Magnetization intensity based TP304H boiler pipe material damage degree detection method

A TP304H, magnetization technology, applied in the direction of material magnetic variables, etc., can solve the problem of not considering material damage, etc., to achieve the effect of small demand, small sample size, and simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

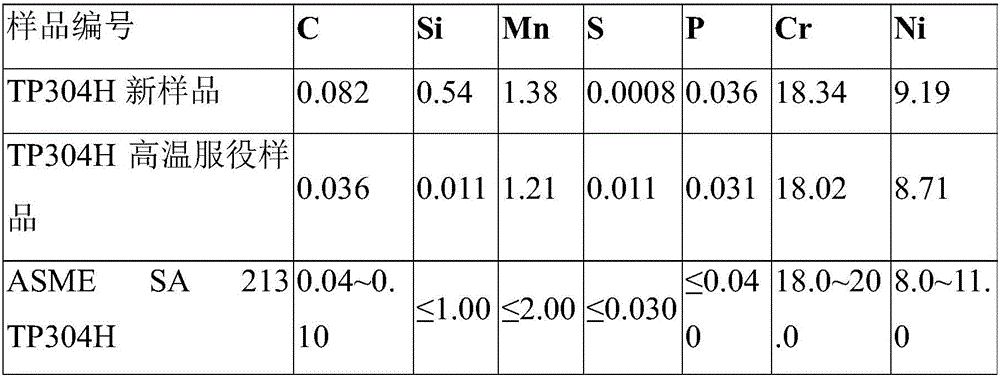

[0021] The materials used in the implementation cases of the present invention are ASME SA213 TP304H boiler tube new samples and high-temperature service samples, and their chemical compositions are shown in Table 1.

[0022] Table 1: Chemical composition (wt%) of TP304H steel in the implementation case

[0023]

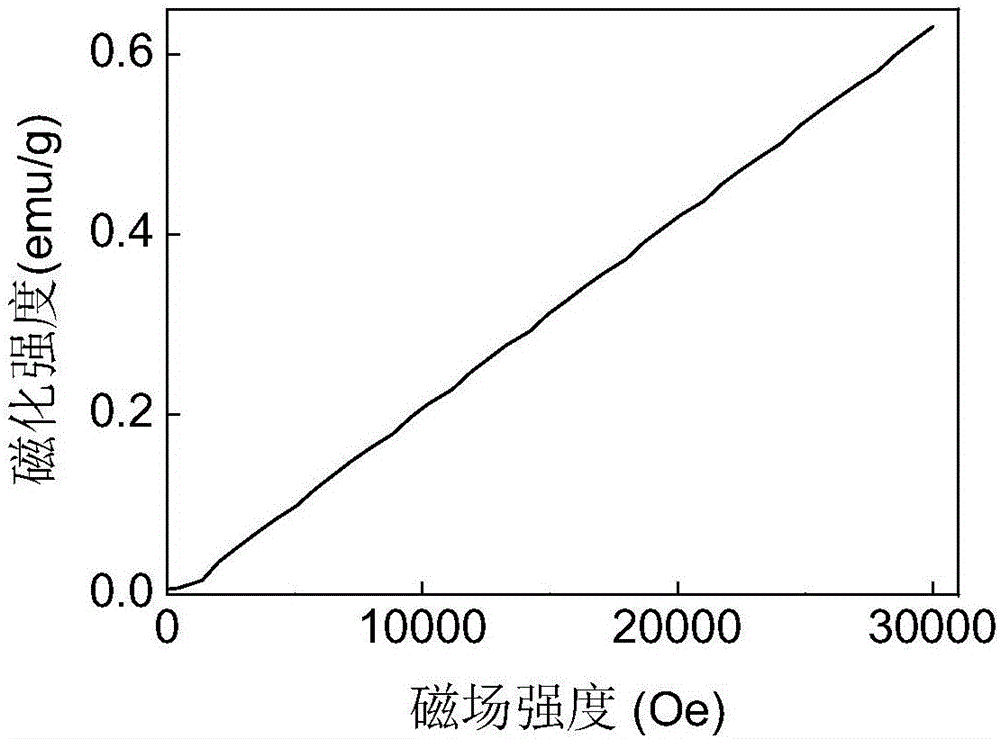

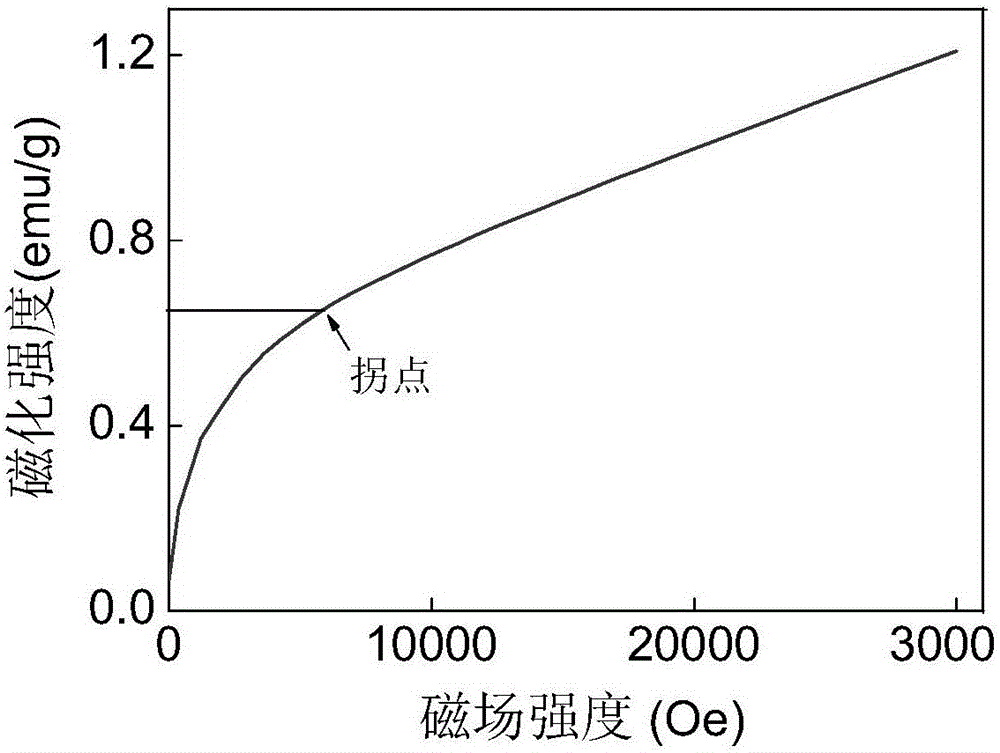

[0024] Firstly, a sample with a diameter of Φ3mm and a length of about 15mm is prepared from the fire surface of the new TP304H sample and the TP304H high-temperature service sample, and the magnetic test is carried out in the VSM vibrating sample magnetometer to obtain the magnetization curve of the sample, see figure 1 with figure 2 . It can be seen from the figure that there is no inflection point on the magnetization curve of the TP304H new sample, and the magnetization intensity corresponding to the inflection point on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com