TPU (thermoplastic polyurethanes) film and preparation method thereof

A film, UV770 technology, applied in the field of TPU film and its preparation, can solve the problems of poor gas permeability of TPU film, can not be used as car seat cushions, etc., achieve the effect of small difference in mechanical properties, improved plasticizing effect, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

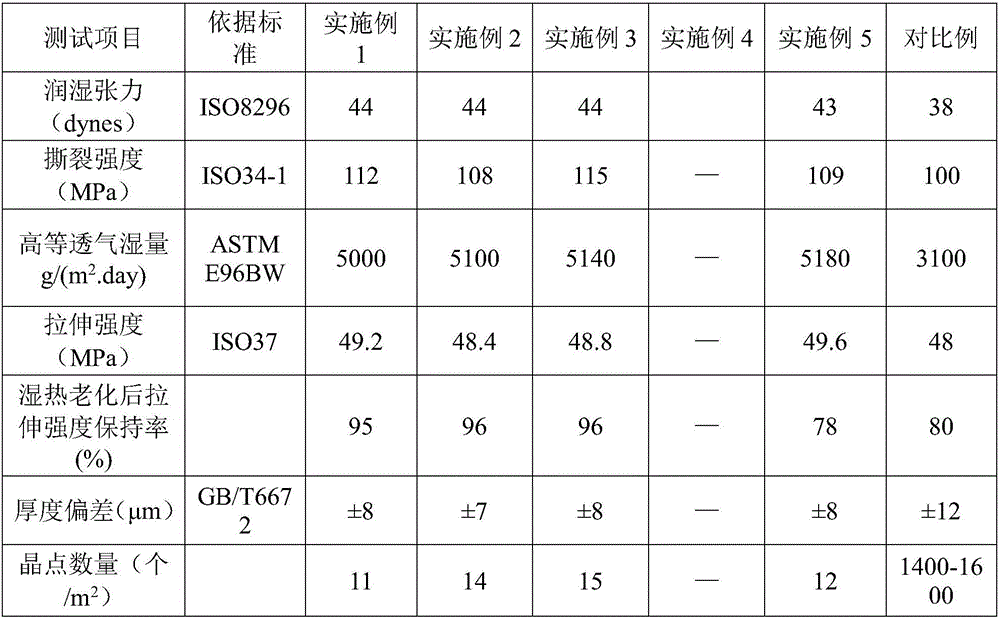

Examples

preparation example Construction

[0034] Correspondingly, the present invention also provides a kind of preparation method of TPU film, comprises the following steps:

[0035] (1) Crush TPU resin and PHA resin into 30-50 mesh powder at 10°C-15°C;

[0036] (2) 88-94 parts by weight powdered TPU resin, 4-8 parts by weight powdered PHA resin, 1-2 parts by weight anti-hydrolysis agent, 0.5-1 parts by weight light stabilizer, 0.5-1 parts by weight antioxidant Add to a high-speed mixer and mix well;

[0037] (3) The mixed material is plasticized by a planetary extruder, devolatilized, five-roll calendered, drawn off, embossed, and cooled to obtain a TPU film.

[0038] The temperature of the planetary extruder is: 120-145°C for the first stage and 150-155°C for the second stage.

[0039] The devolatilization device is installed in the second stage of the planetary extruder, which can effectively eliminate the volatile matter in the plasticizing process.

[0040] The five-roll calender adopts F-type five-roll calen...

Embodiment 1

[0051] Weigh various raw materials according to the ratio of mass and number stated below

[0052] 88 parts by weight of TPU resin, 8 parts by weight of PHA resin, 2 parts by weight of anti-hydrolysis polycarbodiimide, 1 part by weight of light stabilizer UV531, and 1 part by weight of antioxidant I1010.

[0053] Described a kind of TPU film preparation method is as follows:

[0054] (1) Crush TPU resin and PHA resin into 30-50 mesh powder at 10°C-15°C;

[0055] (2) 88 parts by weight of powdery TPU resin, 8 parts by weight of powdery PHA resin, 2 parts by weight of anti-hydrolysis agent, 1 part by weight

[0056] Parts by weight of light stabilizer and 1 part by weight of antioxidant are added to a high-speed mixer and mixed uniformly;

[0057] (3) The mixed material is plasticized by planetary extruder, devolatilized, five-roll calendered, drawn off, embossed and cooled to obtain TPU

[0058] film.

[0059] The temperature of the planetary extruder is: 120°C for the firs...

Embodiment 2

[0063] Weigh various raw materials according to the ratio of mass and number stated below

[0064] 94 parts by weight of TPU resin, 4 parts by weight of PHA resin, 1 part by weight of anti-hydrolysis agent polycarbodiimide, 0.5 part by weight of light stabilizer UV531, and 0.5 part by weight of antioxidant I1010.

[0065] Described a kind of TPU film preparation method is as follows:

[0066] (1) Crush TPU resin and PHA resin into 30-50 mesh powder at 10°C-15°C;

[0067] (2) 94 parts by weight of powdery TPU resin, 4 parts by weight of powdery PHA resin, 1 part by weight of anti-hydrolysis agent, 0.5 part by weight of light stabilizer, and 0.5 part by weight of antioxidant are added to a high-speed mixer and mixed uniformly;

[0068] (3) The mixed material is plasticized by a planetary extruder, devolatilized, five-roll calendered, drawn off, embossed, and cooled to obtain a TPU film.

[0069] The temperature of the planetary extruder is: 145°C for the first stage and 155°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com