Method for preparing temperature/pH sensitive hydrogel by using bamboo dissolving pulp

A sensitive hydrogel and dissolving slurry technology, applied in the field of hydrogel preparation, can solve the problems of expensive raw materials, environmental pollution, non-renewable, etc., and achieve the effect of solving non-renewable and expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

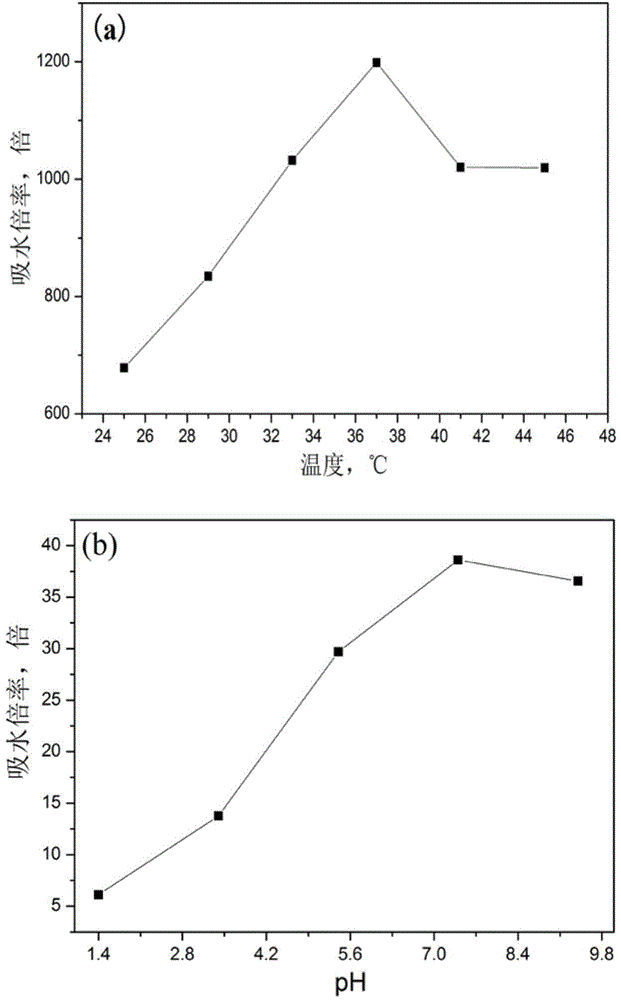

Image

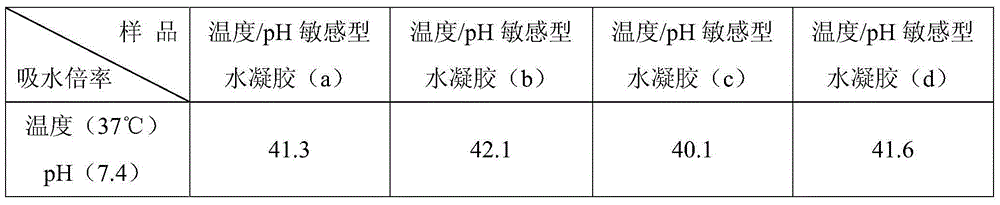

Examples

Embodiment 1

[0020] 1) Pulverizing the dissolving pulp of moso bamboo with a plant pulverizer, and filtering through a 100-mesh screen to obtain dissolving pulp powder of moso bamboo with a particle size less than or equal to 0.15mm;

[0021] 2) Add the moso bamboo dissolving pulp powder obtained in step 1) into -25°C precooled 5% sodium hydroxide and 13% urea mixed aqueous solution, the mass ratio of the sodium hydroxide and urea mixed aqueous solution to the moso bamboo dissolving pulp powder is 33 : 1, stirring at room temperature for 5min, freezing at -70°C for 90min, obtaining a uniform, transparent moso bamboo dissolving pulp cellulose solution;

[0022] 3) The cellulose solution of moso bamboo dissolving pulp in step 2) was passed through nitrogen for 30 minutes under 60°C water bath and mechanical stirring, 0.1g0.2g / mL ammonium persulfate was added, and 6g of acrylic acid, 2.5g of sodium hydroxide, 1.5 g acrylamide, 1.5g N-isopropylacrylamide and 0.04g0.02g / mLN,N'-methylenebisacryl...

Embodiment 2

[0024] 1) Pulverize the square bamboo dissolving pulp with a plant pulverizer, filter through a 100-mesh sieve, and obtain the square bamboo dissolving pulp powder with a particle diameter less than or equal to 0.15mm;

[0025] 2) The square bamboo dissolving pulp powder obtained in step 1) is added in -25 ℃ precooled 8% sodium hydroxide and 11% urea mixed aqueous solution, the mass ratio of sodium hydroxide and urea mixed aqueous solution and square bamboo dissolving pulp powder 35:1, stirred at room temperature for 5 minutes, and frozen at -70°C for 110 minutes to obtain a uniform and transparent square bamboo dissolving pulp cellulose solution;

[0026] 3) Put the bamboo dissolving pulp cellulose solution in step 2) in a 60°C water bath and under mechanical stirring for 40 minutes, add 0.2g of 0.3g / mL potassium persulfate, add 10g of acrylic acid, 2g of sodium hydroxide, 2g of Acrylamide, 1gN-isopropylacrylamide and 0.05g0.018g / mL polyethylene glycol acrylate were reacted f...

Embodiment 3

[0028] 1) Pulverizing the dissolving bamboo pulp with a plant pulverizer, filtering through a 100-mesh sieve to obtain dissolving bamboo pulp powder with a particle size of less than or equal to 0.15 mm;

[0029] 2) Add the dissolving bamboo pulp powder obtained in step 1) to -25°C precooled 9% sodium hydroxide and 9% urea mixed aqueous solution, the mass ratio of the mixed aqueous solution of sodium hydroxide and urea to the dissolving bamboo pulp powder 40:1, stirred at room temperature for 5 minutes, and frozen at -70°C for 100 minutes to obtain a uniform and transparent bamboo dissolving pulp cellulose solution;

[0030] 3) Put the bamboo dissolving pulp cellulose solution in step 2) in a 60°C water bath and under mechanical stirring for 60 minutes, add 0.3g of 0.1g / mL sodium persulfate, add 8g of acrylic acid, 2g of sodium hydroxide, 2.5 g of acrylamide, 0.5g of N-isopropylacrylamide and 0.08g of 0.01g / mL ethylene glycol dimethacrylate were reacted for 2 hours, taken out,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com