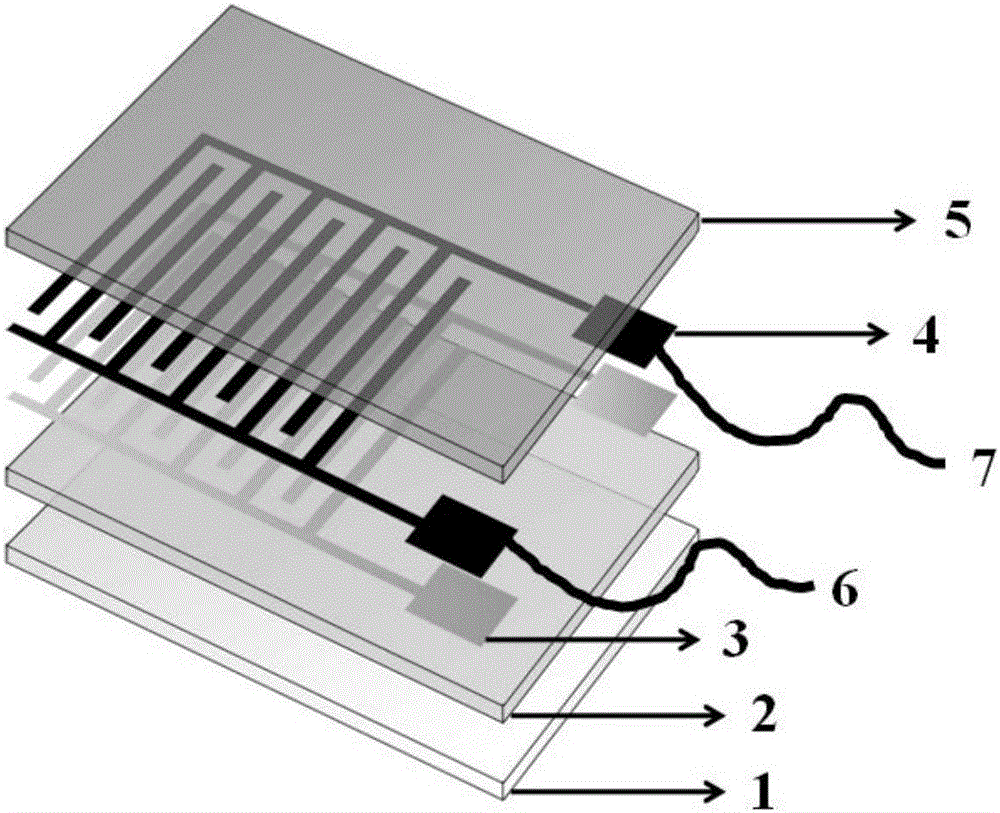

Resistance-type gas sensor based on graphene, stannic oxide and zinc oxide composite, preparation method and application thereof

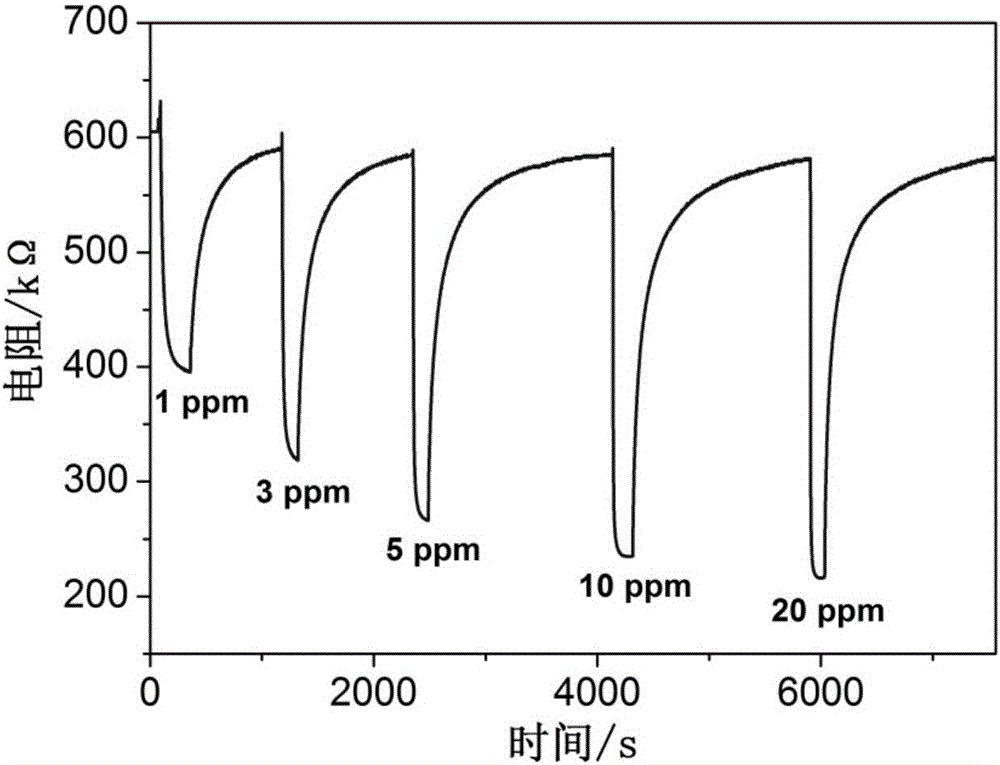

A gas sensor, tin dioxide technology, applied in nanotechnology for materials and surface science, material resistance, analytical materials, etc., can solve problems such as hindering application, slow response recovery, low sensitivity, etc., to achieve easy operation, improve The effect of adhesion and high response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031](1) Using single crystal silicon as the substrate, a silicon dioxide layer is formed on the surface of the single crystal silicon by thermal oxidation, with a thickness of 150nm, and a titanium adhesion layer is deposited on the surface of silicon dioxide by magnetron sputtering, with a thickness of 40nm ; Deposit a platinum metal layer on the surface of the titanium adhesion layer by magnetron sputtering, with a thickness of 50nm; spin-coat BP212 (Kempur Microelectronic INC) positive photoresist on the surface of the platinum metal, with a thickness of 1 μm; The same photoresist plate is placed on the photoresist surface, exposed to 350W ultraviolet light for 15 minutes, and then developed with a sodium hydroxide solution with a mass fraction of 5 / 1000, and the exposed photoresist is removed after development; Argon ions are used to bombard the surface of the platinum metal layer and the titanium adhesion layer, and the platinum metal layer and the titanium adhesion laye...

Embodiment 2

[0037] (1) With monocrystalline silicon as the substrate, a silicon dioxide layer is formed on the surface of the monocrystalline silicon by thermal oxidation method, with a thickness of 180nm, and a titanium adhesion layer is deposited on the surface of silicon dioxide by magnetron sputtering, with a thickness of 60nm ; Deposit a platinum metal layer on the surface of the titanium adhesion layer by magnetron sputtering, with a thickness of 100nm; spin-coat BP212 (Kempur Microelectronic INC) positive photoresist on the surface of the platinum metal, with a thickness of 1 μm; The same photoresist plate is placed on the photoresist surface, exposed to 350W ultraviolet light for 15 minutes, and then developed with a sodium hydroxide solution with a mass fraction of 5 / 1000, and the exposed photoresist is removed after development; then Argon ions are used to bombard the surface of the platinum metal layer and the titanium adhesion layer, and the platinum metal layer and the titaniu...

Embodiment 3

[0043] (1) Using single crystal silicon as the substrate, a silicon dioxide layer is formed on the surface of the single crystal silicon by thermal oxidation, with a thickness of 210nm, and a titanium adhesion layer is deposited on the surface of silicon dioxide by magnetron sputtering, with a thickness of 60nm ; Deposit a platinum metal layer on the surface of the titanium adhesion layer by magnetron sputtering, with a thickness of 100nm; spin-coat BP212 (Kempur Microelectronic INC) positive photoresist on the surface of the platinum metal, with a thickness of 1 μm; The same photoresist plate is placed on the photoresist surface, exposed to 350W ultraviolet light for 15 minutes, and then developed with a sodium hydroxide solution with a mass fraction of 5 / 1000, and the exposed photoresist is removed after development; then Argon ions are used to bombard the surface of the platinum metal layer and the titanium adhesion layer, and the platinum metal layer and the titanium adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com