Novel EHD spatial fuel storage tank gas-liquid phase separation management system

A management system, gas-liquid phase technology, applied in the field of new EHD space fuel tank gas-liquid phase separation management system, fuel tank fluid management system, can solve the problem that the specific distribution cannot be predicted, to improve the active control ability and in the The effect of improving the management level of orbital service fluid, improving mobility and reliability, and saving launch costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

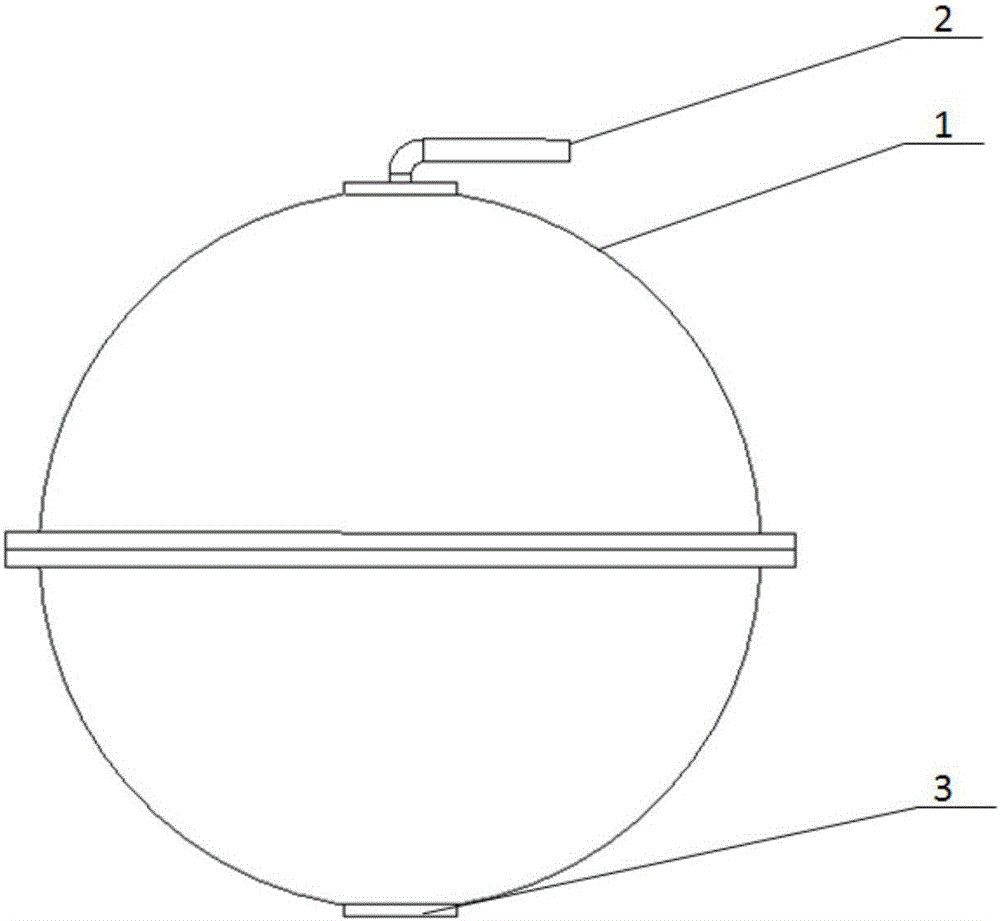

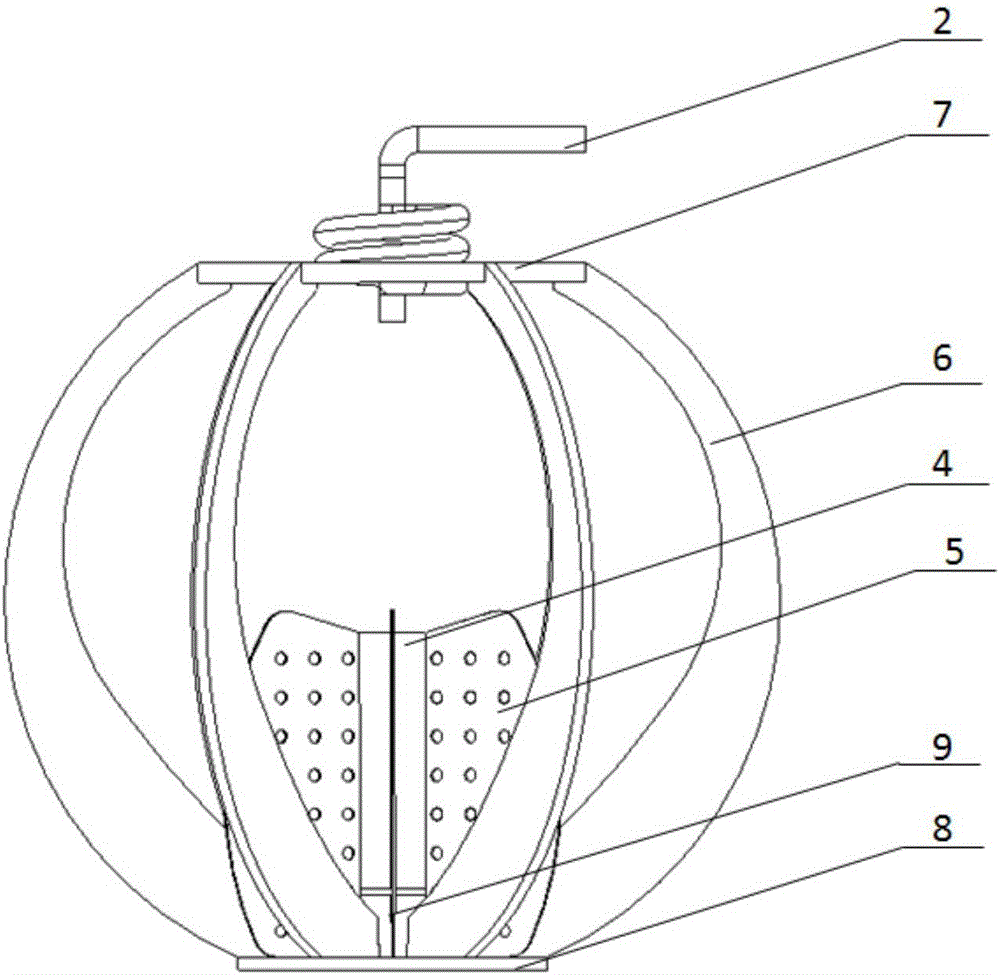

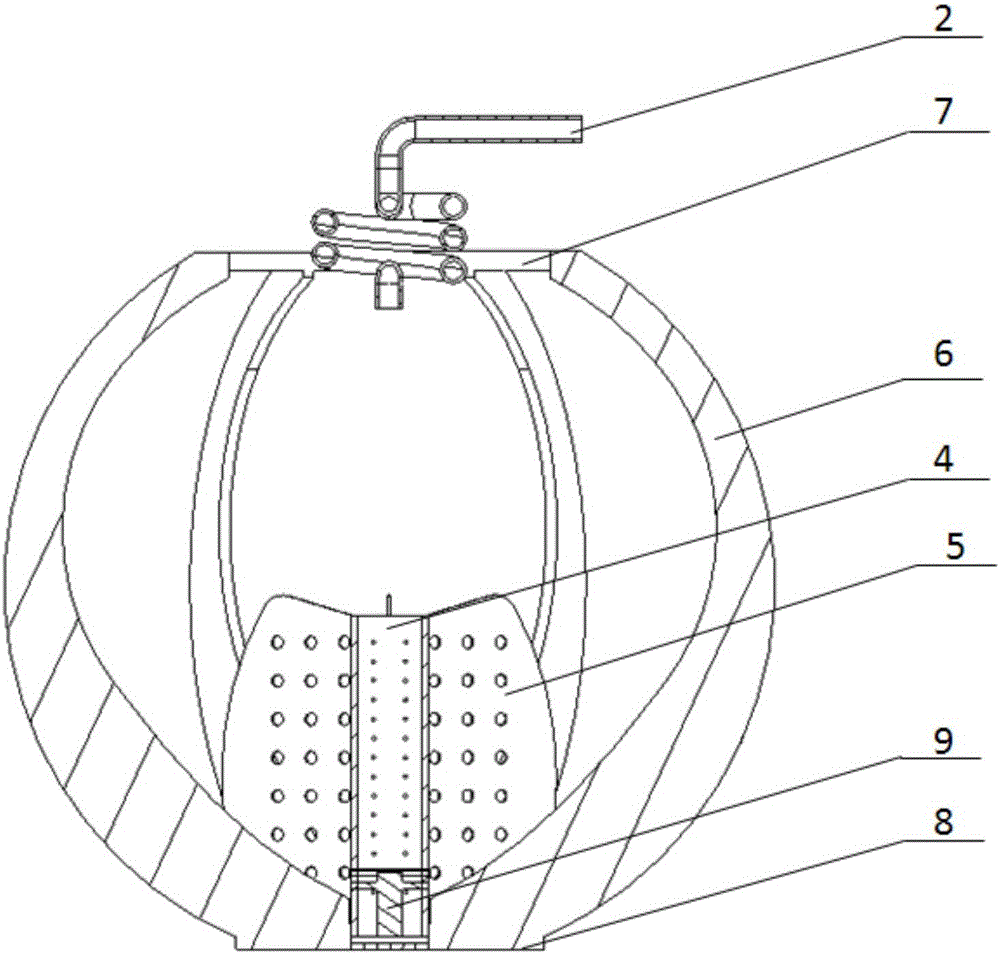

[0028] like Figure 1-4Shown is a schematic diagram of the gas-liquid phase separation management system of the new EHD space fuel tank, the system includes: tank wall 1, exhaust pipe 2, drain / fill port 3, center cylinder 4 (upper cylinder 401, lower cylinder 402) , Inner deflector 5, outer deflector 6, upper tray ring 7, lower tray 8, positive electrode rod 9.

[0029] The central cylinder 4 of the space plate type surface tension fuel storage tank is composed of an upper cylinder 401 and a lower cylinder 402, and a plurality of mm-scale small holes are opened on the circumferential walls of the upper cylinder 401 and the lower cylinder 402, and the upper cylinder 401 and the lower cylinder 402 are inserted into Connected or welded inner deflector 5 realizes upper and lower fixed connections. The interface between the upper cylinder 401 and the lower cylinder 402 and the outer peripheral surface of the lower cylinder are sprayed with epoxy resin coating, which is used for ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com