Graphene reinforced copper-based composite material and preparation method thereof

A copper-based composite material and graphene technology are applied in graphene-reinforced copper-based composite materials and their preparation, and in the field of copper-based composite materials. Serious damage, good enhancement effect, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

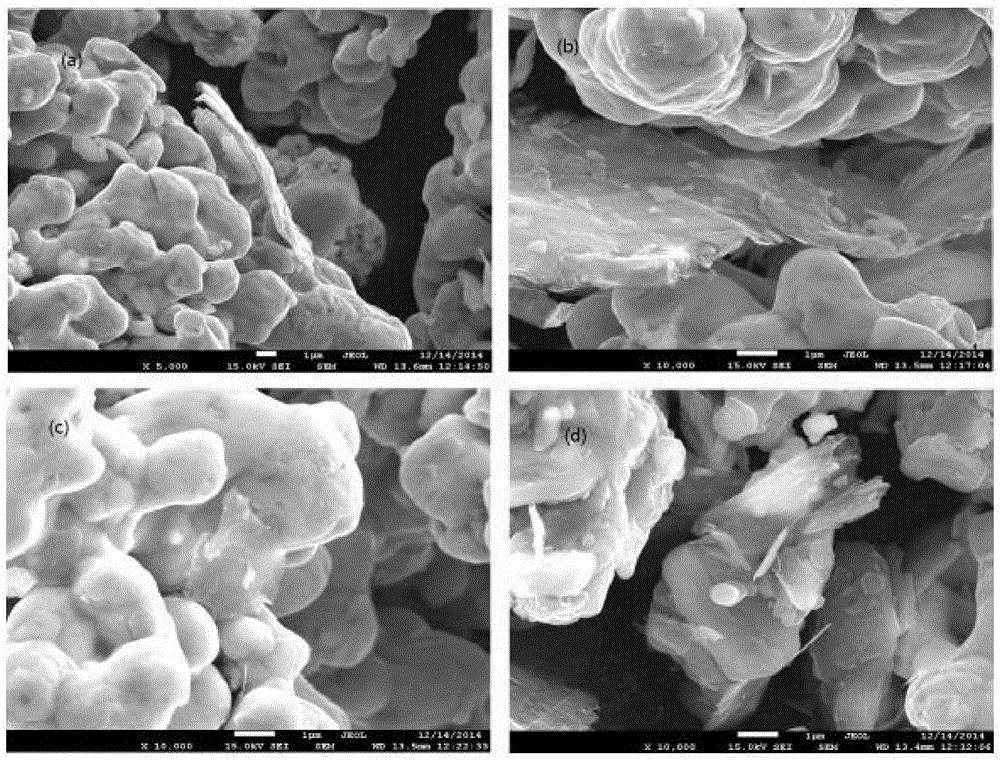

[0046] Add few-layer graphene to 10mg / mL gallic acid aqueous solution, and disperse evenly, wherein the ratio of the weight of graphene to the volume of gallic acid aqueous solution is 0.1g: 40mL; let it stand for 24h, filter, and take the filter residue at 60°C After vacuum drying for 2 h, the surface-modified graphene was obtained.

[0047] 0.1 g of the surface-modified graphene prepared in this example 1 was evenly dispersed in 100 mL of deionized water, and after standing for 5 days, the precipitation gradually increased under the action of gravity, but the graphene remained in a dispersed state without agglomeration; At the same time, compared with unmodified graphene, precipitation occurred after standing for 1 day, and agglomeration occurred between graphenes, indicating that the surface-modified graphene prepared in Example 1 had excellent dispersibility.

[0048] The specific surface area of the few-layer graphene is 400-700m 2 / g, the thickness is 0.55~3.74nm, and...

Embodiment 2

[0050] Add few-layer graphene to 3mg / mL gallic acid aqueous solution, and disperse evenly, wherein the ratio of the weight of graphene to the volume of gallic acid aqueous solution is 0.5g: 60mL; let it stand for 12h, filter, and take the filter residue at 70°C After vacuum drying for 1 h, the surface-modified graphene was obtained.

[0051] 0.1 g of the surface-modified graphene prepared in this example was evenly dispersed in 100 mL of deionized water, and after standing for 3 days, the precipitation gradually increased under the action of gravity, but the graphenes remained dispersed and did not agglomerate. Show that the surface-modified graphene prepared in Example 2 has excellent dispersibility.

Embodiment 3

[0053] Add the few-layer graphene into the gallic acid aqueous solution (supersaturated solution) of 18mg / mL, disperse evenly, wherein the weight of graphene and the volume ratio of gallic acid aqueous solution are 0.05g: 20mL; Stand still for 30h, filter, take The filter residue was vacuum-dried at 80° C. for 3 h to obtain surface-modified graphene.

[0054] 0.1 g of the surface-modified graphene prepared in this example was evenly dispersed in 100 mL of deionized water, and after standing for 2 days, the precipitation gradually increased under the action of gravity, but the graphenes remained dispersed and did not agglomerate. Show that the surface-modified graphene prepared in Example 2 has excellent dispersibility.

[0055] Comparing Examples 1 to 3, it can be seen that the surface-modified graphene prepared in Example 1 gradually precipitates under the action of gravity after standing for 5 days, and the graphenes are still well dispersed without agglomeration. However, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com