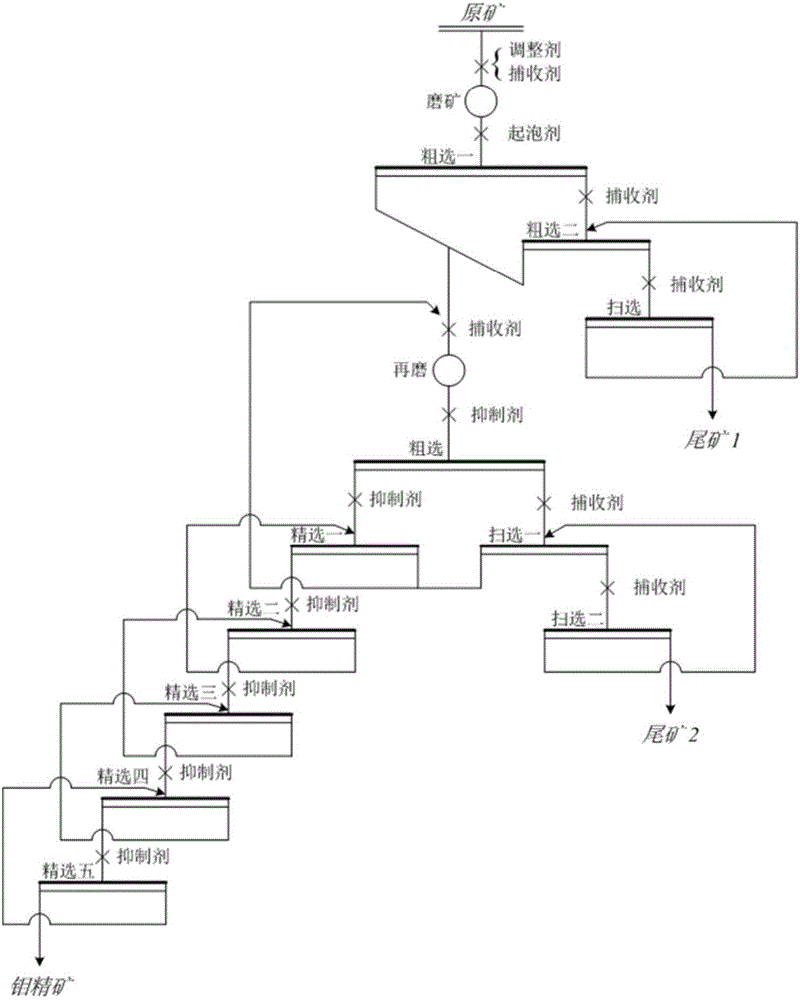

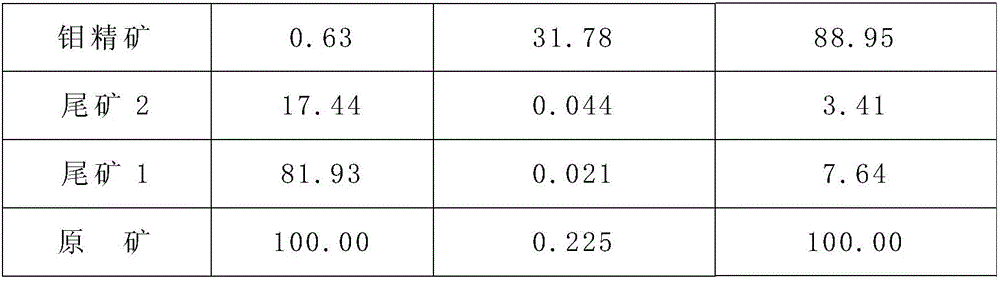

[0037] A porphyry-type molybdenum deposit in Inner Mongolia, the metal minerals in the ore mainly include pyrite, molybdenite, magnetite, pyrrhotite, chalcopyrite, etc.; the gangue minerals mainly include quartz, potassium feldspar, and albite , Muscovite, Sericite, Biotite, etc. The raw ore contains 0.225% molybdenum, and the oxidation rate of molybdenum is 5.85%. Molybdenite is mainly micro-fine-grained molybdenite (referred to as fine-grained molybdenite). The particle size of molybdenite in ore is generally 0.005-0.030mm, and the occupancy rate of molybdenite in the -0.020mm particle size reaches 51.60. %. Such as figure 1 Shown technological process, concrete technological parameter is:

[0038] (1) Grinding process: Put the fine-grained molybdenum ore, 3000 g / ton of sodium sulfide regulator, and 1600 g / ton of diesel oil into the ball mill, add water to carry out wet grinding to obtain ore pulp, control the grinding concentration to 55%, and grind The ore fineness is ...

Embodiment 2

[0048]Inner Mongolia processes 100t / d of a certain porphyry-type molybdenum ore. The metal minerals in the ore mainly include pyrite, molybdenite, magnetite, pyrrhotite, chalcopyrite, etc.; the gangue minerals are mainly quartz, potassium Albite, albite, muscovite, sericite, biotite, etc. The raw ore contains 0.154% molybdenum, and the oxidation rate of molybdenum is 4.65%. Molybdenite is mainly micro-fine-grained molybdenite (referred to as fine-grained molybdenum ore). The particle size of molybdenite in the ore is generally 0.001-0.020mm, and the occupancy rate of molybdenite in the -0.020mm particle size reaches 60.57 %. Such as figure 1 Shown technological process, concrete technological parameter is:

[0049] (1) Grinding process: Put the fine-grained molybdenum ore, 4000 g / t sodium sulfide regulator and 1000 g / t kerosene into the ball mill, add water for wet grinding, control the grinding concentration to 55%, and the grinding fineness -0.074mm accounted for 91%.

...

Embodiment 3

[0058] A porphyry-type molybdenum deposit in Shaanxi, the metal minerals in the ore mainly include molybdenite, magnetite, pyrite, pyrrhotite, and occasionally chalcopyrite; the gangue minerals are mainly quartz, diopside, calcite, Sericite, fluorite, feldspar, chlorite, serpentine, talc and biotite, etc. The raw ore contains 0.11% molybdenum, and the oxidation rate of molybdenum is 6.52%. Molybdenite is mainly micro-fine-grained molybdenite (referred to as fine-grained molybdenum ore). The particle size of molybdenite in the ore is generally 0.010-0.10mm, and the occupancy rate of molybdenite in the -0.020mm particle size reaches 10.68. %.

[0059] Such as figure 1 Shown technological process, concrete technological parameter is:

[0060] (1) Grinding process: put the fine-grained molybdenum ore, 1000 g / t sodium sulfide regulator, and 800 g / t transformer oil into the ball mill, add water for wet grinding, control the grinding concentration to 65%, and grind fine The degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com