Manganese ore phase analyzing method

A technology of phase analysis and manganese ore, which is applied in the preparation of test samples, soil material testing, color/spectral characteristic measurement, etc., can solve the problems of serious cross-phase, low efficiency, large error, etc., and achieve large error , Improve accuracy and reduce the effect of series phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

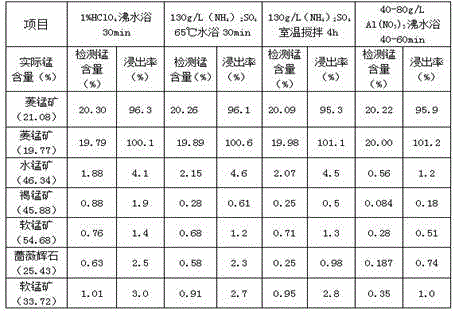

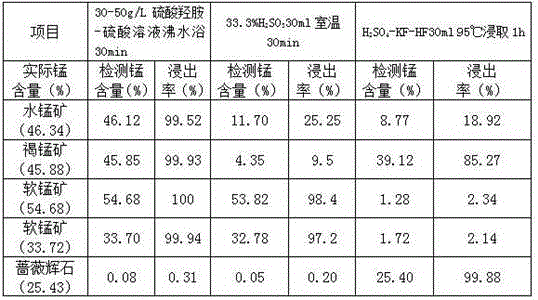

Examples

Embodiment 1

[0030] (1) Weigh 0.1g of 160 mesh rhodochrosite and place it in a 100mL beaker, in which the manganese content is 21.08%, add 50mL of aluminum nitrate solution with a concentration of 40g / L, cover with a watch glass, put it into a boiling water bath, After the water boils again, start timing and stir once every 8 minutes (note that after the water in the water bath is reduced, additional boiling water should be added), bathe in water for 40 minutes, and filter with slow quantitative filter paper (in order to prevent diafiltration, add water to the filter paper). filter pulp), collect the filter residue, and determine the manganese carbonate phase in the filtrate;

[0031] (2) Put the filter residue described in step (1) together with the filter paper into the original beaker, add 50mL 30g / L hydroxylamine sulfate-1% sulfuric acid solution, put it into the boiling water bath, wait for the water to boil again, start timing, Stir once every 10 minutes, take a water bath for 20 min...

Embodiment 2

[0034] (1) Weigh 0.2g of 200 mesh rhodochrosite and place it in a 100mL beaker, in which the manganese content is 19.77%, add 50mL of aluminum nitrate solution with a concentration of 50g / L, cover with a watch glass, put it in a 95°C water bath, etc. After the water temperature reaches 95°C again, start timing and stir once every 10 minutes (note that after the water in the water bath is reduced, add hot water at 95°C), bathe in water for 60 minutes, and filter with slow quantitative filter paper (in order to prevent diafiltration, Add filter pulp to the filter paper), collect the filter residue, and measure the manganese carbonate phase in the filtrate;

[0035] (2) Put the filter residue described in step (1) together with the filter paper into the original beaker, add 50mL 30g / L hydroxylamine sulfate-3% sulfuric acid solution, put it in a 95°C water bath, wait until the water temperature reaches 95°C again, start timing , stirring once every 10 minutes, water bath for 30 mi...

Embodiment 3

[0038] (1) Weigh 0.1g of 150-mesh manganese ore and place it in a 100mL beaker, in which the manganese content is 46.34%, add 50mL of aluminum nitrate solution with a concentration of 30g / L, cover with a watch glass, and put it into a boiling water bath. After the water boils again, start timing, and stir once every 10 minutes (note that after the water in the water bath is reduced, additional boiling water should be added), bathe in water for 70 minutes, and filter with slow quantitative filter paper (in order to prevent diafiltration, add water to the filter paper). filter pulp), collect the filter residue, and determine the manganese carbonate phase in the filtrate;

[0039] (2) Put the filter residue described in step (1) together with the filter paper into the original beaker, add 50mL 50g / L hydroxylamine sulfate-3% sulfuric acid solution, put it into the boiling water bath, wait for the water to boil again, start timing, Stir once every 10 minutes, take a water bath for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com