Ultralow-temperature-resistant high-strength rubber asphalt waterproof material, and preparation and construction methods thereof

A technology of rubber asphalt and waterproof materials, applied in the field of materials, can solve the problems of poor low temperature resistance, failure to reach, and low tensile strength of waterproof coatings, and achieve the effect of small construction environment requirements and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

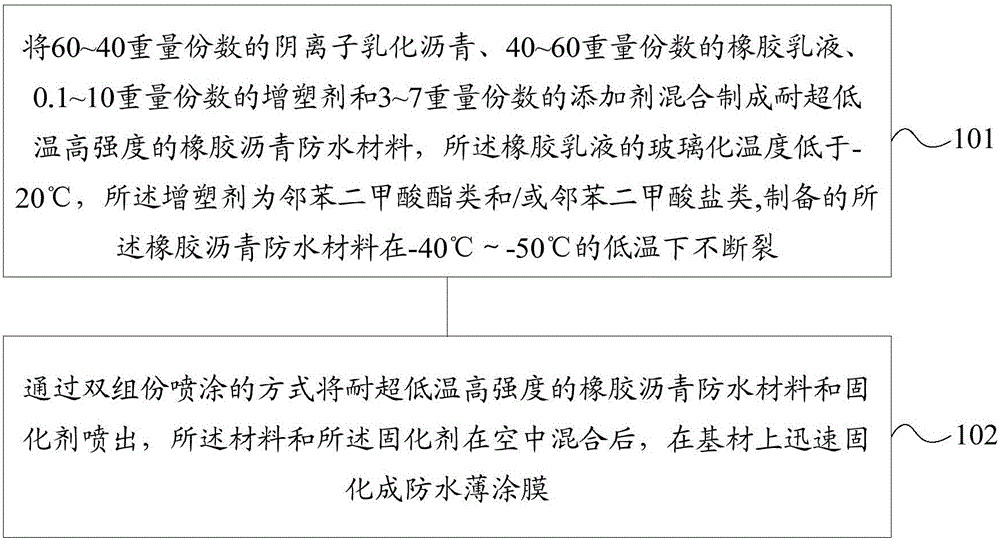

[0058] Mix 60 parts of anionic emulsified asphalt, 40 parts of rubber emulsion, 0.1 part of plasticizer and 3 parts of additives to make ultra-low temperature resistant and high-strength rubber asphalt waterproof material. It will not break at a low temperature of 40°C to -50°C.

[0059] Wherein, the anion-emulsified asphalt includes anion-emulsified asphalt modified by rubber emulsion.

[0060] The rubber latex is made by mixing synthetic rubber and natural rubber latex. The synthetic rubber includes chloroprene rubber. The glass transition temperature of the rubber latex is lower than -20°C.

[0061] Plasticizers include dibutyl phthalate.

[0062] Among the additives, the surfactant includes rosin soap and fatty acid soap; the dispersant includes sodium polynaphthalene sulfonate; the stabilizer includes sodium alkyl sulfate; and the sunscreen includes hindered amine light stabilizer.

[0063] After that, the ultra-low temperature-resistant and high-strength rubber asphalt...

Embodiment 2

[0065] Mix 40 parts of anionic emulsified asphalt, 60 parts of rubber emulsion, 10 parts of plasticizer and 7 parts of additives to make ultra-low temperature resistant and high-strength rubber asphalt waterproof material. It will not break at a low temperature of 40°C to -50°C.

[0066] Among them, the anionic emulsified asphalt includes unmodified anionic emulsified asphalt.

[0067] Rubber latex is made by mixing synthetic rubber and natural rubber latex. Synthetic rubber includes chloroprene rubber, styrene-butadiene rubber, nitrile rubber and butadiene rubber. The glass transition temperature of rubber latex is lower than -20°C.

[0068] The plasticizer is dioctyl phthalate.

[0069] Among the additives, surfactants include alkyl diphenyl ether disulfonate and sodium methyl oleate sulfonate; dispersants include sodium polynaphthalene sulfonate; stabilizers include sodium alkyl sulfate; sunscreens include hydrophilic Aqueous liquid mixture of 2-(2-hydroxyphenyl)-benzotri...

Embodiment 3

[0072] Mix 50 parts of anionic emulsified asphalt, 50 parts of rubber emulsion, 5 parts of plasticizer and 5 parts of additives to make ultra-low temperature resistant and high-strength rubber asphalt waterproof material. It will not break at a low temperature of 40°C to -50°C.

[0073] Wherein, the anionic emulsified asphalt includes unmodified anionic emulsified asphalt and anionic emulsified asphalt modified by rubber emulsion.

[0074] Rubber emulsion is made by mixing synthetic rubber and natural rubber emulsion. Synthetic rubber includes chloroprene rubber, styrene-butadiene rubber, nitrile rubber, EPDM rubber, isoprene rubber and butadiene rubber. The glass transition temperature of rubber emulsion is low at -20°C.

[0075] The plasticizers are dibutyl phthalate and dioctyl phthalate.

[0076] Among the additives, the surfactant includes nonylphenol polyoxyethylene ether; the dispersant includes sodium polynaphthalene sulfonate; the stabilizer includes sodium alkyl su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com