Reciprocating type oblique impact slide tester

A reciprocating and tester technology, which is applied in the direction of instruments, measuring devices, and mechanical devices, can solve the problems of targeted evaluation, inability to apply impact and tangential stress at the same time, and achieve accurate test conclusions and combined performance conclusions accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

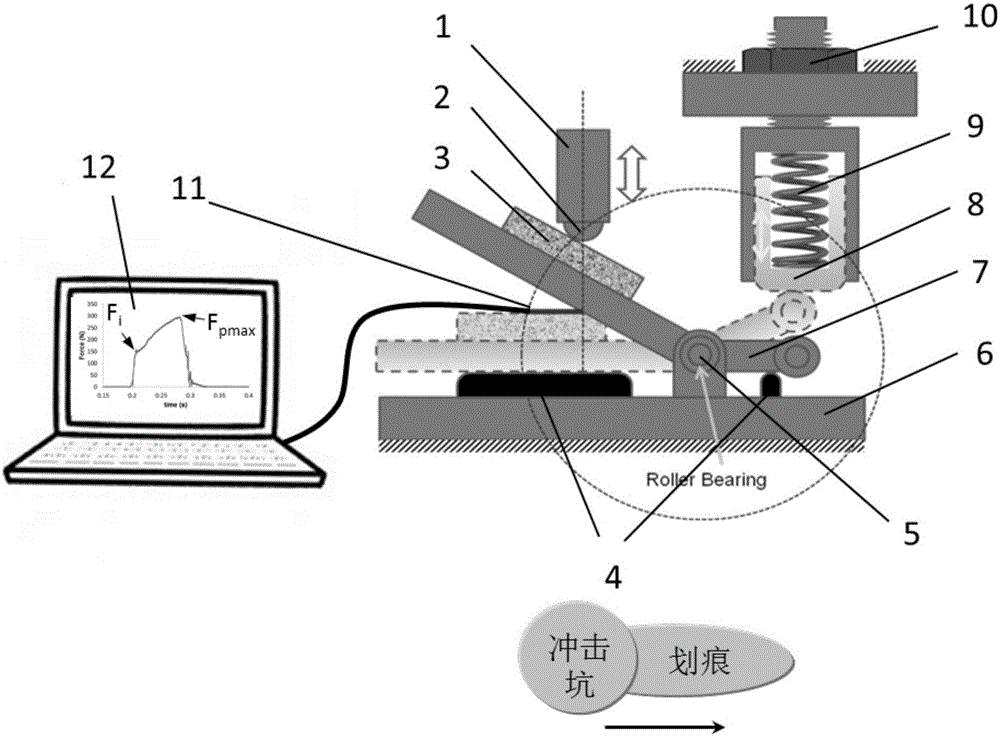

[0033] Such as figure 1 As shown, the reciprocating inclined impact slip tester includes a punch 2, a sample stage 3, a base 6 and a rocker 7, wherein,

[0034] The rocker 7 is bent, and the angle formed by bending the rocker 7 is 150°-160°, and the upper surfaces of the rocker 7 belong to two intersecting planes respectively; The rocker 7 is connected to the base 6 through a bearing, and the rocker 7 is used to rotate around the bearing to change the relative positional relationship between the rocker 7 and the base 6;

[0035] The sample stage 3 is arranged on the rocker 7, and is located on the upper surface of the rocker 7 belonging to one plane in the two intersecting planes; above the upper surface of the rocker 7 belonging to the other plane in the two intersecting planes A fixing mechanism is provided; the fixing mechanism is used to limit the rotation angle of the rocker 7 around the bearing, and is used to adjust the rotation angle of the rocker 7 around the bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com