Processing method of low sodium salt rapid-fermented pickled preserved meat

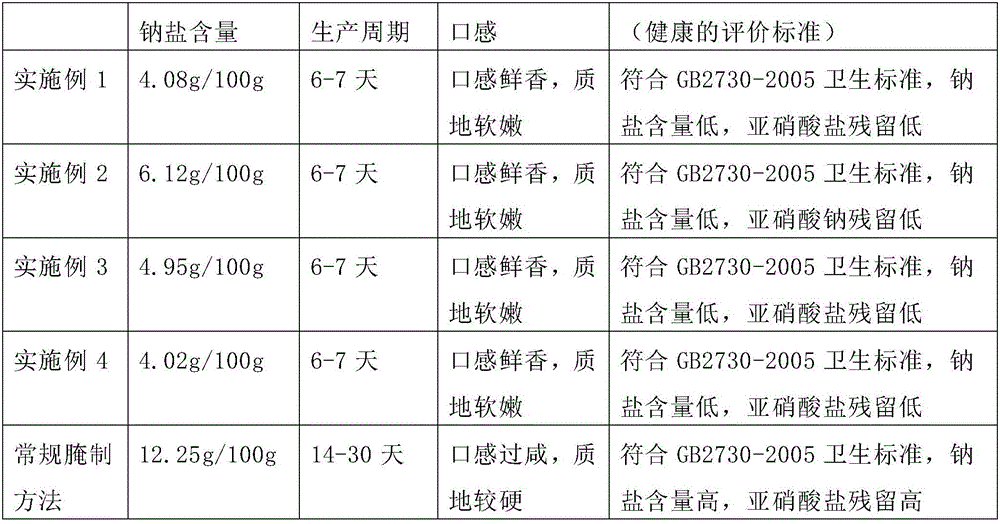

A processing method and low-sodium salt technology, which are applied in the directions of bacteria, alcohol-containing food ingredients, and inorganic compound-containing food ingredients used in food preparation, can solve the problems of long production cycle and high salt content, achieve outstanding sausage and reduce sodium Salt content, effect of speeding up curing and fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

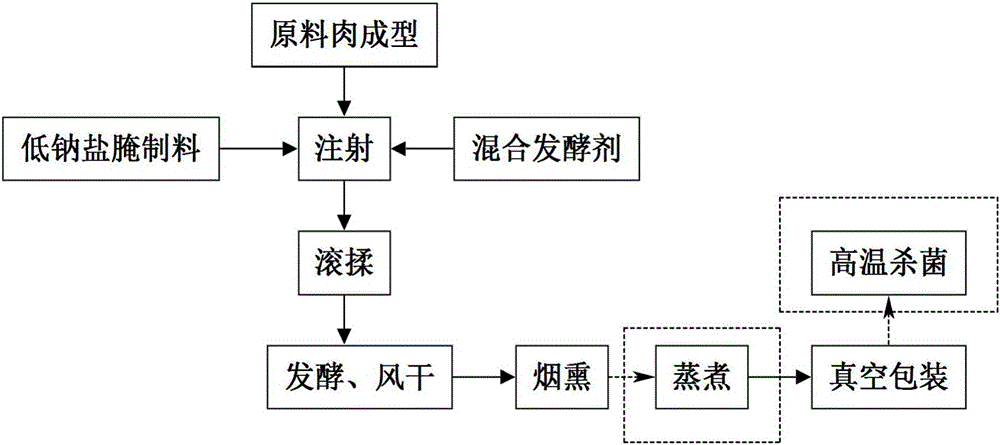

Method used

Image

Examples

Embodiment 1

[0029] A method for processing low-sodium salt quick-fermented cured bacon, comprising the following steps:

[0030] (1) Forming: Cut the beef into strips with a length of 18-25 cm, a width of 6-8 cm, and a thickness of 3-5 cm; or form or cut the whole poultry carcass into required shapes.

[0031] (2) Injection: the mixed starter (Lactobacillus casei: Lactobacillus rice wine colony number concentration ratio is 1:1) according to 1 × 10 6 The cfu / g inoculum amount and the low-sodium-salt mixed marinade are dissolved with an appropriate amount of water, and evenly injected into the pork with a salt water injection machine.

[0032] (3) Tumbling: Put the injected meat together with the outflowing injection into a tumbler with a vacuum of 0.08Mpa, a rotational speed of 15r / min, and a temperature of 12°C, using intermittent tumbling for 3 hours.

[0033] (4) Fermentation and air-drying: After tumbling, hang the meat in the fermentation room, the humidity is 65%, the wind speed is...

Embodiment 2

[0037] A method for processing low-sodium salt quick-fermented cured bacon, comprising the following steps:

[0038] (1) Forming: Cut the yak meat into strips with a length of 18-25 cm, a width of 6-8 cm, and a thickness of 3-5 cm; or form or cut the whole poultry carcass into required shapes.

[0039] (2) Injection: the mixed starter (Lactobacillus casei: Lactobacillus rice wine colony number concentration ratio is 1:1) according to 1 × 10 6 The cfu / g inoculum amount and the low-sodium-salt mixed marinade are dissolved with an appropriate amount of water, and evenly injected into the pork with a salt water injection machine.

[0040] (3) Tumbling: put the injected meat together with the outflowing injection into a tumbler with a vacuum of 0.08Mpa, a rotational speed of 15r / min, and a temperature of 16°C, using intermittent tumbling for 3 hours.

[0041] (4) Fermentation: After tumbling, hang the meat in the fermentation room, the humidity is 68%, the wind speed is 3.5m / s, th...

Embodiment 3

[0045] A method for processing low-sodium salt quick-fermented cured bacon, comprising the following steps:

[0046] (1) Forming: Cut the streaky pork with skin into 18-25cm long, 6-8cm wide, and 3-5cm thick strips; or form or cut the whole poultry carcass into required shapes.

[0047] (2) Injection: the mixed starter (Lactobacillus casei: Lactobacillus rice wine colony number concentration ratio is 1:1) according to 1 × 106 The cfu / g inoculum amount and the low-sodium-salt mixed marinade are dissolved with an appropriate amount of water, and evenly injected into the pork with a salt water injection machine.

[0048] (3) Tumbling: Put the injected meat together with the outflowing injection into a tumbler with a vacuum of 0.08Mpa, a rotational speed of 15r / min, and a temperature of 14°C, using intermittent tumbling for 3 hours.

[0049] (4) Fermentation: After tumbling, hang the meat in the fermentation room, humidity 70%, wind speed 3m / s, temperature 28-30°C, let stand for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com