Piezoelectric ceramic composite material and preparation method thereof

A technology of composite materials and piezoelectric ceramics, applied in the field of materials, can solve problems such as accumulation of damage, easy to cause major accidents, and various performance degradations, and achieve the effect of good receiving performance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

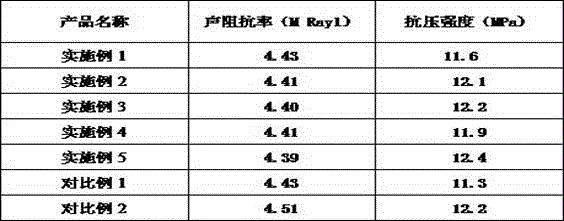

Examples

Embodiment 1

[0022] A piezoelectric ceramic composite material prepared from the following components in parts by weight: 20 parts of Portland cement, 10 parts of aluminate cement, 2 parts of stearic acid amide, 1 part of beeswax, and bisphenol A epoxy resin 5 parts, 5 parts of bisphenol F epoxy resin, 0.2 part of erythritol, 60 parts of piezoelectric ceramic sheet, 2 parts of 651 low molecular weight polyamide, 1 part of m-phenylenediamine, 0.5 part of polyvinyl acetal, 0.1 part of calcium propionate, 0.5 part of sodium carboxymethyl cellulose, 8 parts of absolute ethanol, and 30 parts of water.

[0023] The preparation method of the above-mentioned piezoelectric ceramic composite material is as follows: first mix all the components except the piezoelectric ceramic sheet, stir with a mixer at a speed of 100r / min for 5 minutes, put it into a vacuum system for evacuation for 5 minutes, and eliminate the gas , then put the piezoelectric ceramic sheet into the mold, pour the above mixture int...

Embodiment 2

[0025] A piezoelectric ceramic composite material prepared from the following components in parts by weight: 30 parts of Portland cement, 20 parts of aluminate cement, 3.5 parts of stearic acid amide, 1.5 parts of beeswax, bisphenol A epoxy resin 7.5 parts, 7.5 parts of bisphenol F epoxy resin, 0.35 parts of erythritol, 70 parts of piezoelectric ceramic sheet, 3 parts of 651 low molecular polyamide, 2 parts of m-phenylenediamine, 0.75 parts of polyvinyl acetal, 0.2 parts of calcium propionate, 0.75 parts of sodium carboxymethylcellulose, 9 parts of absolute ethanol, and 40 parts of water.

[0026] The preparation method of the above-mentioned piezoelectric ceramic composite material is as follows: first mix all components except the piezoelectric ceramic sheet, stir with a mixer at a speed of 200r / min for 7.5 minutes, put it into a vacuum system for 7.5 minutes, and eliminate the gas , and then put the piezoelectric ceramic sheet into the mold, pour the above mixture into the ...

Embodiment 3

[0028] A piezoelectric ceramic composite material prepared from the following components in parts by weight: 40 parts of Portland cement, 30 parts of aluminate cement, 5 parts of stearic acid amide, 2 parts of beeswax, bisphenol A epoxy resin 10 parts, 10 parts of bisphenol F epoxy resin, 0.5 parts of erythritol, 80 parts of piezoelectric ceramic sheet, 4 parts of 651 low molecular weight polyamide, 3 parts of m-phenylenediamine, 1 part of polyvinyl acetal, 0.3 parts of calcium propionate, 0.8 parts of sodium carboxymethylcellulose, 10 parts of absolute ethanol, and 50 parts of water.

[0029] The preparation method of the above-mentioned piezoelectric ceramic composite material is as follows: first mix all components except the piezoelectric ceramic sheet, stir with a mixer at a speed of 300r / min for 10 minutes, put it into a vacuum system for 10 minutes to remove gas , and then put the piezoelectric ceramic sheet into the mold, pour the above mixture into the mold and vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com