Preparation technique of ethyl difluoroacetate

A technology of ethyl difluoroacetate and preparation process, applied in the chemical field, can solve the problems of large amount of three wastes, long process route, low total yield, etc., and achieve the effects of improving enterprise benefit, high product purity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

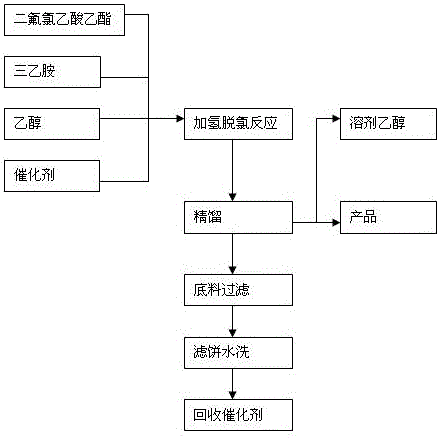

[0033] Such as figure 1 A kind of preparation technology of ethyl difluoroacetate shown is prepared from the raw materials of following mass parts:

[0034] 1 part ethyl difluorochloroacetate

[0035] 0.5 parts of triethylamine

[0036] 5 parts ethanol

[0037] Palladium carbon 0.002 part.

[0038] The preparation technology of above-mentioned a kind of ethyl difluoroacetate comprises the steps:

[0039] (1) Put 1 part of ethyl difluorochloroacetate, 0.5 parts of triethylamine, 5 parts of solvent ethanol and 0.002 parts of catalyst palladium carbon in the autoclave;

[0040] (2) Replace the air in the reactor with nitrogen for at least 3 times, then replace it with hydrogen for at least 3 times, and slowly raise the temperature to 30°C. At this time, the pressure of the reactor is about 0.1MPa;

[0041] (3) Then slowly feed hydrogen to the kettle pressure of 0.4MPa for hydrogenation reaction. When the pressure in the kettle drops to 0.1MPa, feed hydrogen again to the kett...

Embodiment 2

[0046] A preparation process of ethyl difluoroacetate, prepared from the following raw materials in parts by mass:

[0047] 2 parts ethyl difluorobromoacetate

[0048] 1.5 parts of triethylamine

[0049] Methanol 10 parts

[0050] Nickel 0.05 parts.

[0051] The preparation technology of above-mentioned a kind of ethyl difluoroacetate comprises the steps:

[0052] (1) Put 2 parts of ethyl difluorobromoacetate, 1.5 parts of triethylamine, 10 parts of solvent methanol and 0.05 parts of catalyst nickel in the autoclave;

[0053] (2) Replace the air in the reactor with nitrogen for at least 3 times, then replace it with hydrogen for at least 3 times, and slowly raise the temperature to 80°C. At this time, the pressure of the reactor is about 0.5MPa;

[0054] (3) Then slowly feed hydrogen to the kettle pressure of 1MPa for hydrogenation reaction. When the pressure in the kettle drops to 0.5MPa, feed hydrogen again to the kettle pressure of 1MPa;

[0055] (4) Repeat step (3) se...

Embodiment 3

[0059] A preparation process of ethyl difluoroacetate, prepared from the following raw materials in parts by mass:

[0060] 1.5 parts of ethyl difluoroiodoacetate

[0061] 1 part triethylamine

[0062] Tetrahydrofuran 7 parts

[0063] Palladium carbon 0.03 part.

[0064] The preparation technology of above-mentioned a kind of ethyl difluoroacetate comprises the steps:

[0065] (1) Put 1.5 parts of ethyl difluoroiodoacetate, 1 part of triethylamine, 7 parts of solvent tetrahydrofuran and 0.03 parts of catalyst palladium carbon into the autoclave;

[0066] (2) Replace the air in the reactor with nitrogen for at least 3 times, then replace it with hydrogen for at least 3 times, and slowly raise the temperature to 100°C, and the pressure of the reactor is about 0.1MPa;

[0067] (3) Then slowly inject hydrogen to the pressure of 2MPa to carry out the hydrogenation reaction. When the pressure in the kettle drops to 1MPa, inject hydrogen again to the pressure of 2MPa;

[0068] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com