Preparation method of zinc oxide-bismuth oxide thin film varistor

A zinc oxide film, varistor technology, applied in varistor cores, varistors, coating resistance materials, etc., can solve the complex process, low nonlinear coefficient of thin film varistor, difficult to construct problems, to achieve the effect of controllable composition, strictly controllable film deposition and hot dipping conditions, uniform structure and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

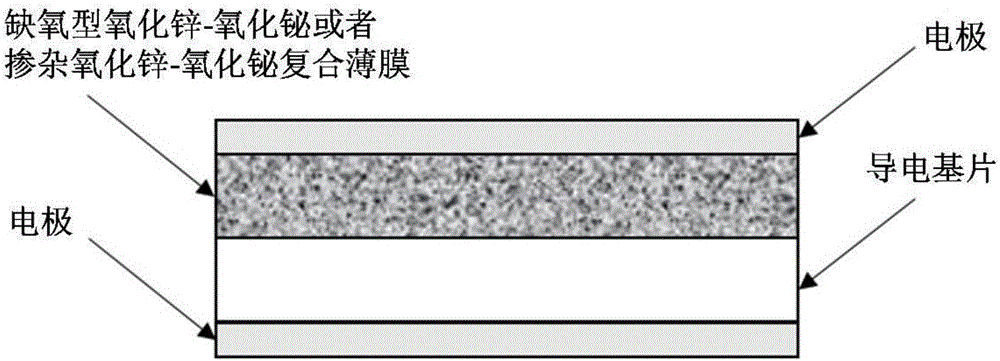

[0035] The preparation method of the zinc oxide-bismuth oxide film varistor proposed by the present invention comprises the following steps and contents:

[0036] (1) In radio frequency magnetron sputtering equipment, sintered ZnO with non-stoichiometric ratio n (n=0.6-0.99) is the matrix target, one or more of metal Fe, Co, Ni, Mn and their oxides is the doping target, and the target is fixed on the target position; the clean substrate Fix it on the sample stage; turn on the mechanical pump to low vacuum, turn on the molecular pump when the vacuum degree of the system reaches 0.1Pa, until the vacuum degree of the system reaches 2×10 -4 Above Pa.

[0037] (2) Pass in the working gas argon with a purity of more than 99.99vol.%, and first perform pre-sputtering for 2-10 minutes to remove the pollutants on the target surface; when the glow stabilizes, start the sputtering of the zinc oxide film shot deposition.

[0038] (3) Take out the prepared thin film sample from the magne...

Embodiment 1

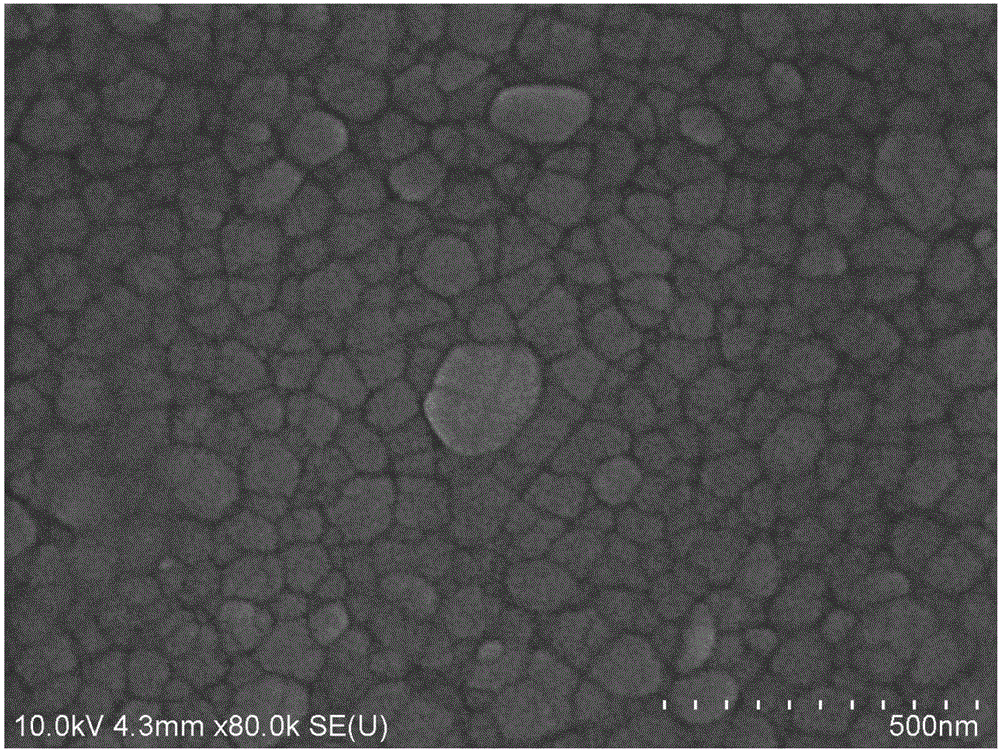

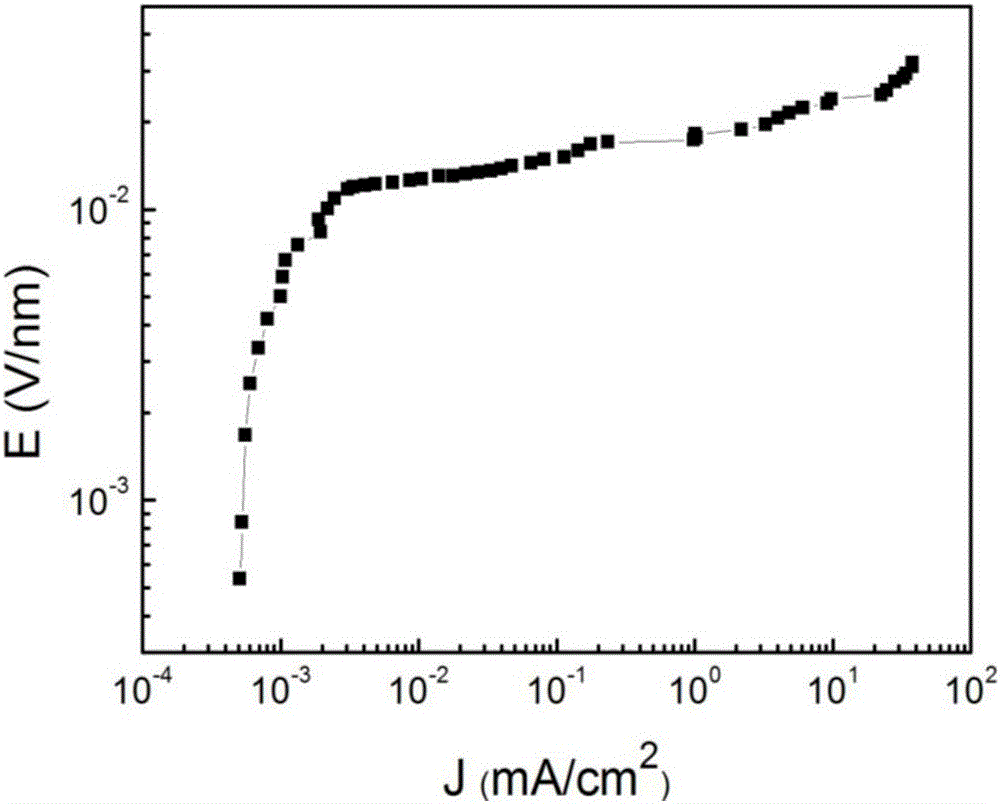

[0046] Embodiment 1: ZnO 0.78 The target and the clean highly doped conductive silicon substrate are fixed on the corresponding positions of the radio frequency magnetron sputtering equipment, the chamber is closed, the mechanical pump is first turned on to a low vacuum of 0.1Pa, and then the molecular pump is turned on to a high vacuum of 2×10 -4 Pa. Introduce high-purity argon gas, and pre-sputter for 10 minutes. Deposited at ambient temperature followed by Ar / O 2 The mixed gas ratio is 1:1, the sputtering power is 220W, the sputtering pressure is 1.0Pa, and the deposition time is 20min. An oxygen-deficient zinc oxide film was obtained. Then, the prepared ZnO film was embedded in analytically pure Bi 2 o 3 Soak in powder at 400°C for 40 minutes, and then cool the sample to room temperature with the furnace. Coat the upper and lower surfaces of the sample with silver paste as electrodes, and solder the leads to obtain a varistor, and test its pressure-sensitive performa...

Embodiment 2

[0048] Embodiment 2: the ZnO 0.99 The target, pure Fe target and clean highly doped conductive silicon substrate are fixed on the corresponding positions of the magnetron sputtering equipment, the chamber is closed, the mechanical pump is first turned on to a low vacuum of 0.1Pa, and then the molecular pump is turned on to a high vacuum of 2 ×10 -4 Pa. Introduce high-purity argon gas, and pre-sputter for 2 minutes. Deposition at ambient temperature, only argon, and ZnO at the same time 0.99 Target material and pure Fe target, the sputtering power is 60W, the sputtering pressure is 2.0Pa, and the deposition time is 60min. An iron-doped zinc oxide film was obtained. Then, the prepared ZnO film was embedded in analytically pure Bi 2 o 3 Hot soak in the powder at a temperature of 500°C for 60 minutes, and then cool the sample to room temperature with the furnace. Coat the upper and lower surfaces of the sample with silver paste as electrodes, and weld the leads to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current | aaaaa | aaaaa |

| Varistor voltage | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com