High-reliability pressure-adjusting automatic testing apparatus for fingerprint module group

A technology of automatic test device and fingerprint module, which is used in environmental/reliability testing, measuring device, measuring electricity, etc., can solve the problem of unstable force exerted on the surface of the product, affecting the reliability of product testing, and limited adjustable range and other problems to achieve consistent test results, save manpower, and improve productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

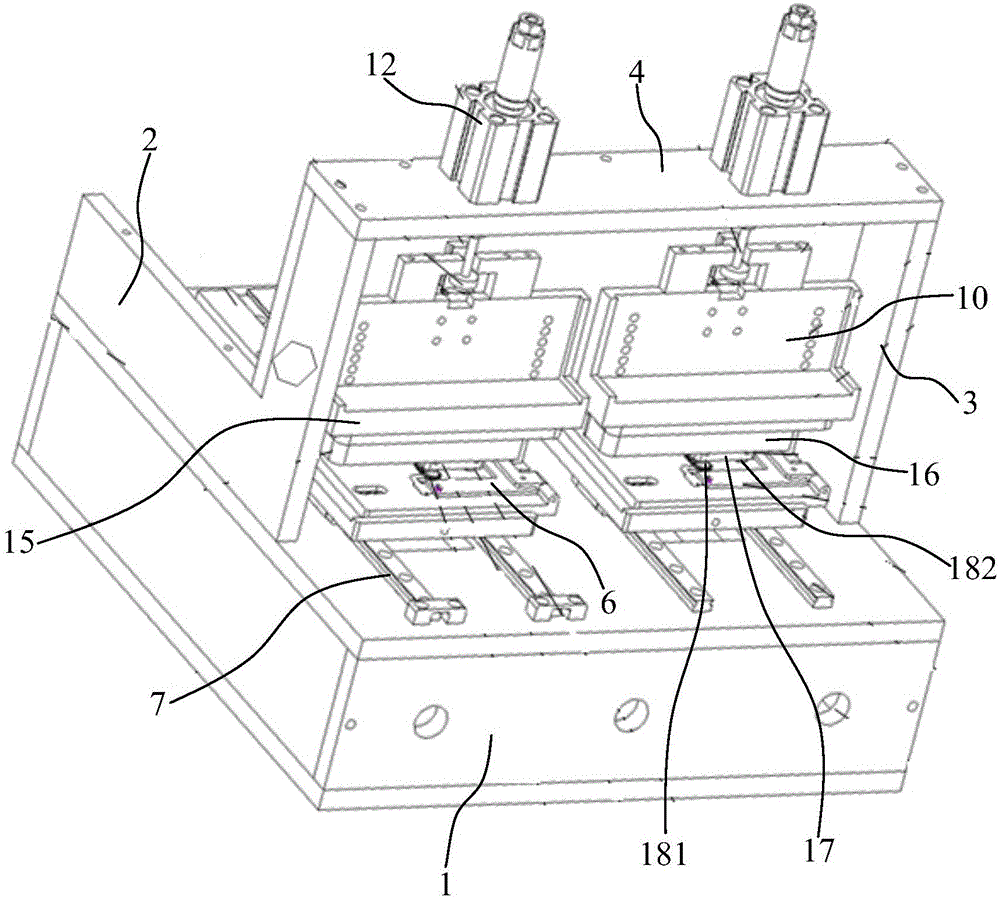

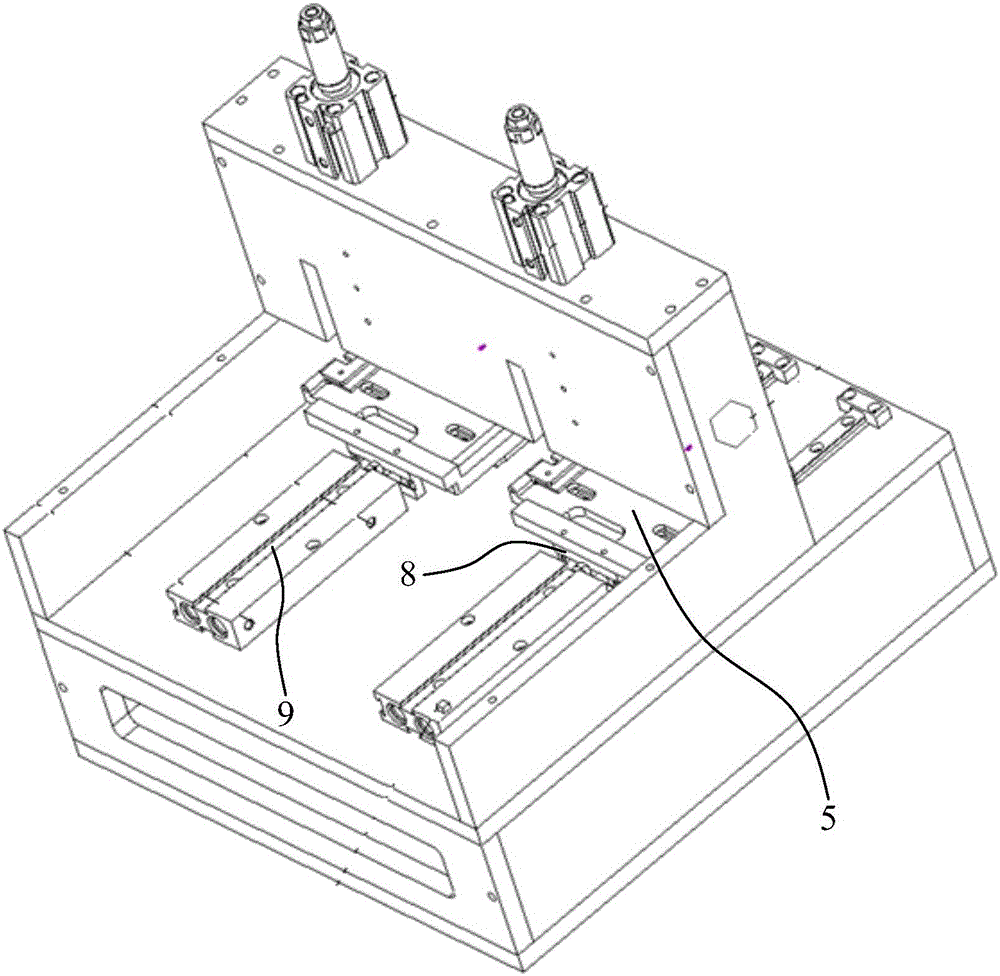

[0020] Embodiment 1: A highly reliable pressure-adjustable automatic testing device for a fingerprint module, comprising a base 1, a left support plate 2, a right support plate 3, a horizontal bridge plate 4, at least one horizontal stage 5 and an installation On the adapter plate 6 on the horizontal stage 5, the left support plate 2 and the right support plate 3 are installed on the left and right sides of the base 1, and the respective upper ends of the left support plate 2 and the right support plate 3 The horizontal bridge plate 4 is fixed therebetween;

[0021] Two x-direction rails 7 are arranged in parallel on the surface of the base 1, and at least two x-direction sliders 8 are fixed on the lower surface of the horizontal stage 5 in parallel, and the x-direction rails 7 are embedded in the x-direction slide In the groove of the block 8, an x-direction drive mechanism 9 is located between the two x-direction rails 7 and below the horizontal stage 5;

[0022] At least o...

Embodiment 2

[0026] Embodiment 2: A highly reliable pressure-adjustable automatic testing device for a fingerprint module, comprising a base 1, a left support plate 2, a right support plate 3, a horizontal bridge plate 4, at least one horizontal stage 5 and an installation On the adapter plate 6 on the horizontal stage 5, the left support plate 2 and the right support plate 3 are installed on the left and right sides of the base 1, and the respective upper ends of the left support plate 2 and the right support plate 3 The horizontal bridge plate 4 is fixed therebetween;

[0027] Two x-direction rails 7 are arranged in parallel on the surface of the base 1, and at least two x-direction sliders 8 are fixed on the lower surface of the horizontal stage 5 in parallel, and the x-direction rails 7 are embedded in the x-direction slide In the groove of the block 8, an x-direction drive mechanism 9 is located between the two x-direction rails 7 and below the horizontal stage 5;

[0028] At least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com