Wheat bran rice cake and preparation method thereof

A technology of cake dough and bran, which is applied in the field of bran cake dough and its preparation, can solve problems such as non-smoothness, spots on the surface, and rough taste, and is suitable for large-scale industrial production, increasing dispersibility and stability, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

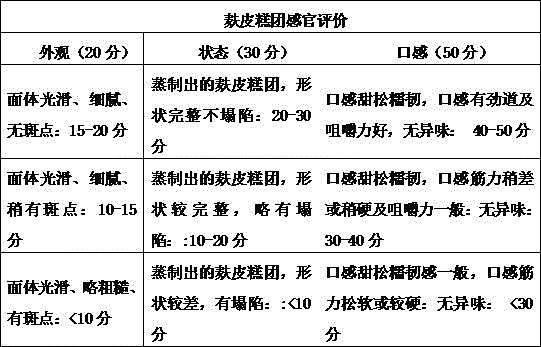

Image

Examples

Embodiment 1

[0035] A bran cake dough, made of the following raw materials in parts by weight: 10-15 parts of wheat bran micropowder, 85-90 parts of glutinous rice flour, 10-20 parts of white sugar, 1.6-2.0 parts of emulsification enhancer, 60- 70 parts of water; the particle size of the wheat bran micropowder is ≤50 μm; the emulsification enhancer is compounded with sucrose fatty acid ester, carrageenan and potassium chloride with an HLB value of 10-16, and the sucrose fatty acid ester: Carrageenan: the ratio of parts by weight of potassium chloride is: 2.0-2.4: 1.0-1.2: 1.0-1.2.

[0036] Above-mentioned bran cake group, its preparation method comprises the following steps:

[0037] (1) Place the wheat bran in a hot air dryer, control the temperature of the hot air at 60-70°C, and dry until the moisture content of the wheat bran is 4.2%; the dried wheat bran is ultrafinely pulverized by an ultrafine pulverizer, ultrafine The sieve of the micro pulverizer is 300 mesh sieve, and the wheat ...

Embodiment 2

[0044] Bran dough, its preparation method comprises the following steps:

[0045] (1) Place the wheat bran in a hot air dryer, control the temperature of the hot air at 60-70°C, and dry until the moisture content of the wheat bran is 4.7%; the dried wheat bran is ultrafinely pulverized with an ultrafine pulverizer, A 300-mesh sieve is selected as the sieve of the superfine pulverizer, and after pulverization, wheat bran micropowder is obtained, and its particle size is ≤50 μm;

[0046] (2) Weigh 2.2 kg of sucrose fatty acid ester with an HLB value of 14, 1 kg of carrageenan and 1 kg of potassium chloride on an electronic scale and mix to obtain an emulsification enhancer;

[0047] (3) Weigh 1.5kg of white granulated sugar and 0.18kg of emulsification enhancer on an electronic scale, dry mix for 3-5 minutes, and mix well;

[0048] (4) Add the above mixture to 6.5kg of water while stirring, add 1.2kg of wheat bran micropowder, stir for 3min under the stirring condition of a rot...

Embodiment 3

[0052] Bran dough, its preparation method comprises the following steps:

[0053] (1) Place the wheat bran in a hot air dryer, control the temperature of the hot air at 60-70°C, and dry until the moisture content of the wheat bran is 4.5%; the dried wheat bran is ultrafinely pulverized with an ultrafine pulverizer, A 300-mesh sieve is selected as the sieve of the superfine pulverizer, and after pulverization, wheat bran micropowder is obtained, and its particle size is ≤50 μm;

[0054] (2) Weigh 2.0kg of sucrose fatty acid ester with an HLB value of 16, 1.2kg of carrageenan and 1.2kg of potassium chloride on an electronic scale and mix to obtain an emulsification enhancer;

[0055] (3) Weigh 1.5kg of sugar and 0.2kg of emulsification enhancer on an electronic scale, dry mix for 3-5 minutes, and mix well;

[0056] (4) Add the above mixture to 14kg of water while stirring, add 1.5kg of wheat bran micropowder, stir for 4min under the stirring condition of a rotating speed of 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com