Soldering furnace waste heat treatment equipment based on convective heat exchange

A waste heat treatment and convection heat transfer technology, applied in waste heat treatment, welding equipment, lighting and heating equipment, etc., can solve the problems of difficult waste heat collection, heat energy waste, waste heat waste, etc., to improve the contact effect, improve the heat concentration effect, Improve the effect of heat concentrated heat dissipation and heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

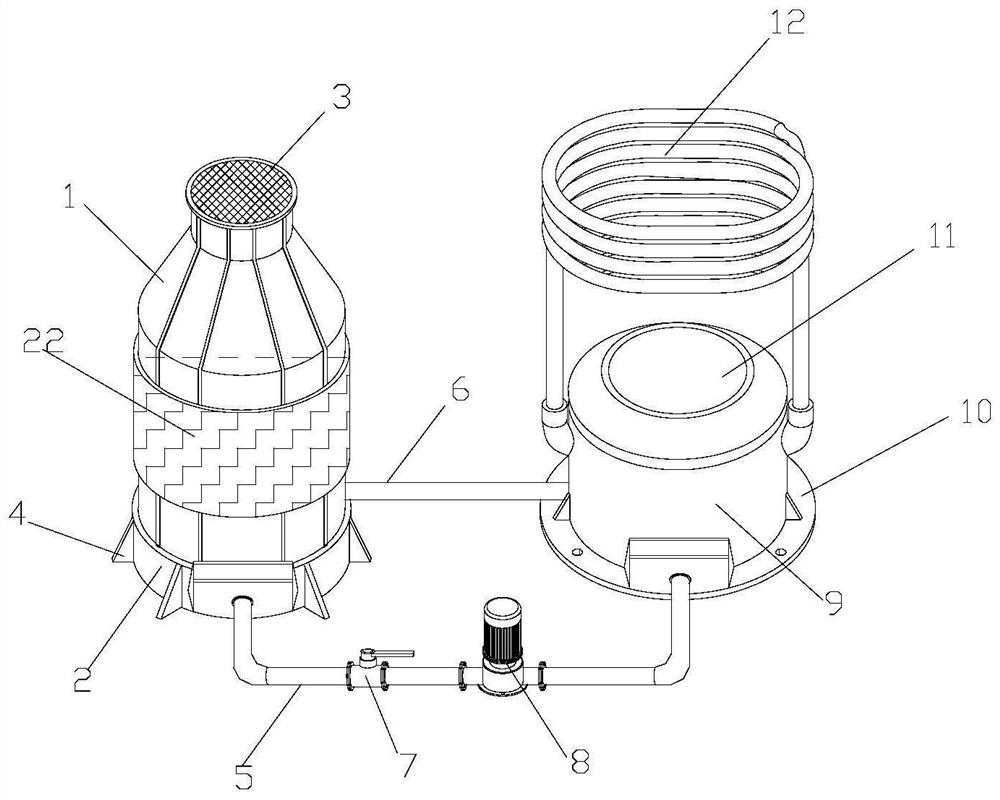

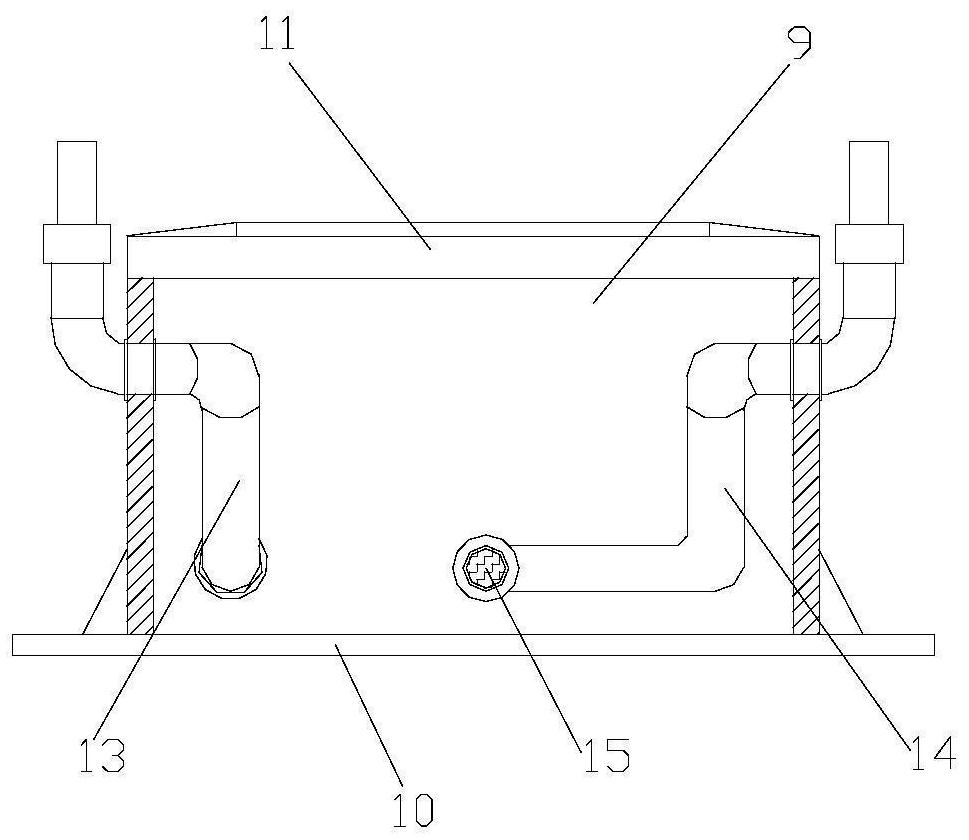

[0030] see Figure 1-8 , the present invention provides a soldering furnace waste heat treatment equipment based on convective heat exchange: including a closing tube 1, a bottom support 2, a dust-proof net 3, a reinforcing plate 4, a liquid delivery pipe 5, a liquid return pipe 6, a hand valve 7, and an oil pump 8. Oil guide chamber 9, bottom edge 10, top cover 11, heat exchange ring pipe 12, liquid inlet joint 13, liquid guide joint 14, heat conduction oil 15, cooling holes 16, liquid inlet pipe 17, heat delivery mechanism 18, delivery Heat ring pipe 19, heat storage mechanism 20, thermal detection probe 21 and heat insulation mechanism 22, bottom support 2 is welded at the bottom of closing tube 1, 3 circumferences of dust-proof net are fixedly installed on closing tube 1, and 2 circumferences of bottom support The reinforcement plate 4 is welded, the left ends of the liquid delivery pipe 5 and the liquid return pipe 6 are fixedly connected to the closing cylinder 1, the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com