Total heat exchange heat recovery film and its manufacturing process and equipment

A technology of total heat exchange and heat recovery, applied in heat recovery systems, lighting and heating equipment, energy recovery systems for ventilation and heating, etc., can solve problems such as poor strength, low heat exchange rate, and high cost of heat recovery membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0104] Raw materials and the mass ratio of each substance are shown in the table below:

[0105]

[0106]

[0107] The preparation process is as follows:

[0108] 2. The manufacturing process of the total heat exchange heat recovery membrane (number 0# in this embodiment) of this embodiment:

[0109] (1.1) Grinding of seed crystal materials: SiO2 / Al2O3 / Na2O / CDA materials are mixed according to the ratio described in Example 1 and ground into fine powder on a grinder, and particles with a particle diameter of ≤7 μm are screened out with a dust sieve.

[0110] (1.2) Dilute spray paint: dilute and mix tetrahydrofuran solvent and SiO2 / Al2O3 / Na2O / CDA mixed powder in a ratio of 50:1, and stir evenly.

[0111] (1.3) Spraying seed crystals: Install natural cellulose film (original pulp paper film) on the spraying line of the special pervaporation production line, spray zeolite powder and tetrahydrofuran dry solvent on both sides of the natural cellulose film, and the coating th...

Embodiment 9

[0117] see Figure 8 , this embodiment is called 32# film in the design process,

[0118] (1) 32# membrane solution ingredients: C2H6O / CH4O / LiCl / H2O / SiO2 ratio is 7 / 9 / 98 / 3 / 888. Pay attention to the 32# membrane solution ingredients and mixing, methanol and ethanol have alcohol smell, And it is flammable, pay attention to the protection of fire prevention and alcohol poisoning.

[0119] (2) Immersion: in the immersion section of the 32# membrane production line. Install the cellulose substrate on the roll paper stand, and pass it through the guide rollers and the solution tank, and roll the other end of the original pulp paper on the roll machine; install the prepared 32# membrane solution in the solution tank. Start the motor of the winder. Pay attention to adjust the immersion time within 5-20 minutes according to the ambient temperature, so as to ensure that the original pulp paper is soaked. Note: The operator should not spend more than 60 minutes between processing in ...

Embodiment 10

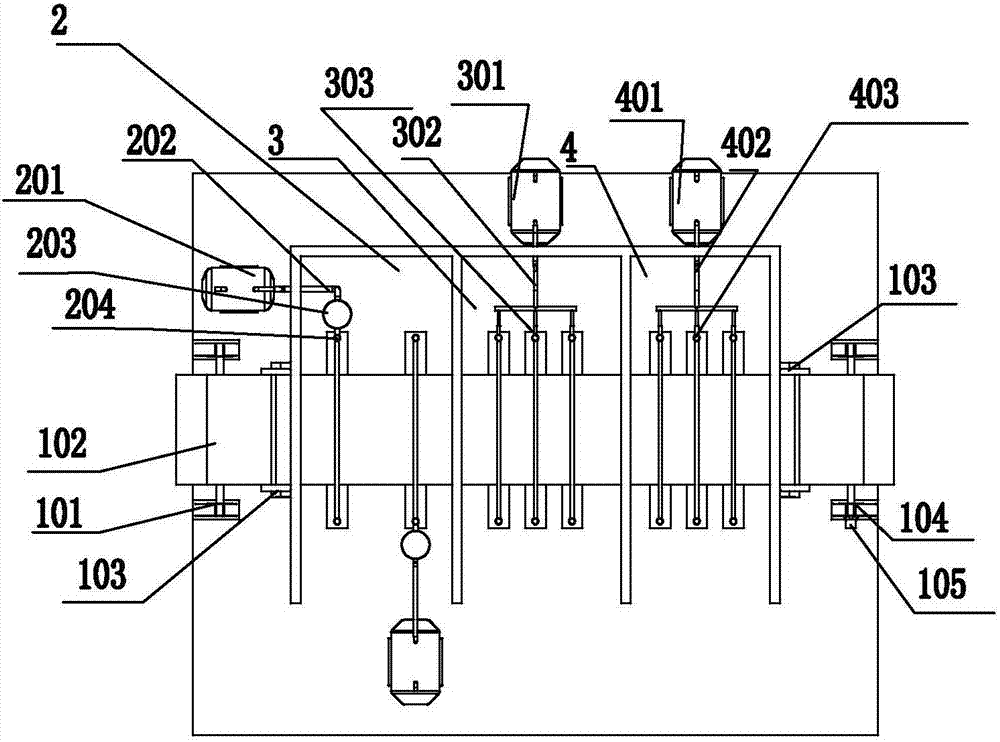

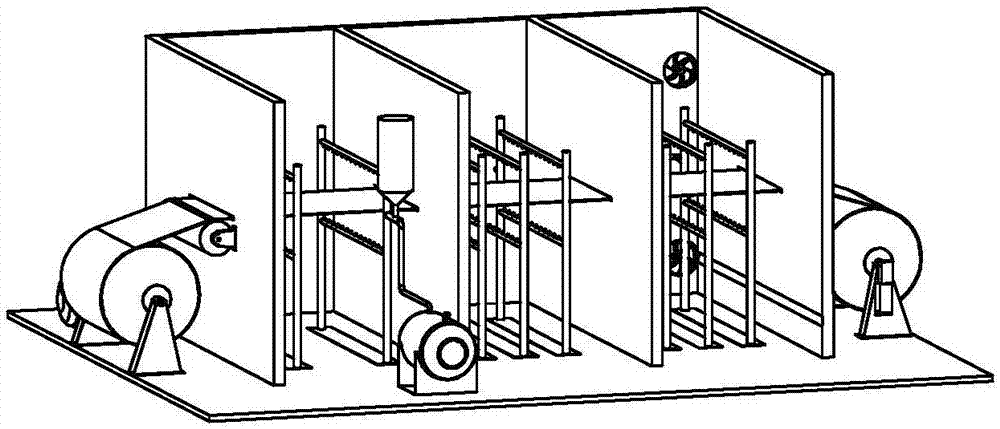

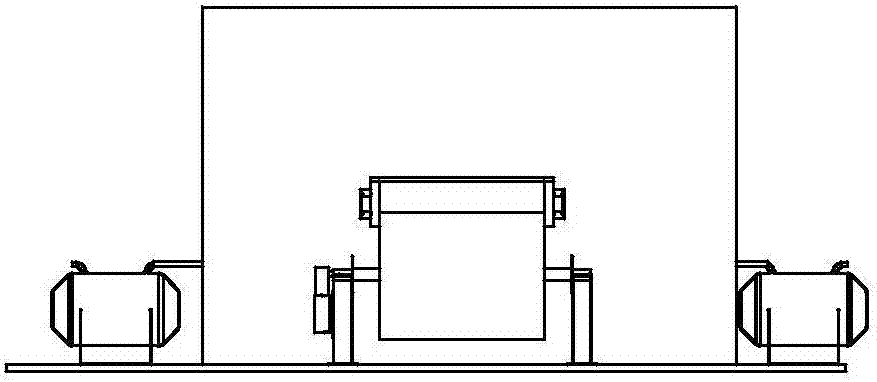

[0124] see Figure 1-3 Schematic diagram of the structure of the heat recovery membrane pervaporation production system in this example:

[0125]1 roll paper system, 101 roll paper stand, 102 raw pulp paper roll, 103 drum, 104 roll machine, 105 motor and speed control box;

[0126] 2 Spray section of permeation line, 201 drying air compressor, 202 pipeline, 203 mixed solvent cylinder, 204 spray rack;

[0127] 3 pervaporation and crystallization treatment section, 301 steam generator, 302 steam pipeline, 303 steam injection rack;

[0128] 4 Permeation gasification drying section, 401 drying air compressor, 402 pipeline, 403 blowing frame, 404 ventilation fan.

[0129] In this embodiment, the heat recovery membrane pervaporation production line is closed production, and the power equipment is installed outside the production line. The production line is divided into three sections. Three sections and four infiltration gasification and drying sections. In addition to the power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com