Preparation method of W-plated diamond/aluminum composite

An aluminum composite material, diamond technology, applied in metal material coating process, sputtering plating, ion implantation plating and other directions, can solve the problems of poor interface bonding and low thermal conductivity of composite materials, and achieve good thermal conductivity, Improve thermal conductivity and thermal expansion coefficient matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode 1: The preparation method of W-coated diamond / aluminum composite material in this implementation mode:

[0021] 1. W plating on the surface of diamond particles:

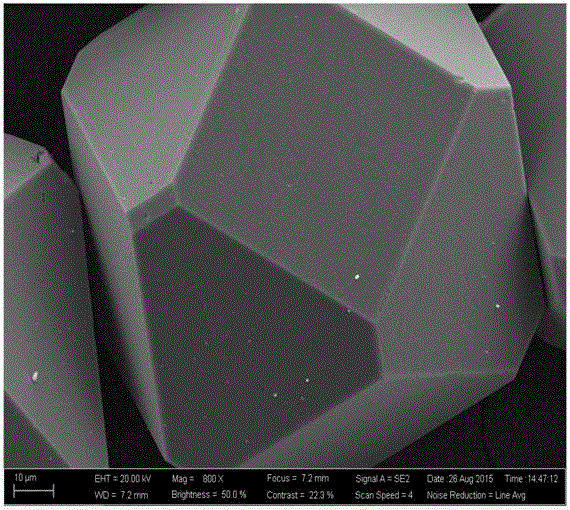

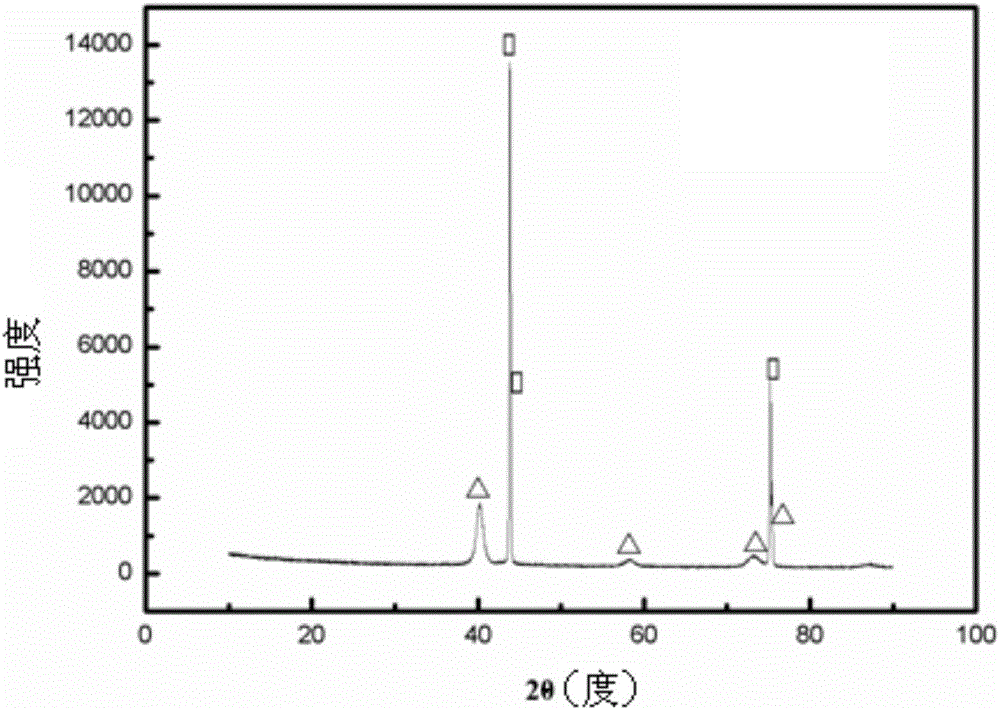

[0022] Using a tungsten target, the pretreated diamond particles were subjected to a magnetron sputtering pressure of 5×10 -3 ~9×10 -3 Pa, the sputtering voltage is 600V, the sputtering current is 0.9A, and the sputtering temperature is 300°C, sputtering for 90-360min to obtain W-coated diamond particles with a W coating thickness of 50-200nm;

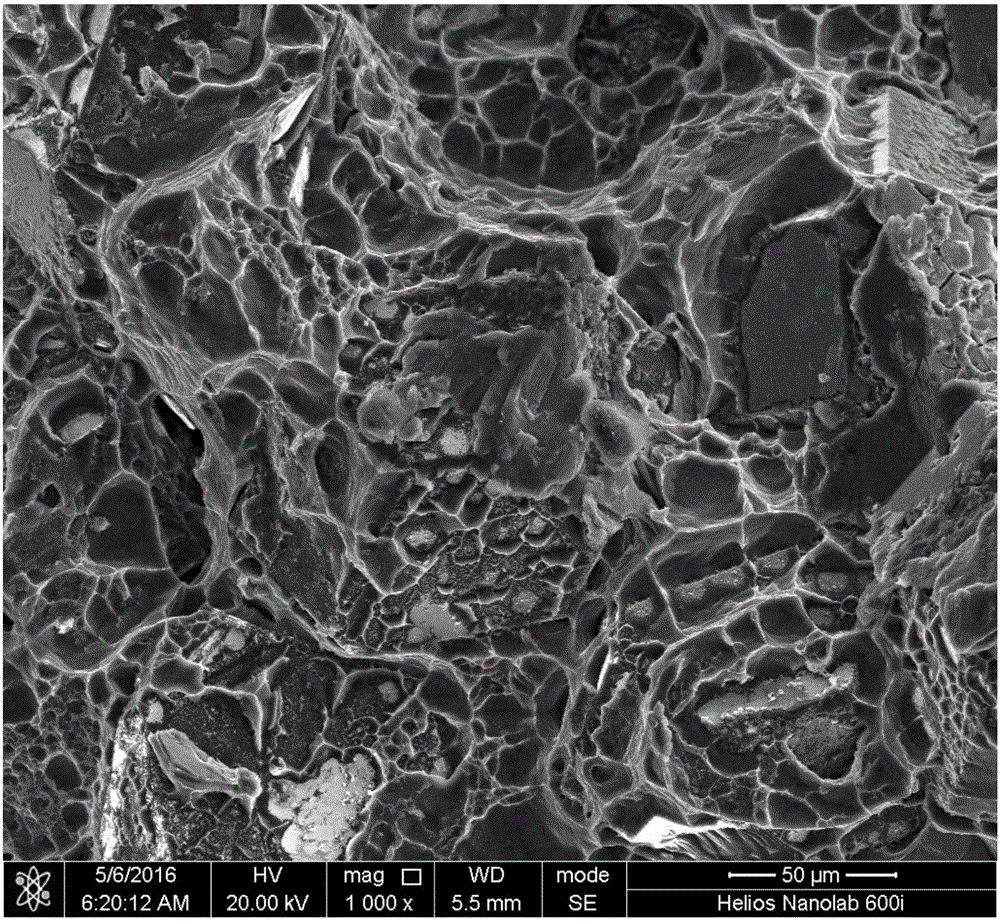

[0023] 2. Preheating: Fill the mold with W-coated diamond particles, place the pure aluminum ingot in the crucible, place the mold and the crucible with the pure aluminum ingot in the vacuum furnace, and vacuum at a speed of 25°C / min Raise the temperature to 500°C, keep it warm for 20 minutes, then raise the temperature to 700°C within 10 minutes, melt the pure aluminum ingot in the crucible and pour it into a mold filled with W-coated d...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the tungsten target described in Step 1 is a circular tungsten target with a purity of 99.99%, a diameter of 100 mm, and a thickness of 50 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the diamond particles described in Step 1 are MBD4, with a particle size of 100-200 μm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com