Deep metamorphic clay type gold ore leaching method with high recycle rate

A high-recovery, clay-based technology, applied in the field of metallurgy and mineral processing, can solve the problems of large dosage of chemicals, thick clay layer, high surface energy, etc., and achieve the effects of comprehensive utilization of resources, reduced usage, and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

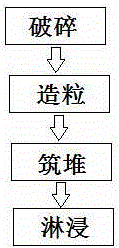

Method used

Image

Examples

Embodiment 1

[0033] The ore sample belongs to gold-bearing siliceous rock ore with severe weathering and metamorphism, the valuable component is only gold, the grade is 0.80g / t, and the main minerals are limonite, kaolinite, muscovite and quartz, etc. deal with:

[0034] Crush the raw ore and screen with a sieve to make all the ore crushed to 25 mm; divide the crushed raw ore into coarse-grained (+0.45 mm) and fine-grained (-0.45 mm); add 6000 g / t of lime To -0.45mm fine-grained grade, mix well; add 10% fine wood chips by volume to fine-grained grade; add 10% cement by volume to fine-grained grade, and then use granulator to granulate, Ensure that the compressive strength of a single ball is only about 1000N; the coarse-grained ore is piled at the bottom, and the pellets made of the fine-grained grade are placed on the upper part of the coarse-grained grade for heaping; when building the heap, it is pre-buried on the top of the ore heap Dripper. The pellets are piled up, and then cyanide...

Embodiment 2

[0036] The ore sample belongs to heavily weathered quartz feldspar complex vein gold-bearing ore, the valuable component is only gold, the grade is 1.3g / t, and the main minerals are quartz, plagioclase, limonite, muscovite, etc. The above raw ore is subjected to the following process steps deal with:

[0037] Crush the raw ore and screen with a sieve to make all the ore crushed to 20 mm; divide the crushed raw ore into coarse-grained (+0.45 mm) and fine-grained (-0.45 mm); add 5000 g / t of lime To -0.45 mm fine-grained grade, mix well; add 13% fine wood chips to the fine-grained grade; add 15% cement to the fine-grained grade, and then use a granulator to granulate to ensure its single ball The compressive strength is only about 1000N; the coarse-grained ore is piled at the bottom, and the pellets made of the fine-grained grade are placed on the upper part of the coarse-grained grade for heaping; the dripping pipe is pre-buried on the top of the ore heap when building the heap....

Embodiment 3

[0039] The ore sample belongs to the heavily weathered greenstone belt-type gold-bearing ore, the valuable component is only gold, the grade is 1.1g / t, and the main minerals are quartz, potassium feldspar, plagioclase, chlorite, sericite, etc. The following process steps are processed:

[0040] Crush the raw ore and screen with a sieve to make all the ore crushed to -18 mm; divide the crushed raw ore into coarse-grained (+0.45 mm) and fine-grained (-0.45 mm); add 5000 grams / ton of Lime to -0.45 mm fine-grained grade, and mixed; add 15% fine wood chips to the fine-grained grade; add 11% cement to the fine-grained grade, and then use a granulator to granulate to ensure its single The compressive strength of the ball is only about 1000N; the coarse-grained ore is piled at the bottom, and the pellets made of the fine-grained grade are placed on the upper part of the coarse-grained grade for heaping; the dripping pipe is pre-buried on the top of the ore heap when building the heap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com