Prefabricated Truss-Embedded Composite Beam

一种组合桁架、组合梁的技术,应用在组合梁领域,能够解决截面硬性弱、钢板单元火灾弱、难以期待现场施工操作性或节约工期等问题,达到韧性强、宽操作空间、节约搬运及保管费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the embodiments shown in the drawings. However, the shown embodiments are only illustrative for the convenience of understanding the present invention, and are not intended to limit the present invention.

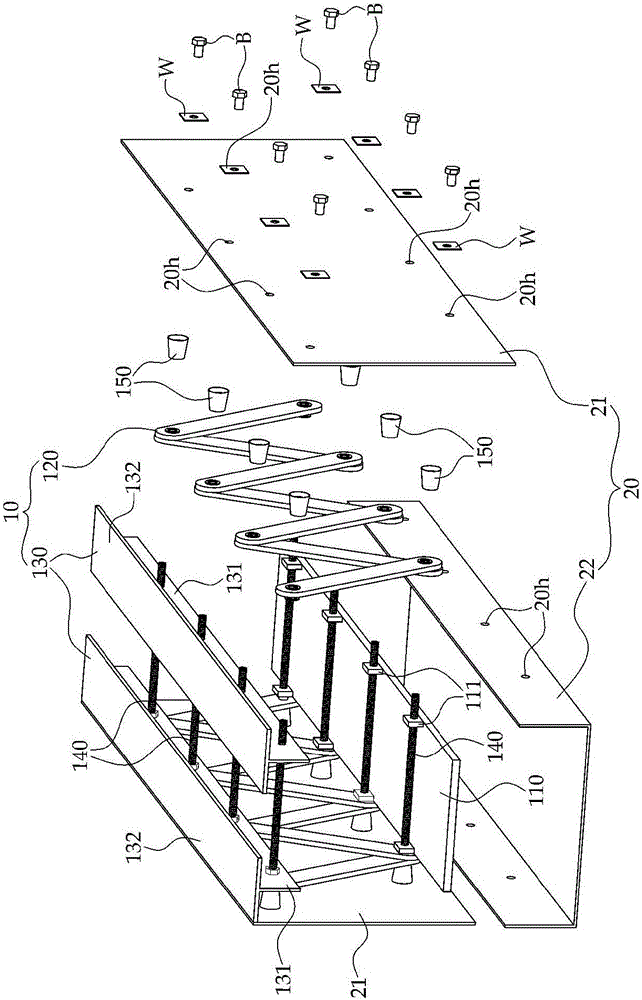

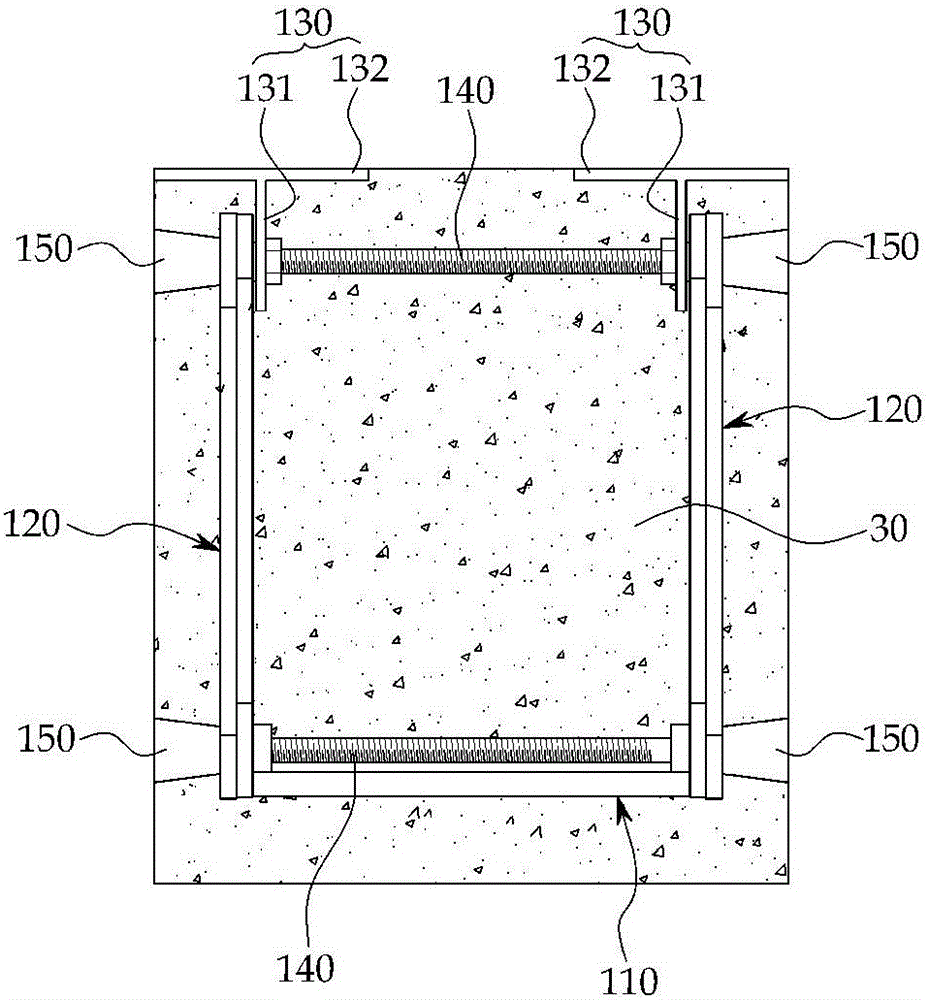

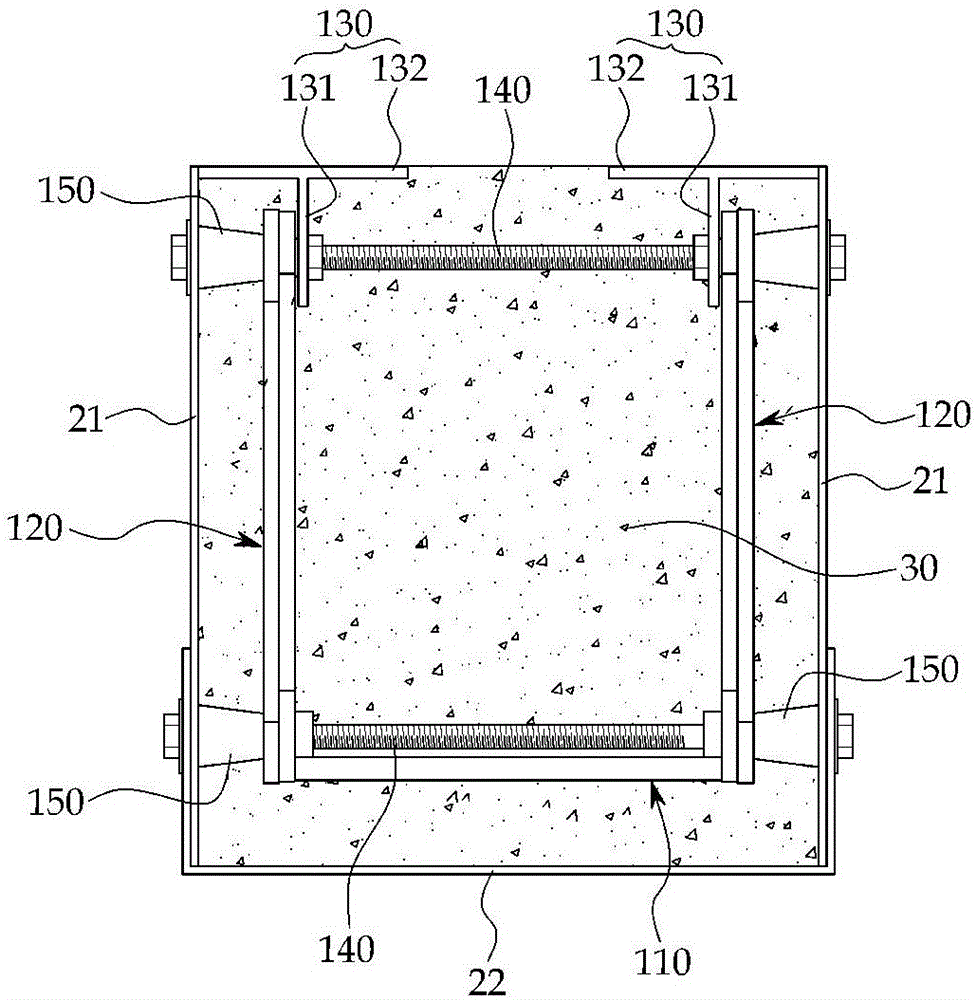

[0036] figure 1 It is an exploded perspective view of a composite truss embedded composite beam with a formwork attached according to an embodiment of the present invention, Figure 2a and 2b is a cross-sectional view.

[0037] The composite truss-embedded composite beam with formwork attached according to the present invention roughly includes a composite truss 10 , a formwork 20 and concrete 30 .

[0038]The composite truss 10 is composed of truss components including a lower suspension material, a composite material, and an upper suspension material. The lower suspension material 110 of the composite truss 10 according to the present invention is formed into a plate shape with a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com