Wear-resistant resin spectacle lens and preparation technology thereof

A technology of resin spectacle lenses and wear-resistant resin, applied in the optical field, can solve the problems of poor surface wear resistance of composite spectacle lenses, reduced service life of spectacle lenses, heavy composite spectacle lenses, etc. Lightweight and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

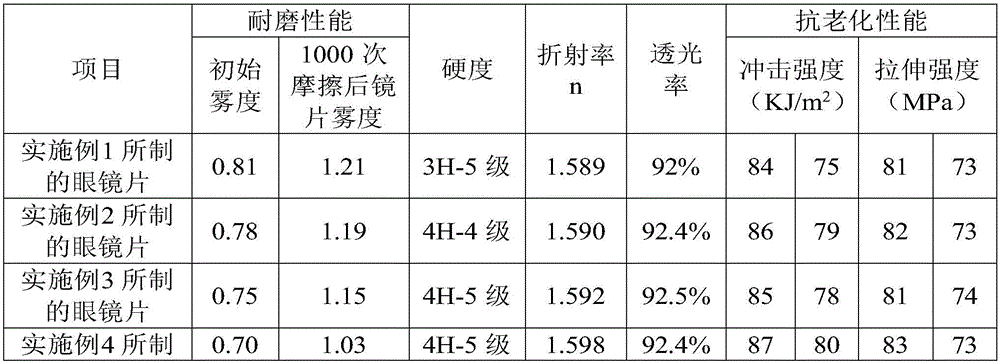

Examples

Embodiment 1

[0035] A wear-resistant resin spectacle lens, the raw materials and weight percentages for preparing the resin spectacle lens are: 50% polymethyl methacrylate, 15% bisphenol A polycarbonate, 10% silicone acrylic resin, tert-butyl polyacrylate 0.2%, linear low density polyethylene 0.05%, oxazoline 2%, catechol 1%, β-naphthylamine 0.1%, dodecyl dihydroxyethyl betaine 1%;

[0036] The molecular weight of polymethyl methacrylate is 30000, and the melt index measured at 190°C and 21.6Kg according to GB-T3682 is 130g / 10min;

[0037] Wherein the molecular weight of bisphenol A type polycarbonate is 15000, and molecular mass distribution is 2.0;

[0038] Among them, the viscosity of the silicone acrylic resin at 60°C is 25Pa·s;

[0039] The molecular weight of tert-butyl polyacrylate is 13000, and the melt index measured at 190°C and 21.6Kg according to GB-T3682 is 350g / 10min;

[0040] Among them, the molecular mass distribution of linear low density polyethylene is 1.8.

Embodiment 2

[0042] A wear-resistant resin spectacle lens, the raw materials and weight percentages of the resin spectacle lens are: 65% polymethyl methacrylate, 35% bisphenol A polycarbonate, 15% silicone acrylic resin, tert-butyl polyacrylate 0.5%, linear low density polyethylene 0.10%, oxazoline 6%, catechol 3%, β-naphthylamine 0.3%, dodecyl dihydroxyethyl betaine 5%;

[0043] The molecular weight of polymethyl methacrylate is 45000, and the melt index measured at 190°C and 21.6Kg according to GB-T3682 is 170g / 10min;

[0044] Wherein the molecular weight of bisphenol A type polycarbonate is 25000, and molecular mass distribution is 4.0;

[0045] Among them, the viscosity of silicone acrylic resin at 60°C is 50Pa·s;

[0046] The molecular weight of tert-butyl polyacrylate is 30,000, and the melt index measured at 190°C and 21.6Kg according to GB-T3682 is 500g / 10min;

[0047] Wherein the molecular mass distribution of linear low density polyethylene is 3.0.

Embodiment 3

[0049] A wear-resistant resin spectacle lens, the raw materials and weight percentages of the resin spectacle lens are: 55% polymethyl methacrylate, 20% bisphenol A polycarbonate, 12% silicone acrylic resin, tert-butyl polyacrylate 0.2%, linear low density polyethylene 0.06%, oxazoline 3%, catechol 1.5%, β-naphthylamine 0.15%, dodecyl dihydroxyethyl betaine 1.5%;

[0050] Among them, the molecular weight of polymethyl methacrylate is 32500, and the melt index measured according to GB-T3682 at 190°C and 21.6Kg is 140g / 10min;

[0051] Wherein the molecular weight of bisphenol A type polycarbonate is 17500, and molecular mass distribution is 2.5;

[0052] Among them, the viscosity of silicone acrylic resin at 60°C is 30Pa·s;

[0053] The molecular weight of tert-butyl polyacrylate is 18000, and the melt index measured at 190°C and 21.6Kg according to GB-T3682 is 380g / 10min;

[0054] The molecular mass distribution of linear low density polyethylene is 2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com