External resonator type light emitting device

A technology of external resonator and light-emitting device, which is applied in the structure, instrument, optics and other directions of optical resonator cavity, and can solve the problems of light intensity change and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

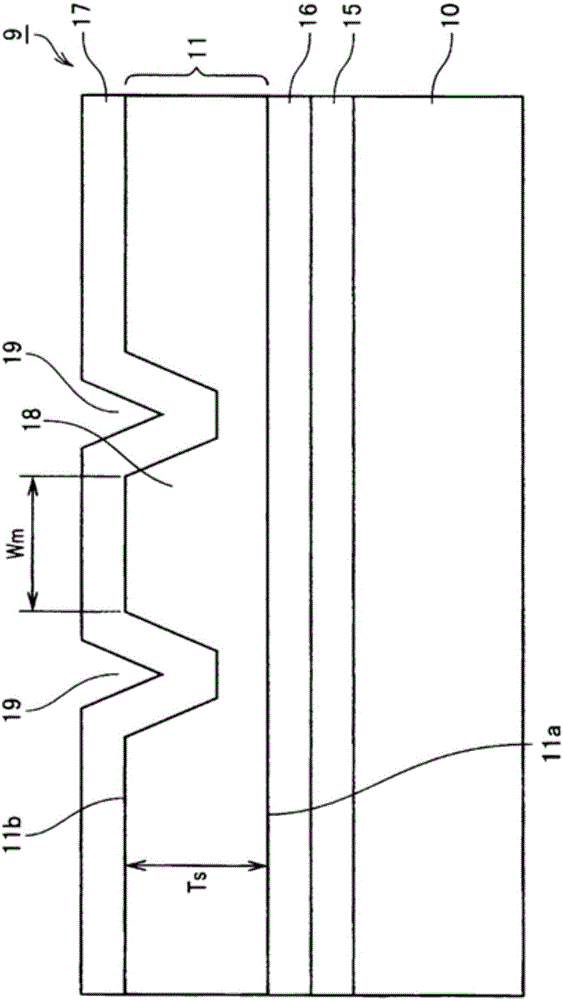

[0177] made as figure 2 , Figure 5 , Image 6 device shown.

[0178] Specifically, a Ti film was formed on a substrate obtained by z-cutting MgO-doped lithium niobate crystals, and a grating pattern was formed in the y-axis direction by photolithography. After that, fluorine-based reactive ion etching is performed using the Ti pattern as a mask, thereby forming b 100μm grating groove. The groove depth of the grating is 40nm. In addition, in order to form an optical waveguide propagating in the y-axis, a dry etching process is performed using a reactive ion etching device (RIE) to form a ridge-shaped trench.

[0179] Here, let the optical waveguide width W at the Bragg grating 12 m 3μm, height T r 0.5 μm. At the same time, if figure 2 As shown, a connection portion 20a with a constant width, a tapered portion 20b and an emission portion 20c with a constant width are provided. The dimensions of each part are as follows.

[0180] Optical waveguide width W at the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com