Method for preparing gemini surfactant by one-pot method

A technology of gemini surface and active agent, which is applied to the field of one-pot preparation of gemini surfactant, can solve the problems of large energy consumption, high cost, complicated reaction operation and the like, and achieves the effects of less usage, simple operation and simple reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

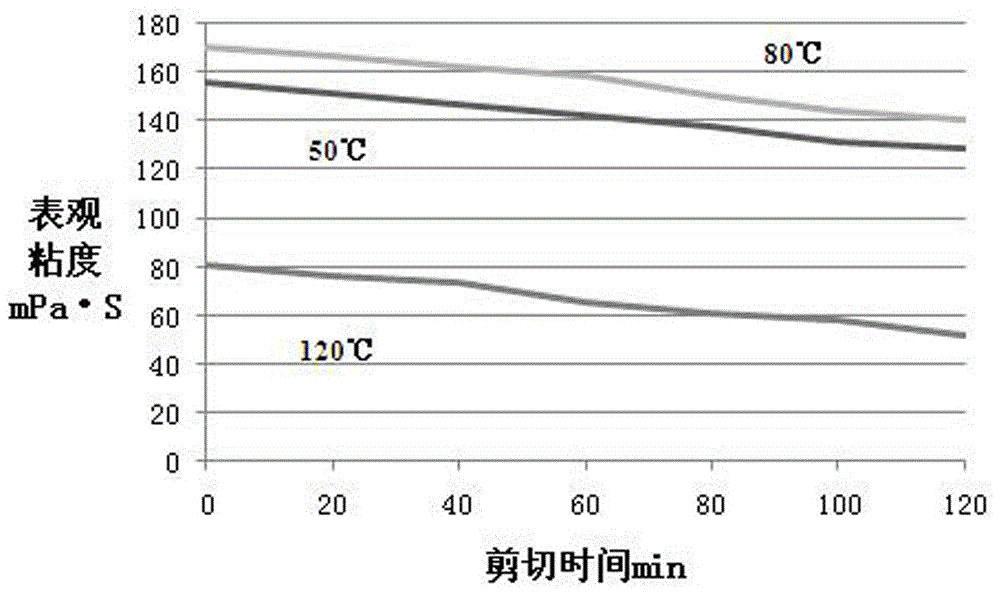

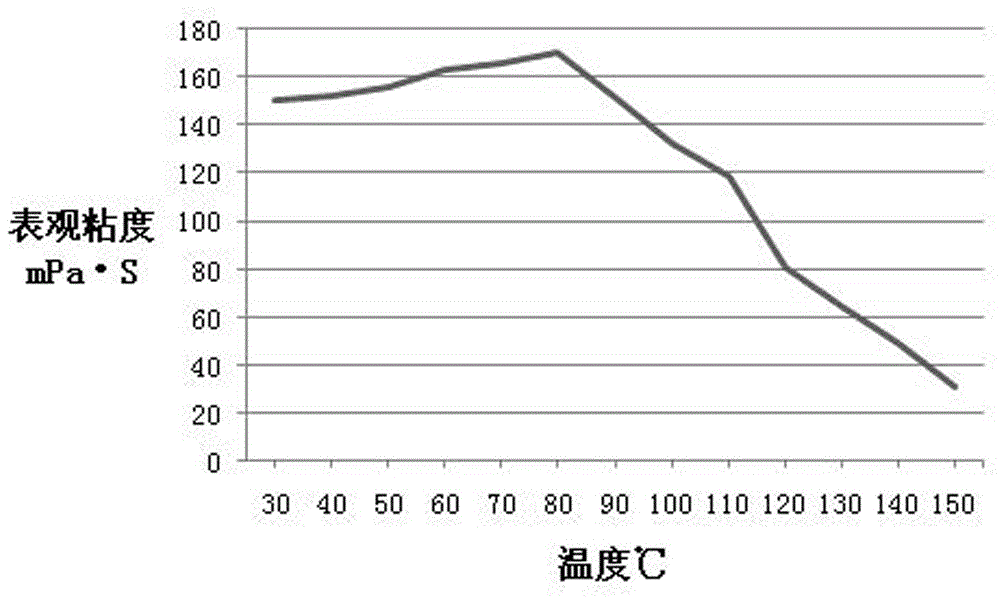

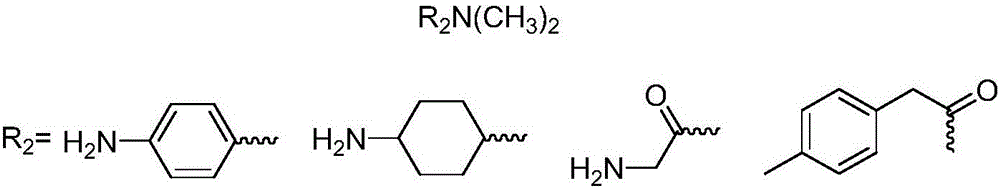

[0020] Molar ratio: stearic acid: oleic acid: 4-amino-N, N-dimethylaniline: [BMIM] BF 4 :1,3-dichloro-2-propanol=2:1:1.5:0.03:3, V 乙二醇 :V 丙二醇 =1:1, the quality of the solvent is 10% of the total mass of the reactants and the raw materials are prepared. In the reaction kettle equipped with electric stirrer, condenser, thermometer and oil bath heating condition, add stearic acid, oleic acid, 4-amino-N, N-dimethylaniline, l, 3-Dichloro-2-propanol, [BMIM]BF 4 , ethylene glycol, propylene glycol, stir and heat up to 50°C, keep the temperature for 1 hour; stir to 70°C, keep the temperature for 6 hours; stir and heat up to 110°C, keep the temperature for 8 hours; cool to room temperature, the obtained reddish brown The liquid is the gemini surfactant of the present invention.

[0021] The clean fracturing fluid Y1 can be obtained by mixing the Gemini surfactant into an aqueous solution with a mass concentration of 1% and an ammonium chloride solution with a mass concentration of ...

Embodiment 2

[0023] Molar ratio: stearic acid: erucic acid: 2-amino-N,N-dimethylacetamide: [BMIM]OH: 1,3-dibromo-2-propanol=2:1.5:2:0.035 :3,V 丁二醇 :V 丙三醇 =1:1.5, the amount of solvent added is 20% of the total mass and the raw materials are prepared. Have your ingredients ready. In a reaction kettle equipped with an electric stirrer, a condenser, a thermometer and heated by an oil bath, add stearic acid, erucic acid, 2-amino-N,N-dimethylacetamide, l , 3-dichloro-2-propanol, [BMIM]OH, glycerin, butanediol, stir and heat up to 60°C, keep the temperature for 1 hour; stir and heat up to 80°C, keep the temperature for 7 hours; stir and heat up To 120°C, keep the temperature and react for 9 hours; cool to room temperature, the obtained reddish-brown liquid is the gemini surfactant of the present invention.

[0024] The clean fracturing fluid Y2 can be obtained by mixing the gemini surfactant into an aqueous solution with a mass concentration of 2% and an ammonium chloride solution with a mas...

Embodiment 3

[0026] Molar ratio: benzenesulfonic acid: oleic acid: 4-methyl-N,N-dimethylphenylacetamide: [HDBU]PF 6 :1,3-dibromo-2-propanol=1:2:2:0.03:3, V 乙二醇 :V 丁二醇 =1.2:1, the amount of solvent added is 10% of the total mass and the raw materials are prepared. Add benzenesulfonic acid, oleic acid, and 4-methyl-N,N-dimethylphenylacetamide in the above molar proportions to the reaction kettle equipped with electric stirrer, condenser, thermometer and oil bath , 1,3-dichloro-2-propanol, [HDBU]PF 6 , ethylene glycol, butanediol, stirred and heated to 50°C, kept the temperature for 2 hours; stirred to 60°C, kept the temperature for 9 hours; stirred and heated to 120°C, kept the temperature for 10 hours; cooled to room temperature, obtained The reddish-brown liquid is the gemini surfactant of the present invention.

[0027] The clean fracturing fluid Y3 can be obtained by mixing the Gemini surfactant into an aqueous solution with a mass concentration of 3% and an ammonium chloride solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com