Method for preparing porous zirconium/aluminum tungstate composite material by spark plasma sintering

A technology of discharge plasma and aluminum composite material, which is applied in the field of preparation of porous zirconium tungstate/aluminum composite material, can solve the problems of fluctuation of thermal expansion curve and high thermal expansion value, and achieves reduction of thermal mismatch force, reduction of γ-phase generation and guarantee The effect of crystal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

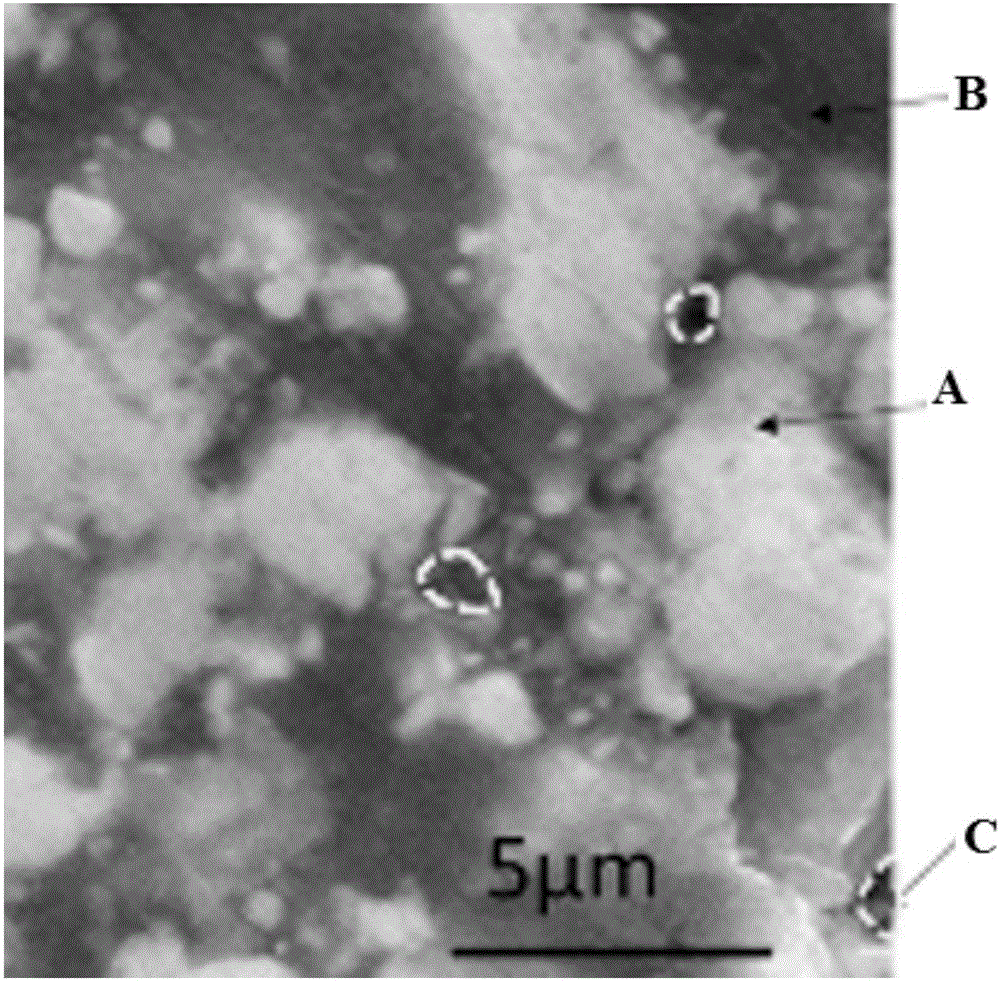

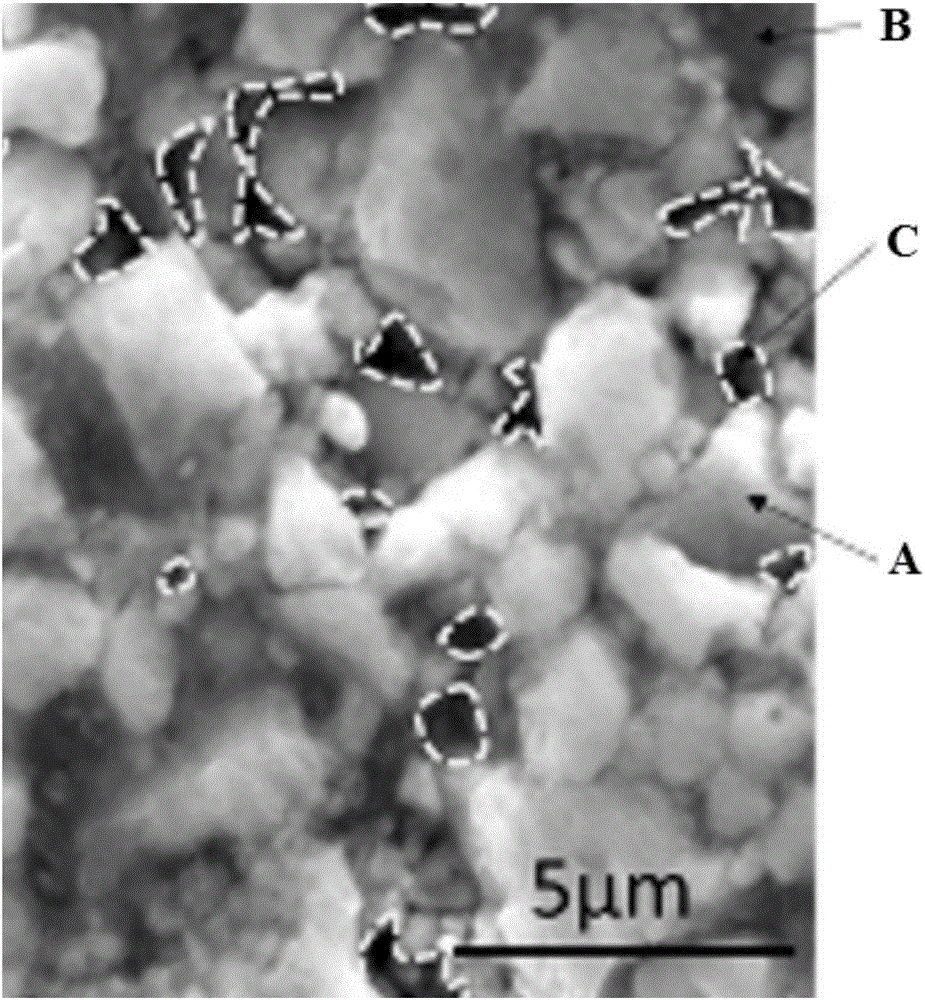

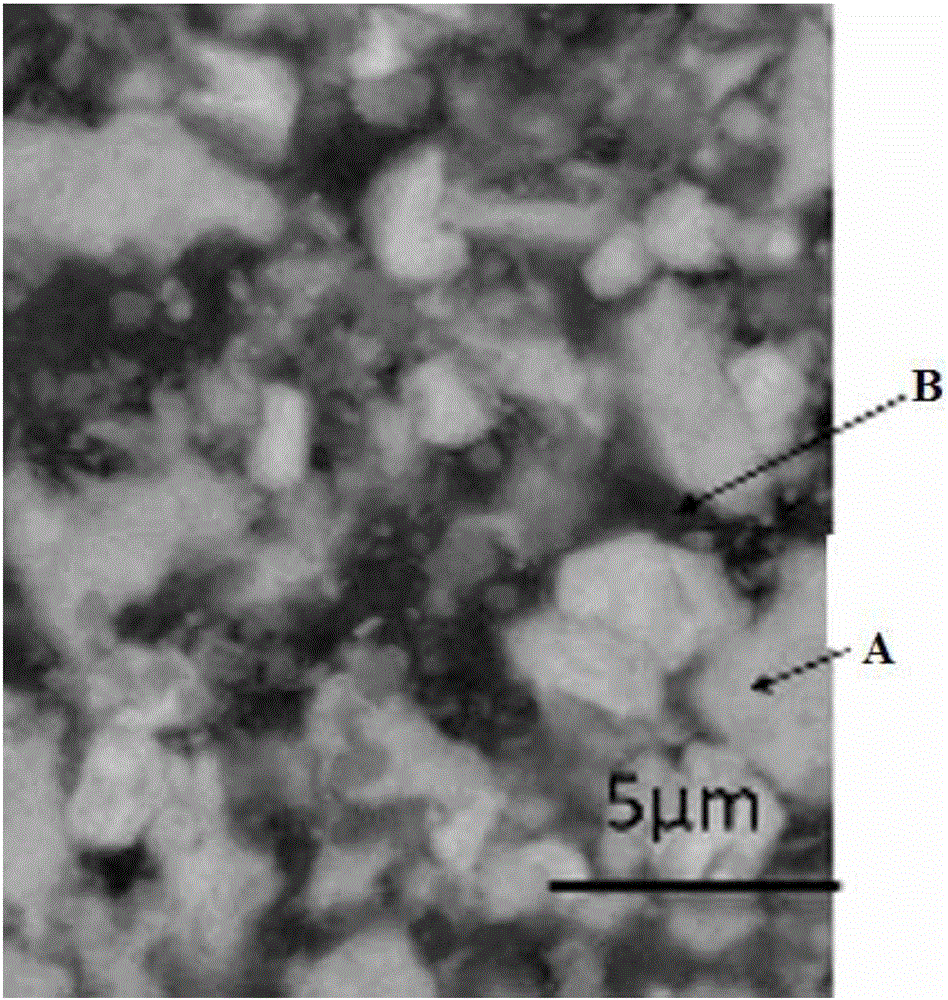

[0025] Specific implementation mode 1: This implementation mode is a method for preparing porous zirconium tungstate / aluminum composite material by spark plasma sintering, which is specifically completed according to the following steps:

[0026] 1. Weighing: Weigh 50-60% zirconium tungstate powder and 40-50% aluminum powder according to the volume fraction;

[0027] 2. Ball mill mixing: Add the zirconium tungstate powder and aluminum powder weighed in step 1 into the polyethylene ball mill tank in turn, then add agate balls, the ball-to-material ratio is 1:(1.2~1.5), and finally add absolute ethanol. The volume ratio of the zirconium tungstate powder and dehydrated alcohol is 1:(1.5~2), and the sealed ball mill is mixed for 12h~24h to obtain the mixed material after the ball mill;

[0028] 3. Drying and sieving: the mixed material after ball milling is dried and sieved to obtain mixed powder;

[0029] 4. Spark plasma sintering: Put the mixed powder into the graphite mold, th...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the purity of the zirconium tungstate powder described in step 1 is higher than 95%. Others are the same as the first embodiment. Others are the same as the specific embodiments 1 to 3.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the purity of the aluminum powder in step 1 is higher than 99%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com