A kind of graphene composite metal sheet and preparation method thereof

A graphene composite, graphene sheet technology, applied in metal layered products, chemical instruments and methods, layered products, etc., can solve problems such as environmental pollution, limited application, poor thermal conductivity, etc., and achieve the effect of reducing high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A graphene composite metal sheet and a preparation method thereof, which is composed of graphene sheets and metal sheets alternately laminated, firstly the graphene powder is processed to obtain modified graphene, and then obtained by melt extrusion Graphene sheet, and then the obtained graphene sheet and iron sheet of certain thickness can be obtained graphene composite metal sheet through calendering. The specific process steps are as follows:

[0020] (1) Preparation of graphene sheet: take 86-92 parts of graphene powder for automatic dehumidification, transport it to a high-low temperature blending kettle with an automatic metering and feeding system, and then add 3-8 parts of liquid silicone and 4- 6 parts of bismaleimide, blending and copolymerization at a low speed at 230 ° C, and then adding 0.02 to 0.1 parts of curing accelerator to adjust the polymerization, and then automatically convey the obtained modified graphene powder to the conical A twin-screw extrud...

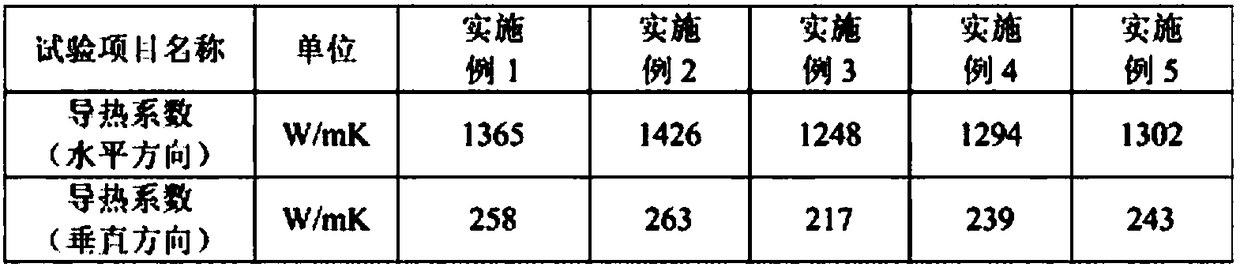

Embodiment 1

[0033] First, after automatic dehumidification of 90 parts of graphene powder, it is transported to a high-low temperature blending tank with an automatic metering and feeding system, and then 5.54 parts of side-containing hydrogen silicone oil and 4.4 parts of diphenylmethane bismaleimide are added. Perform low-speed blending and copolymerization at 230°C, then add 0.06 parts of 2-methylimidazole to adjust polymerization, and then automatically transport the obtained modified graphene powder to a conical twin-screw extruder for melt extrusion, Graphene sheets are obtained; then the preheated iron strips of a certain thickness and the graphene sheets are simultaneously conveyed to large heating calender rollers, the temperature is controlled at 260°C-280°C, and the graphene A layer of adhesive is applied on the surface of the iron sheet combined with the sheets. After the graphene sheet and the iron sheet are docked, the two are tightly rolled in the two-roll calendering, and t...

Embodiment 2

[0035] First, after automatic dehumidification of 92 parts of graphene powder, it is transported to a high-low temperature blending tank with an automatic metering and feeding system, and then 3.98 parts of side-containing hydrogen silicone oil and 4.0 parts of diphenylmethane bismaleimide are added, Perform low-speed blending and copolymerization at 230°C, then add 0.02 parts of 2-methylimidazole to adjust polymerization, and then automatically transport the obtained modified graphene powder to a conical twin-screw extruder for melt extrusion, Graphene sheets are obtained; then the preheated iron strips of a certain thickness and the graphene sheets are simultaneously conveyed to large heating calender rollers, the temperature is controlled at 260°C-280°C, and the graphene A layer of adhesive is applied on the surface of the iron sheet combined with the sheets. After the graphene sheet and the iron sheet are docked, the two are tightly rolled in the two-roll calendering, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com