Three-dimensional layered graphite-phase nitrogen carbide/MOF composite material and preparation method thereof

A composite material and layered graphite technology, applied in the field of materials, can solve the problems of limiting the wide application of MOFs materials, poor dispersion in water, poor stability, etc., and achieve fast adsorption speed, good stability, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

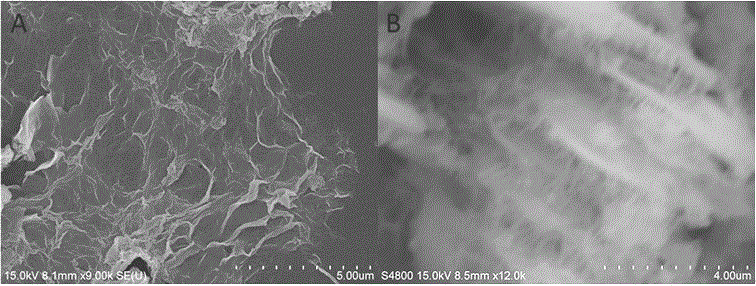

Image

Examples

Embodiment 1

[0024] A method for preparing a three-dimensional layered graphite phase nitrogen carbide / Cu-MOF composite material, comprising the steps of:

[0025] 1) g-C 3 N 4 Preparation of nanosheets

[0026] Spread 2 g of melamine powder on the bottom of a 50 mL crucible, close the lid tightly, transfer to a muffle furnace, raise the temperature to 550 °C at a rate of 2.3 °C / min and keep it for 4 h, then decrease to 550 °C at a rate of 2.3 °C / min. At room temperature, light yellow g-C 3 N 4 powder; then take 0.3g g-C 3 N 4 powder, add 200 mL deionized water, and after 150 W ultrasonic stripping for 6 h, the solution is centrifuged at 3000 rpm for 5 min to remove the unexfoliated solids in the lower layer, and the obtained supernatant is freeze-dried to obtain g-C 3 N 4 Nanosheet solid;

[0027] 2) Three-dimensional g-C 3 N 4 Preparation of Cu-MOF composites

[0028] Dissolve 1.087 g of copper nitrate trihydrate in 15 mL of water and add 10 mg of g-C 3 N 4 nanosheet solid; ...

Embodiment 2

[0030] A method for preparing a three-dimensional layered graphite phase nitrogen carbide / Cu-MOF composite material, comprising the steps of:

[0031] 1) g-C 3 N 4 Preparation of nanosheets

[0032] Spread 2 g of melamine powder on the bottom of a 50 mL crucible, close the lid tightly, transfer to a muffle furnace, raise the temperature to 550 °C at a rate of 2.3 °C / min and keep it for 4 h, then decrease to 550 °C at a rate of 2.3 °C / min. At room temperature, light yellow g-C 3 N 4 powder; then take 0.3g g-C 3 N4 powder, add 200 mL of deionized water, 150 W ultrasonic stripping for 12 h, centrifuge the solution at 3000 rpm for 5 min, remove the unexfoliated solids in the lower layer, and freeze-dry the obtained supernatant to obtain g-C 3 N 4 Nanosheet solid;

[0033] 2) Three-dimensional g-C 3 N 4 Preparation of Cu-MOF composites

[0034] Dissolve 1.087 g of copper nitrate trihydrate in 15 mL of water and add 5 mg of g-C 3 N 4 nanosheet solid; in addition, 0.525 g...

Embodiment 3

[0036] A method for preparing a three-dimensional layered graphite phase nitrogen carbide / Cu-MOF composite material, comprising the steps of:

[0037] 1) g-C 3 N 4 Preparation of nanosheets

[0038] Spread 2 g of melamine powder on the bottom of a 50 mL crucible, close the lid tightly, transfer to a muffle furnace, raise the temperature to 550 °C at a rate of 2.3 °C / min and keep it for 4 h, then decrease to 550 °C at a rate of 2.3 °C / min. At room temperature, light yellow g-C 3 N 4 powder; then take 0.3g g-C 3 N 4 powder, add 200 mL of deionized water, 150 W ultrasonic stripping for 24 h, centrifuge the solution at 3000 rpm for 5 min, remove the unexfoliated solids in the lower layer, and freeze-dry the obtained supernatant to obtain g-C 3 N 4 Nanosheet solid;

[0039] 2) Three-dimensional g-C 3 N 4 Preparation of Cu-MOF composites

[0040] Dissolve 1.087 g of copper nitrate trihydrate in 15 mL of water and add 15 mg of g-C 3 N 4 nanosheet solid; in addition, 0.52...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com