Machine tool oil separation and high-precision filtering equipment for machining center

A technology of oil-liquid separation and processing center, which is applied in the direction of liquid separation, filtration separation, separation methods, etc., and can solve problems such as unrecyclable oil slicks, air pollution, and prolonging the time for cutting fluid to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

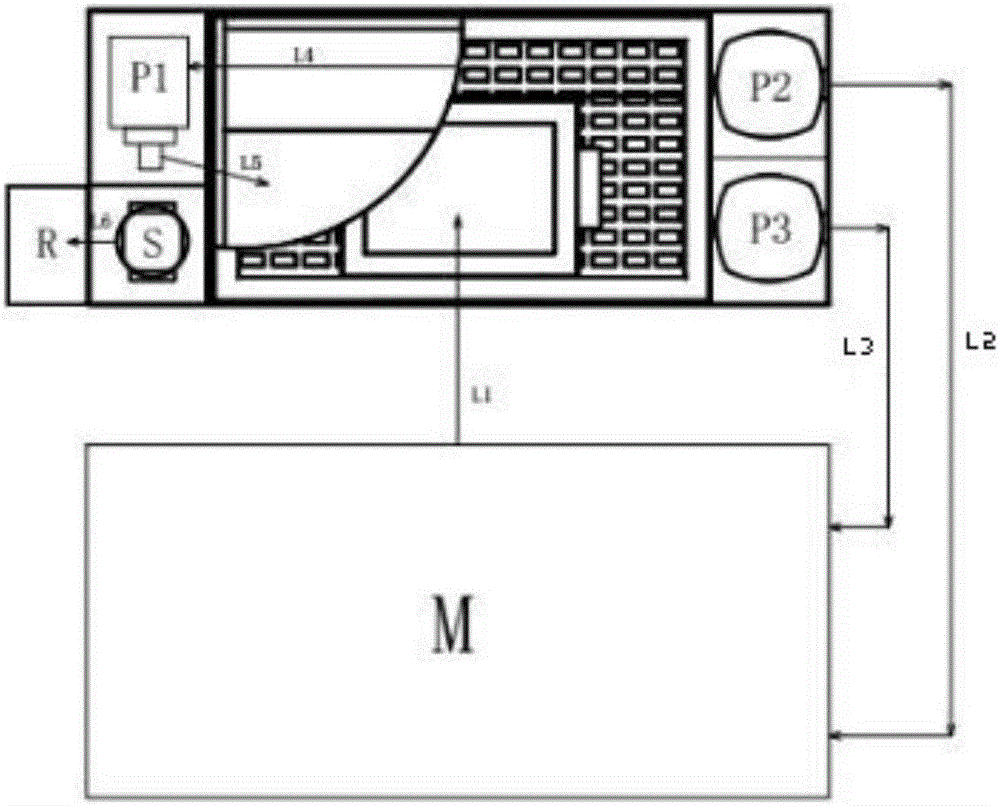

[0026] see Figure 1-2 As shown, the present invention discloses a machine tool oil separation and high-precision filtering equipment for a machining center, including a dirty oil tank M for accommodating the dirty oil of the machine tool, a coarse filter device T6 for preliminary filtering of the dirty oil, and a The fine filter device T7 and the oil slick device for secondary filtration of dirty oil, the dirty oil enters the coarse filter device T6, the fine filter device T7 and the oil slick device for processing in sequence;

[0027] The internal space of the scraping oil slick device is divided into a clean liquid entry area T4 at one end, a slick oil concentration area T1, and a slick oil scraping area T2, and a clean liquid area T3 and an oil slick buffer area T5 at the other end. The essential oil filtered b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com