Preparation method of moso bamboo cellulose based nano oral drug carrier

A cellulose-based, cellulose-based technology that is applied in pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as not seen, reduce toxic side effects, and improve medication compliance Sex, the effect of expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

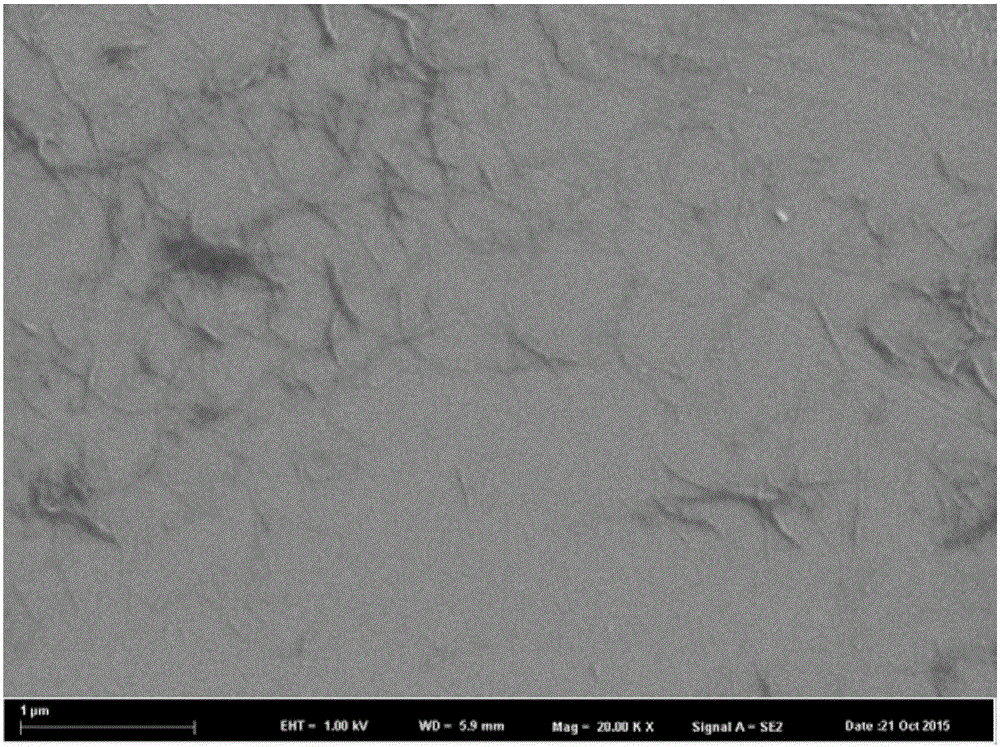

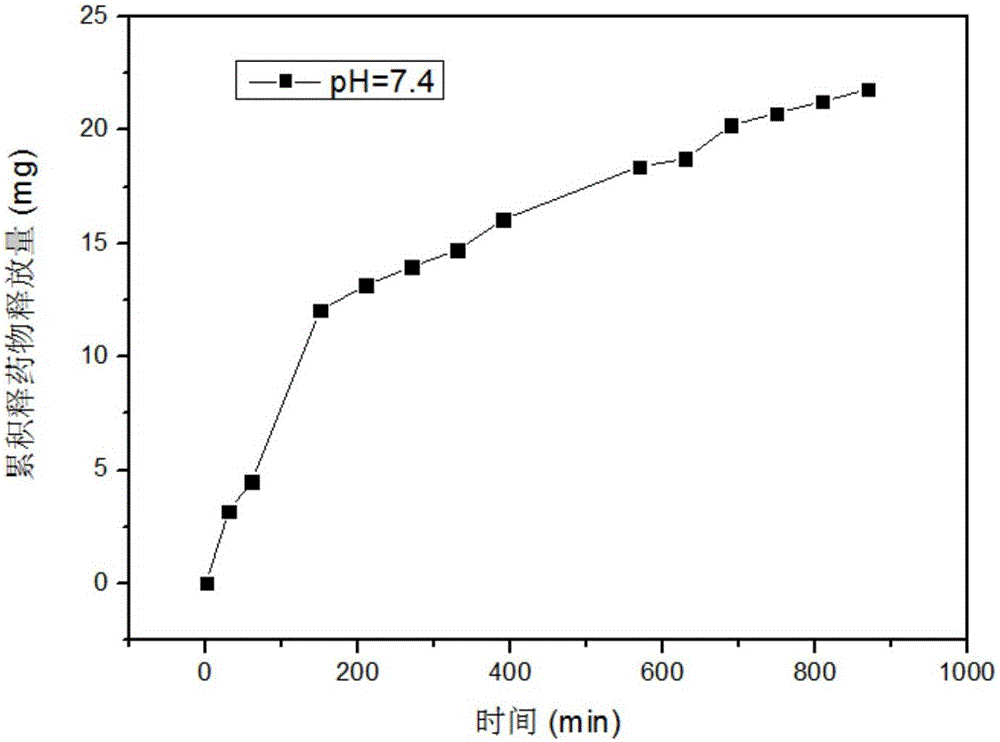

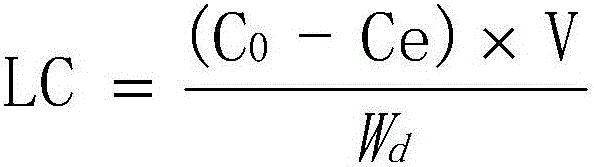

[0037] 1. Preparation of Moso bamboo cellulose-based nano-oral drug carrier

[0038] 1) After pulverizing the moso bamboo pulp board, filter it through a 100-mesh sieve to obtain moso bamboo pulp powder with a particle size less than or equal to 0.15 mm.

[0039] 2) Place the moso bamboo pulp powder obtained in step 1) at 45° C. and react in 60 wt % sulfuric acid solution for 180 min. The mass ratio of moso bamboo pulp powder to sulfuric acid solution is 1:15, and distilled water at room temperature with 10 times the volume of the above sulfuric acid solution is used Terminate the reaction, centrifuge and wash the residual acid with distilled water, and put the reacted mixture into a dialysis bag with a molecular weight cut-off of 120 kDa at room temperature, place it in distilled water and dialyze to neutrality, and freeze-dry to obtain the nanocrystalline cellulose of Moso bamboo.

[0040] 3) the bamboo nano-microcrystalline cellulose obtained in step 2) is dissolved in sodi...

Embodiment 2

[0046] 1. Preparation of Moso bamboo cellulose-based nano-oral drug carrier

[0047] 1) with embodiment 1.

[0048] 2) Place the moso bamboo pulp powder obtained in step 1) at 55° C. and react in 65 wt% sulfuric acid solution for 90 minutes. The mass ratio of moso bamboo pulp powder to sulfuric acid solution is 1:10, and distilled water at room temperature with 10 times the volume of the above sulfuric acid solution is used. Terminate the reaction, centrifuge and wash the residual acid with distilled water, and put the reacted mixture into a dialysis bag with a molecular weight cut-off of 130 kDa at room temperature, dialyze in distilled water until neutral, and freeze-dry to obtain Moso bamboo nanocrystalline cellulose.

[0049] 3) the bamboo nano-microcrystalline cellulose obtained in step 2) is dissolved in sodium hydroxide / urea solution, the mass fraction ratio of sodium hydroxide / urea solution is 6:4, and the moso bamboo nano-microcrystalline cellulose and sodium hydroxid...

Embodiment 3

[0055] 1. Preparation of Moso bamboo cellulose-based nano-oral drug carrier

[0056] 1) with embodiment 1.

[0057] 2) Place the moso bamboo pulp powder obtained in step 1) at 35°C and react in 55wt% sulfuric acid solution for 270min, the mass ratio of moso bamboo pulp powder to sulfuric acid solution is 1:20, and use room temperature distilled water with 10 times the volume of the above sulfuric acid solution Terminate the reaction, wash the residual acid by centrifugation with distilled water, and put the reacted mixture into a dialysis bag with a molecular weight cut-off of 140 kDa at room temperature, place it in distilled water and dialyze to neutrality, freeze-dry to obtain Moso bamboo nanocrystalline cellulose.

[0058] 3) the bamboo nano-microcrystalline cellulose obtained in step 2) is dissolved in sodium hydroxide / urea solution, the mass fraction ratio of sodium hydroxide / urea solution is 6:4, and the moso bamboo nano-microcrystalline cellulose and sodium hydroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com