A Fluid Management System for Space Fuel Tank Based on Electric Field Effect

A technology of electric field effect and fluid management, which is applied in the field of fuel storage tank fluid management system, can solve problems such as the inability to predict the specific distribution, and achieve the effect of improving the management level of on-orbit service fluid, preventing spacecraft instability, and improving active control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

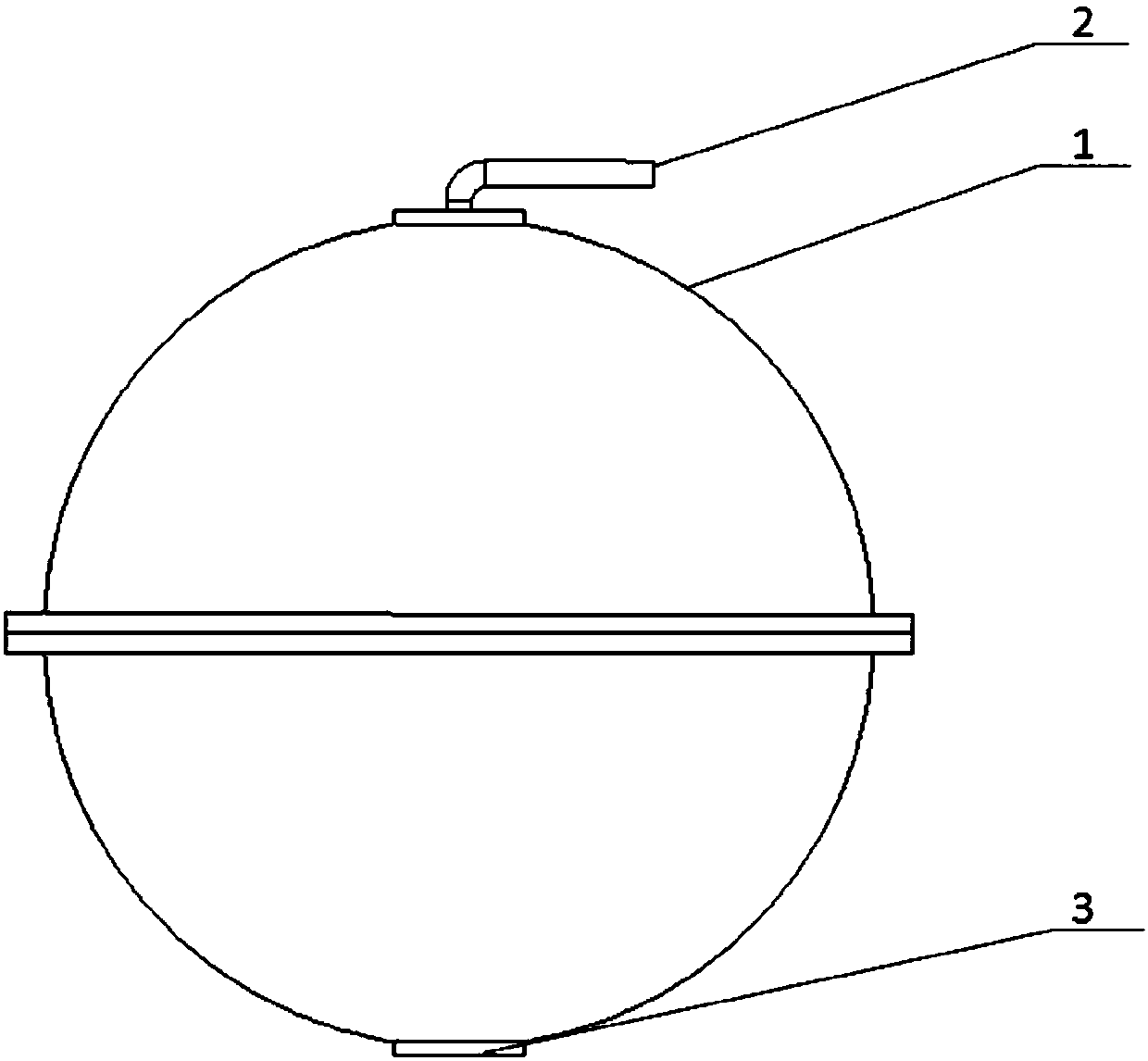

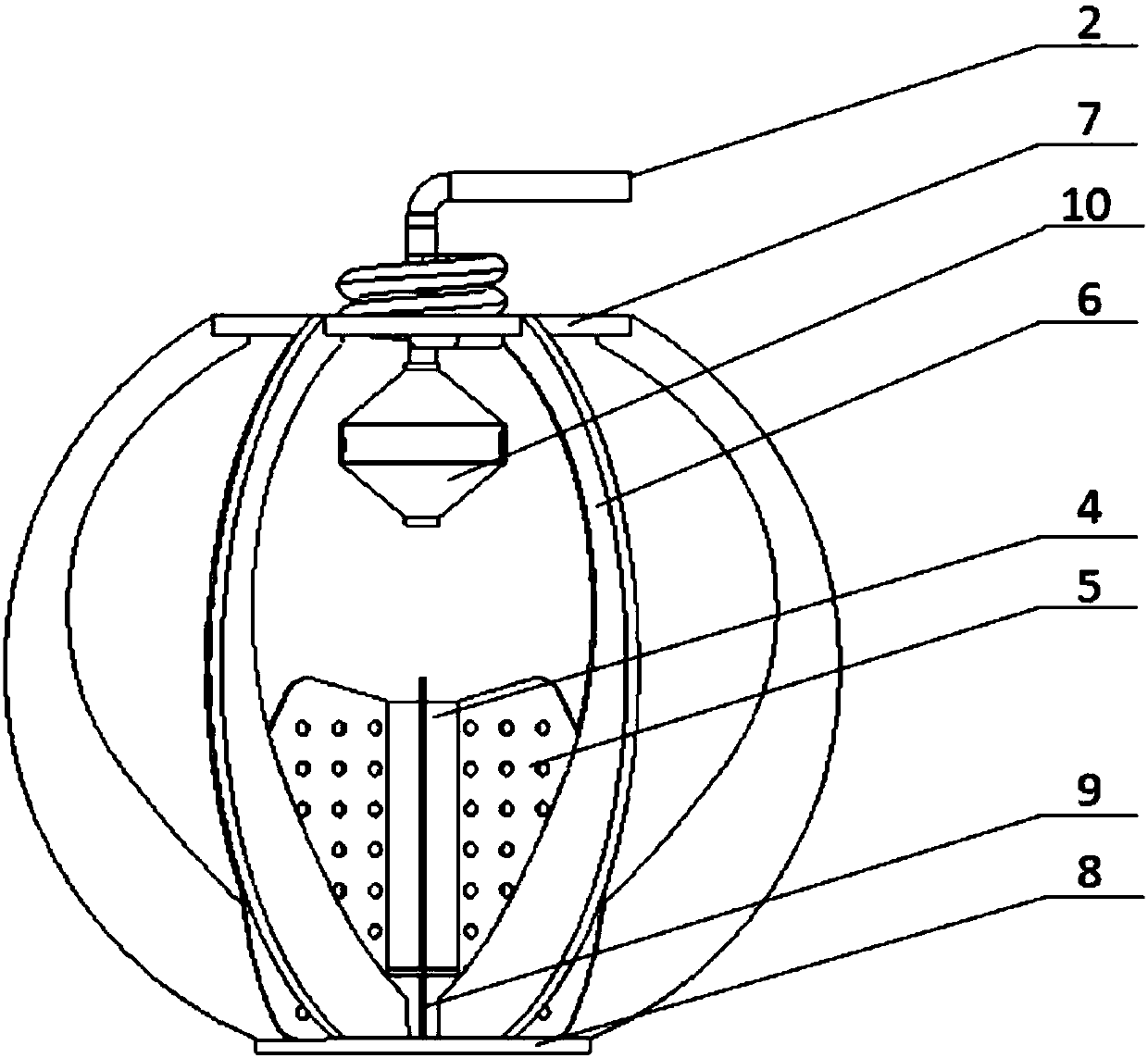

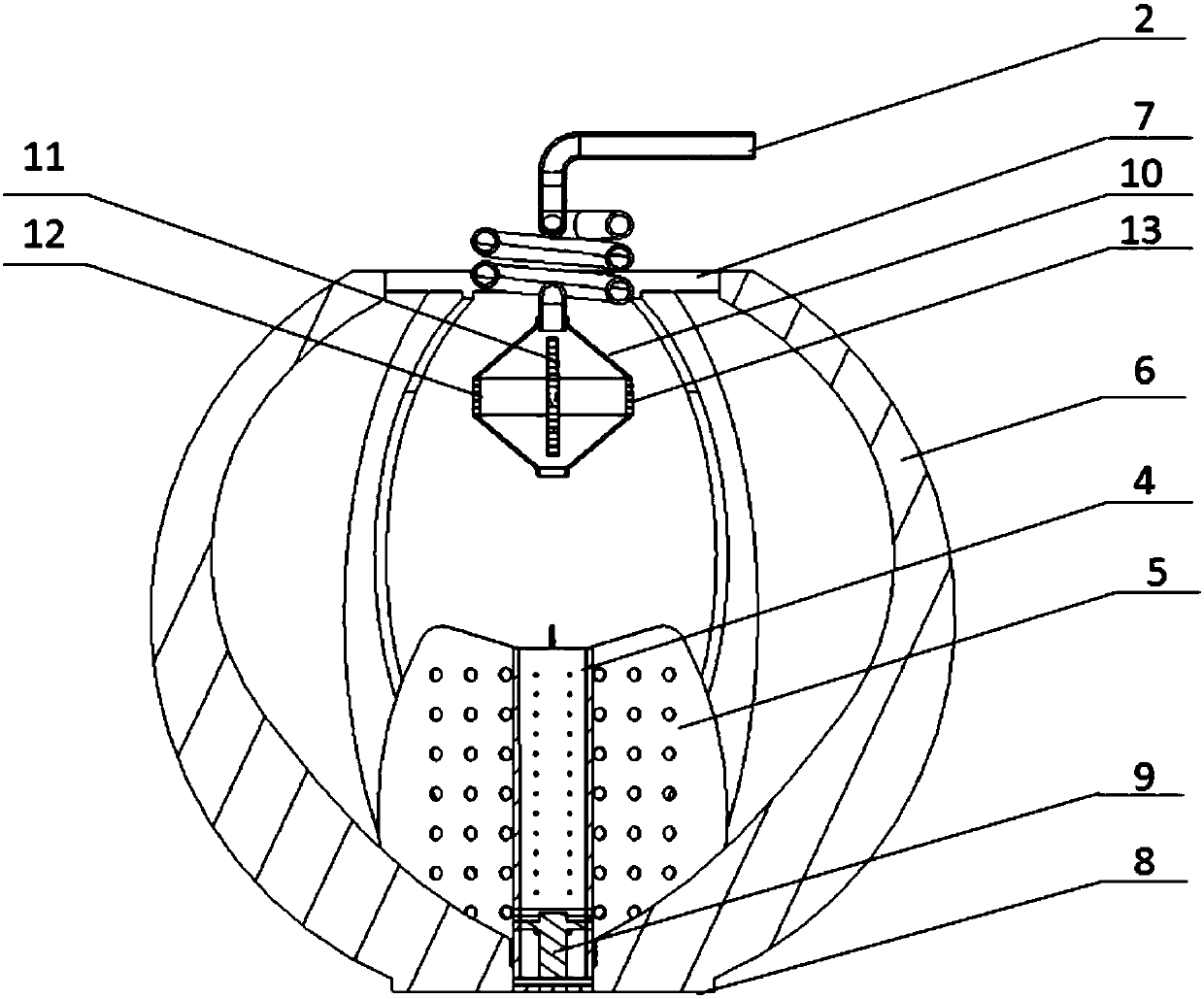

[0033] Such as Figure 1-5 Shown is a schematic diagram of a space fuel storage tank fluid management system based on electric field effects. The system includes: storage tank wall 1, exhaust pipe 2, drain / fill port 3, central cylinder 4 (upper cylinder 401, lower cylinder 402), Inner deflector 5, outer deflector 6, upper tray ring 7, lower tray 8, positive electrode rod 9, spindle-shaped container 10, positive electrode large disc 11, negative electrode small discs 12 and 13.

[0034] The center tube 4 of the space plate type surface tension fuel storage tank is composed of an upper tube 401 and a lower tube 402. There are a plurality of mm-scale small holes on the circumferential walls of the upper tube 401 and the lower tube 402. The upper tube 401 and the lower tube 402 are plugged together. Or the welded inner deflector 5 realizes upper and lower fixed connections. The interface between the upper cylinder 401 and the lower cylinder 402 and the outer peripheral surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com