Method for preparing high-temperature-resistant oxidation coating on surface of carbon/carbon composite material

A carbon composite material, high-temperature oxidation-resistant technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of reduced oxidation resistance and low bonding strength, so as to improve bonding strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of high temperature oxidation resistant coating of carbon / carbon composite material

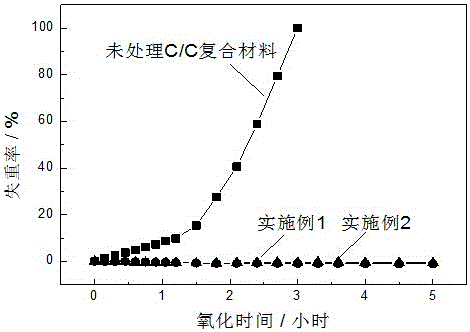

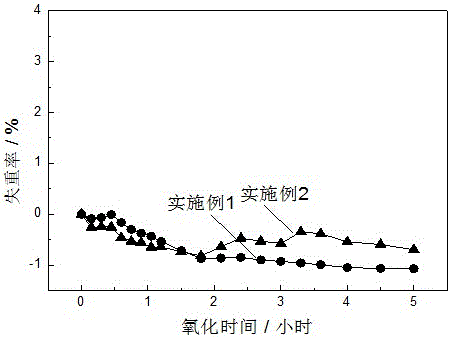

[0026] In this embodiment, plasma surface activation technology and double-glow plasma surface metallurgy technology are used to etch the surface of carbon / carbon composite workpiece with hydrogen plasma; Chromium is infiltrated into the surface of the infiltrated layer to form a nickel-chromium alloy coating on the surface of the workpiece. Finally, hydrogen gas is introduced to carry decamethylcyclopentasiloxane and oxygen as reaction gases to prepare a composite coating of chromium oxide and silicon oxide on the surface of the workpiece. . The schematic diagram of the prepared high-temperature oxidation-resistant coating is attached figure 1 shown. Specifically include the following steps:

[0027](1) The surface activation treatment process of the workpiece is as follows: put the carbon / carbon composite material workpiece into the microwave plasma e...

Embodiment 2

[0033] A kind of preparation method of high temperature oxidation resistant coating of carbon / carbon composite material

[0034] The coating preparation method for improving the high-temperature oxidation resistance of carbon / carbon composite materials provided in this embodiment specifically includes the following steps:

[0035] (1) The surface activation treatment process of the workpiece is as follows: put the carbon / carbon composite material workpiece into the microwave plasma enhanced experimental device, evacuate the vacuum to below 1Pa, inject hydrogen with a flow rate of 200sccm, working pressure of 6.2kPa, microwave power of 2kW, The etching time is 60min, and the surface activation treatment is carried out;

[0036] (2) The preparation process of the nickel infiltrated layer is as follows: put the etched carbon / carbon composite material workpiece into the double-glow plasma surface metallurgy device, use the nickel metal target with a thickness of 5mm and a purity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com