Preparation method for producing pig haemocyte active small peptide powder through one-step method

A technology of active small peptides and porcine blood cells, which is applied in the field of animal blood protein deep processing, can solve the problems of simplicity and operability, insufficient nutritional value and functionality of products, no report on active small molecular peptide content, and easy denaturation of hemoglobin. Achieve the effect of improving animal immunity and disease resistance, easy absorption and utilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

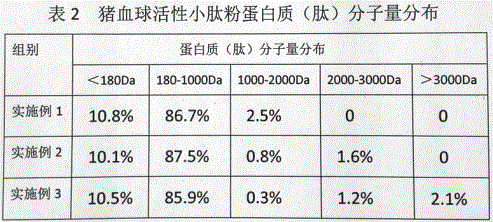

Examples

Embodiment 1

[0028] (1) Preparation of porcine blood cells: collect 1000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 440L of blood cells and 560L of plasma, collect the blood cells, and spray dry the plasma to make plasma protein powder Add food-grade sodium citrate during anticoagulant treatment, the addition amount is 0.4% of fresh pig blood weight, the sodium citrate that weighs is mixed with 10% sodium citrate solution first, then in the process of collecting fresh pig blood Slowly add the sodium citrate solution while stirring;

[0029] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 440L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 30r / min, and 880L of hemolysis is obtained;

[0030] (3) Enzymolysis: Heat the hemolysis to 50°C with continuous stirring, adjust the pH value to 8.5 with NaOH solution, then add 0.4% protease (enzyme act...

Embodiment 2

[0036] (1) Preparation of pig blood cells: collect 2000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 850L of blood cells and 1150L of plasma. Add food-grade sodium citrate during anticoagulant treatment, and the addition amount is 0.5% of fresh pig blood weight. Slowly add the sodium citrate solution while stirring;

[0037] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 850L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 50r / min to prepare 1700L of hemolysis;

[0038] (3) Enzymolysis: Heat the hemolysis to 55°C with continuous stirring, adjust its pH value to 8.5 with NaOH solution, then add 0.3% protease (enzyme activity 200,000U / ml) by weight of the blood cell solution, and keep stirring, every interval Check the pH value of the enzymolysis solution for one hour. When the pH value drops below 8.0, adjust the pH value of t...

Embodiment 3

[0044] (1) Preparation of porcine blood cells: collect 5000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 2160L of blood cells and 2840L of plasma, collect the blood cells, and spray dry the plasma to make plasma protein powder Add food-grade sodium citrate during anticoagulant treatment, and the addition amount is 0.5% of fresh pig blood weight. Slowly add the sodium citrate solution while stirring;

[0045] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 2200L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 50r / min to prepare 4360L of hemolysis;

[0046] (3) Enzymolysis: Heat the hemolysis to 55°C with continuous stirring, adjust the pH value to 8.5 with NaOH solution, then add 0.2% protease (enzyme activity 200,000U / ml) by weight of the blood cell solution, keep stirring, every interval Check the pH value of the enzymolysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com