Fine desulfurization method for liquid hydrocarbon

A technology of liquid hydrocarbon and hydrocarbon essence, which is applied in the treatment of hydrocarbon oil, multi-stage series refining process treatment, petroleum industry, etc., can solve the problem that the product quality requirements of liquid hydrocarbon sulfur content cannot be met, and the liquid hydrocarbon form sulfur cannot be effectively removed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

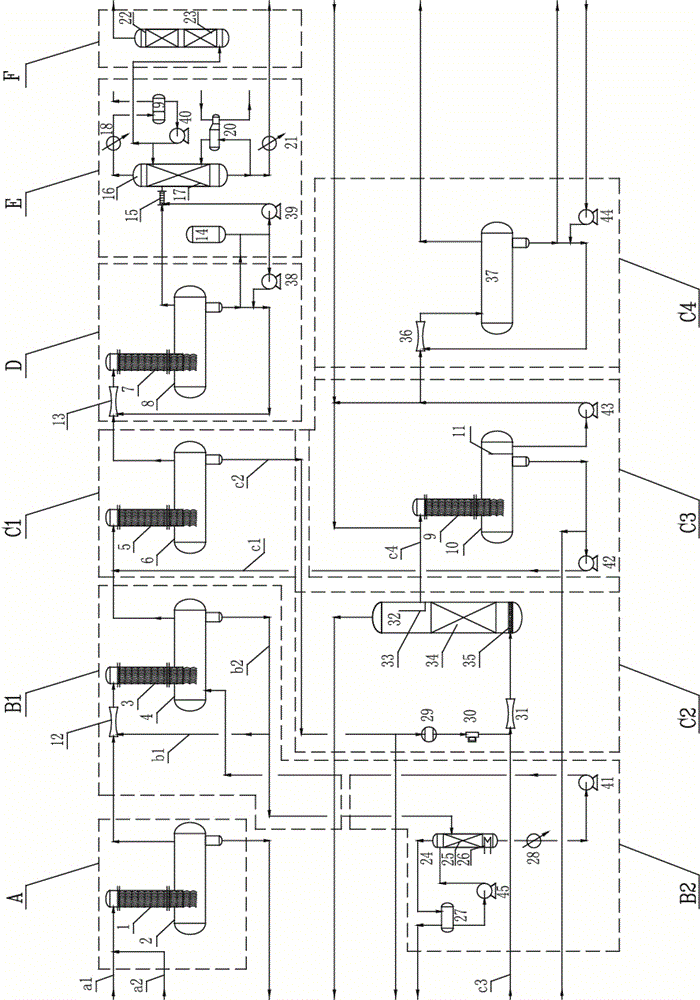

[0059] Example 1: The temperature of catalytic liquefied gas in a refinery is 30-40°C, the pressure is 2.4-2.5MPa, and the hydrogen sulfide content is 15000-30000mg / Nm 3 , mercaptan content 300-500mg / Nm 3 , carbonyl sulfide content 10-15mg / Nm 3 , disulfide content 5-10mg / Nm 3 , the total content of sulfur in other forms is 5-10mg / Nm 3 , requiring the total sulfur content of refined liquefied gas to be no more than 1mg / Nm 3 , the sodium ion content is less than 0.1ppm.

[0060] Use two-stage fiber liquid membrane contactor to elute hydrogen sulfide with amine, and the content of hydrogen sulfide in the liquefied gas after removal is less than 10mg / Nm 3 ; The carbonyl sulfide hydrolysis and hydrogen sulfide absorption unit B1 and carbonyl sulfide removal agent regeneration unit B2 of the first-stage fiber liquid membrane contactor are used. The regeneration flow rate of carbonyl sulfide rich removal agent is 15% of the circulation flow rate. The hydrogen sulfide content is ...

Embodiment 2

[0061] Example 2: The temperature of coking liquefied gas in a refinery is 30-45°C, the pressure is 1.4-1.6MPa, and the hydrogen sulfide content is 35000-60000mg / Nm 3 , mercaptan content 3000-6000mg / Nm 3 , carbonyl sulfide content 20-30mg / Nm 3 , disulfide content 50-80mg / Nm 3 , the total content of sulfur in other forms is 20-50mg / Nm 3 , it is required that the total sulfur content of refined liquefied gas shall not exceed 100mg / Nm 3 , Copper corrosion detection level 1, sodium ion content is less than 1ppm.

[0062] Use two-stage fiber liquid membrane contactor to elute hydrogen sulfide with amine, and the content of hydrogen sulfide in the liquefied gas after removal is less than 20mg / Nm 3 ; The carbonyl sulfide hydrolysis and hydrogen sulfide absorption unit B1 and the carbonyl sulfide removal agent regeneration unit B2 of the primary fiber liquid membrane contactor are used. The regeneration flow rate of the rich carbonyl sulfide removal agent is 20% of the circulation...

Embodiment 3

[0063] Example 3: After gas separation in a refinery, the carbon dioxide temperature is 50-60°C, the pressure is 0.5-0.6MPa, and the hydrogen sulfide content is less than 1mg / Nm 3 , mercaptan content 50-80mg / Nm 3 , carbonyl sulfide content is less than 1mg / Nm 3 , disulfide content 150-200mg / Nm 3 , the total content of sulfur in other forms is 30-50mg / Nm 3 , it is required that the total sulfur content of refined C4 should not exceed 5mg / Nm 3 , Copper corrosion detection level 1, sodium ion content is less than 1ppm.

[0064] Alkaline elution mercaptan unit C1, lye oxidation unit C2, lye back extraction unit C3 and solvent washing unit C4 using a primary fiber liquid membrane contactor. The temperature of the alkali solution in the tower is 40-50°C, the operating pressure of the oxidation tower is 0.2-0.3MPa, the total sulfur of gasoline fed into the device is less than 10ppm, the concentration of sodium mercaptide and disulfide in the regenerated alkali solution is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com