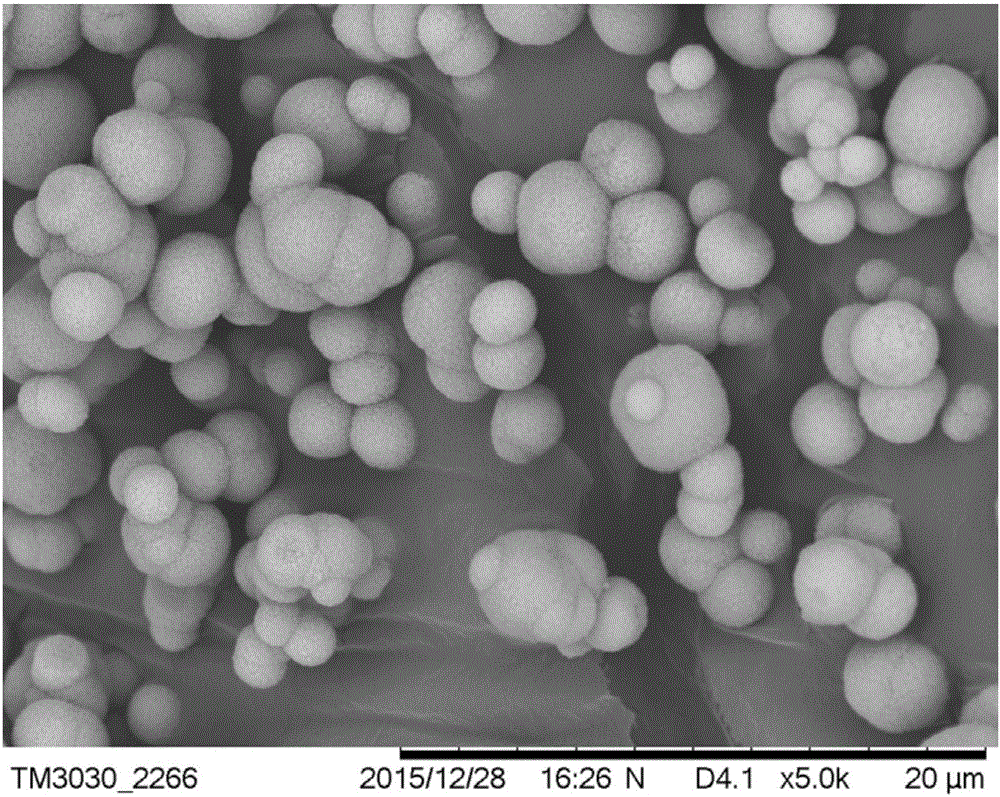

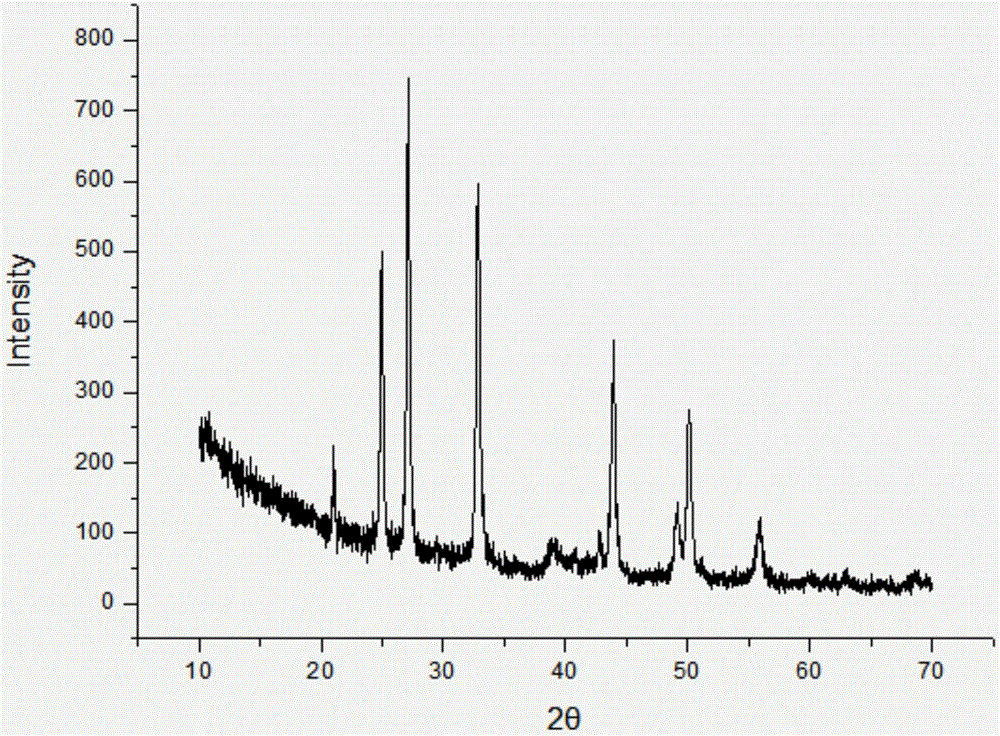

Preparation method and application for micron vaterite type food-grade calcium carbonate

A technology of calcium carbonate and vaterite, applied in the direction of calcium carbonate/strontium/barium, applications, food ingredients, etc., can solve problems such as unevenness, increase costs, increase processing procedures, etc., achieve uniform dispersion, reduce requirements, and improve carbonization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

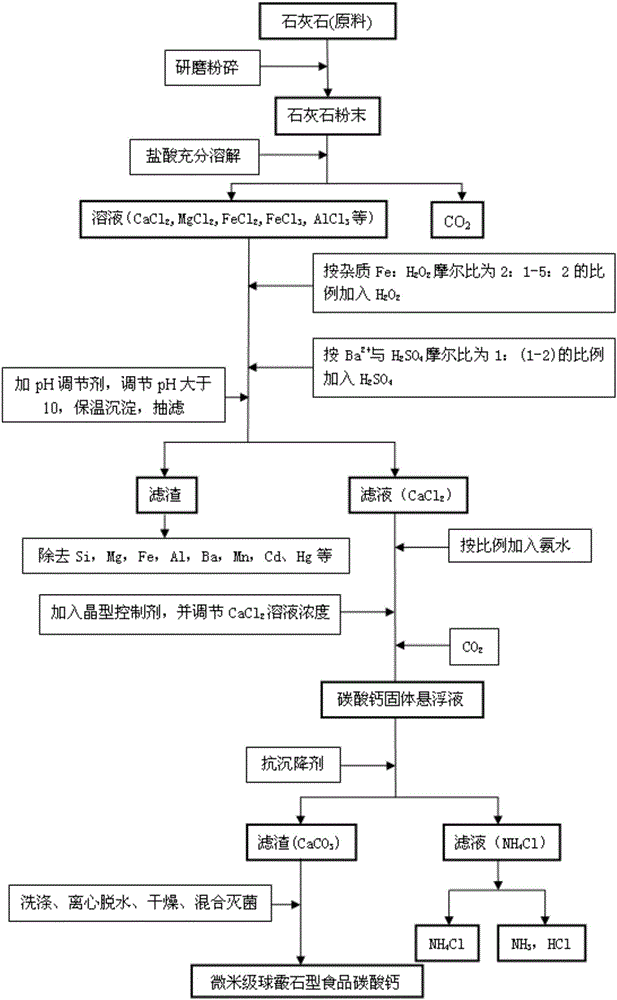

[0029] Step 1): Grinding and pulverizing the limestone into limestone powder with a fineness of 150 mesh.

[0030] Step 2): Add 5 mol / L hydrochloric acid solution to the limestone powder in step 1 at a molar ratio of hydrochloric acid:limestone of 1:1, and stir for 60 minutes at room temperature. CO collected from the reaction 2 gas.

[0031] Step 3): In the solution that step 2 obtains, add according to impurity Fe:H 2 o 2 Add H at a molar ratio of 2:1 2 o 2 , after the reaction is complete, press Ba 2+ with H 2 SO 4 Add H at a molar ratio of 1:1 2 SO 4 , heated to 80°C, and kept at a constant temperature for 20 minutes to precipitate barium ions. Then add Ca(OH) 2 , adjust the pH value to 11.5, remove Si, Fe, Mg, Al, Cd, Hg, Mn and other ions, and obtain CaCl by suction filtration 2 Clear solution.

[0032] Step 4): Press Ca to Step 3 2+ : The molar ratio of ammonia water is 1:2, adding 10mol / L ammonia water, and adding phosphoric acid with a volume percentage ...

Embodiment 2

[0039] Step 1): Grinding and pulverizing the limestone into limestone powder with a fineness of 100 mesh.

[0040] Step 2): Add 5 mol / L hydrochloric acid solution to the limestone powder in step 1 at a molar ratio of hydrochloric acid:limestone of 1.5:1, and stir for 60 minutes at room temperature. CO collected from the reaction 2 gas.

[0041] Step 3): In the solution that step 2 obtains, add according to impurity Fe:H 2 o 2 Add H at a molar ratio of 2:1 2 o 2 , after the reaction is complete, press Ba 2+ with H 2 SO 4 Add H at a molar ratio of 1:1 2 SO 4 , heated to 80°C, and kept at a constant temperature for 20 minutes to precipitate barium ions. Then add CaO, adjust the pH value to 11.5, remove Si, Fe, Mg, Al, Cd, Hg, Mn ions, and obtain CaCl by suction filtration 2 Clear solution.

[0042] Step 4): Press Ca to step 3 2+ : The molar ratio of ammonia water is 1:2, adding 10mol / L ammonia water, and adding sodium pyrophosphate with a volume percentage of 0.05%, ...

Embodiment 3

[0046] Step 1): Grinding and pulverizing the limestone into limestone powder with a fineness of 100 mesh.

[0047] Step 2): Add 5 mol / L hydrochloric acid solution to the limestone powder in step 1 at a molar ratio of hydrochloric acid:limestone of 2:1, and stir for 60 minutes at room temperature. CO collected from the reaction 2 gas.

[0048] Step 3): In the solution that step 2 obtains, add according to impurity Fe:H 2 o 2 Add H at a molar ratio of 2:1 2 o 2 , after the reaction is complete, press Ba 2+ with H 2 SO 4 Add H at a molar ratio of 1:1 2 SO 4 , heated to 80°C, and kept at a constant temperature for 20 minutes to precipitate barium ions. Then add ammonia water, adjust the pH value to 12, remove Si, Fe, Mg, Al, Cd, Hg, Mn ions, and obtain CaCl by suction filtration 2 Clear solution.

[0049] Step 4): Press Ca to Step 3 2+ : The molar ratio of ammonia water is 1:1, adding 10mol / L ammonia water, and adding sodium tripolyphosphate with a volume percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com