Biomass double-crucible aluminum melting furnace

A biomass and aluminum melting furnace technology, applied in crucible furnaces, furnaces, furnace types and other directions, can solve problems such as increased energy consumption, affecting product quality, and increasing the difficulty of workers' operation, achieving low cost of use, avoiding manual scooping of aluminum, Make full use of the effect of thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

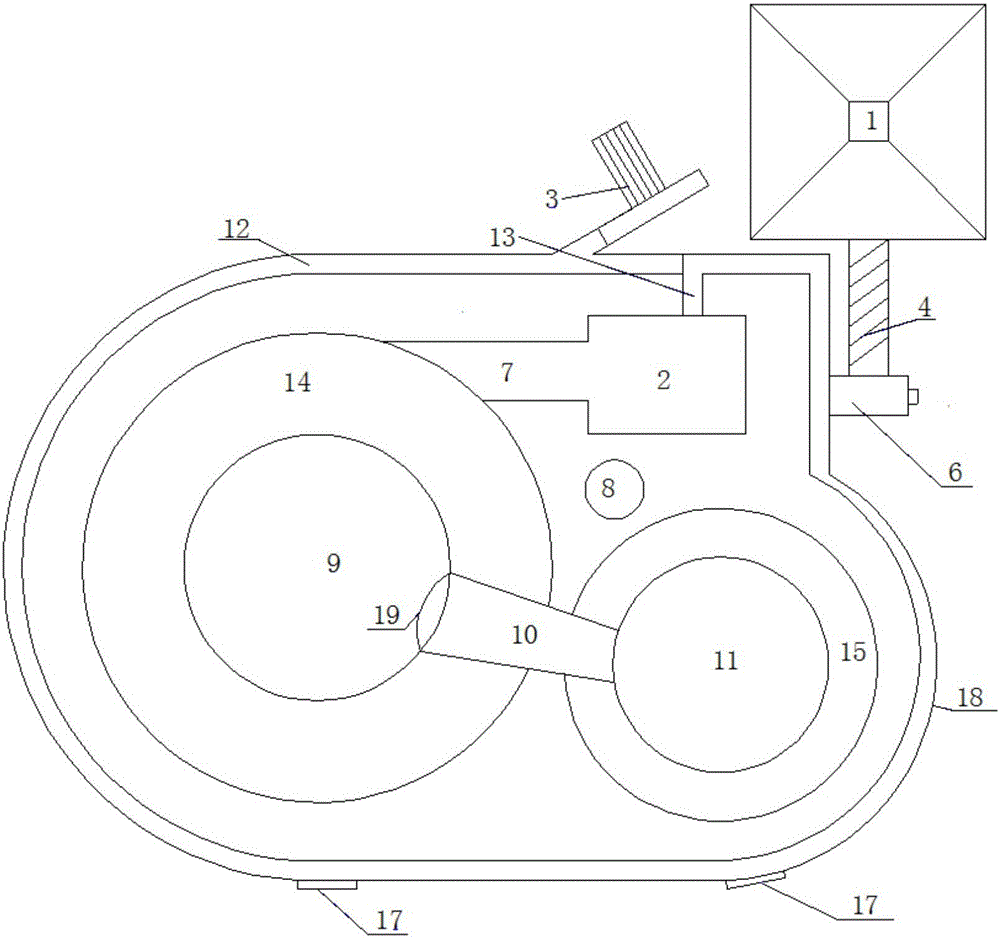

[0026] combine figure 1 , a biomass double-crucible aluminum melting furnace of the present embodiment, comprising a furnace shell 18, a biomass fuel bin 1 and a blower 3, the furnace shell 18 is provided with a furnace door 17, which is convenient for observing the situation in the furnace through the furnace door 17 A waste heat recovery cavity 12, a combustion air supply channel 13, a flame channel 7, a melting crucible heating channel 14, a heat preservation crucible heating channel 15 and a biomass combustion chamber 2 are formed in the furnace shell 18; the heat preservation refractory material is arranged in the waste heat recovery space Cavity 12, melting crucible heating channel 14, biomass combustion chamber 2 and heat preservation crucible heating channel 15;

[0027] The discharge port of the biomass fuel bin 1 is communicated with the feed port of the feeding pipe 6 through the feeding auger 4, and the discharge port of the feeding pipe 6 is communicated with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com