Lithium-sulfur battery composite anode material and preparation method and application thereof

A composite positive electrode material and a technology for positive electrode materials, applied in lithium-sulfur battery composite positive electrode materials and its preparation, and in the application field of lithium-sulfur batteries, can solve the problems of complex preparation process, difficult scale-up production, high cost of raw materials, etc., and achieve preparation The process is simple, the preparation process is easy to scale up, and the effect of high cycle capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment prepares lithium-sulfur battery composite cathode material according to the following steps:

[0029] (1) Put 1 g of sodium alginate and 15 mg of Ketjen black (KB) into a ball mill jar, then add 1 mL of deionized water, and use a ball mill to mill for 2 hours (the speed of the ball mill is 1000 rpm), take it out, and dry to obtain the precursor;

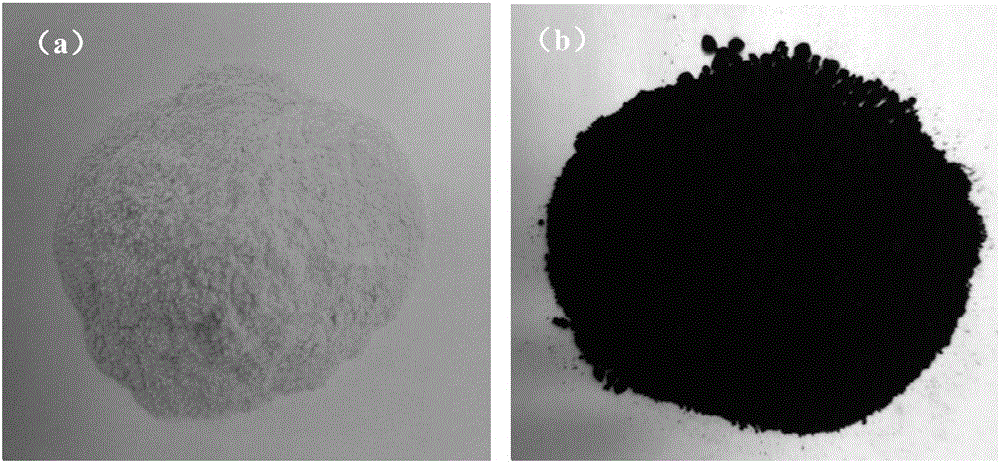

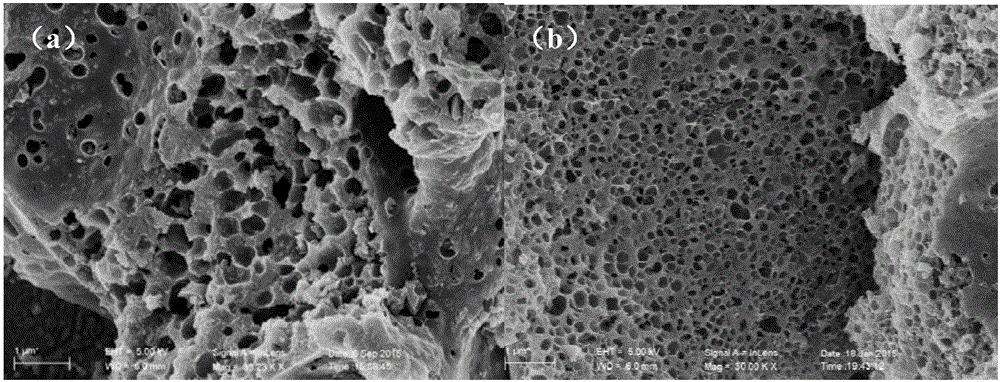

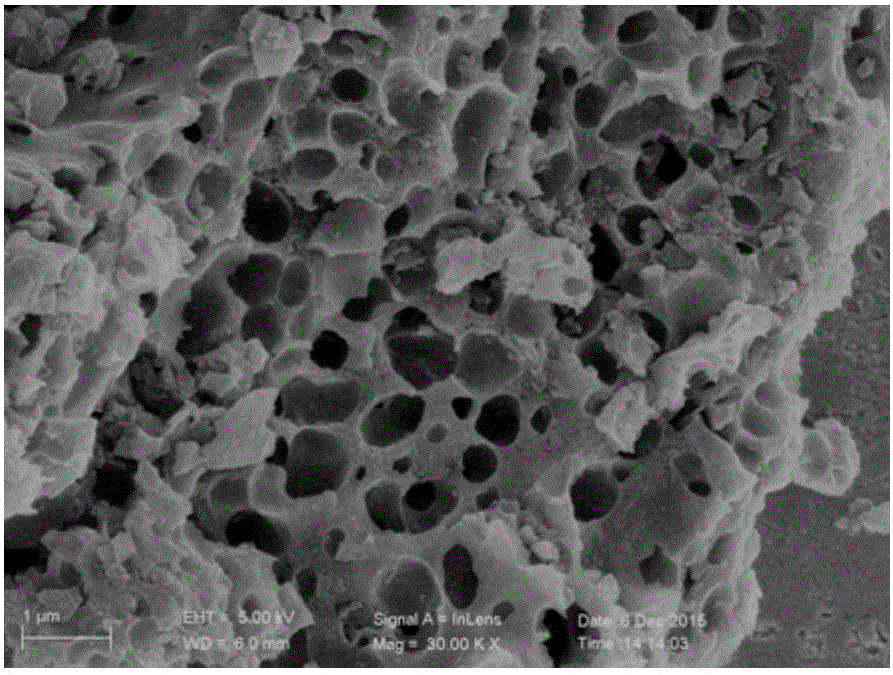

[0030] (2) Place the precursor in an argon atmosphere, raise the temperature to 800°C, and then heat-preserve and anneal for 2 hours to carbonize the sodium alginate. After cooling to room temperature naturally, take it out, and it will be the conductive network-embedded hierarchical porous carbon carrier KBHPC;

[0031] (3) Put KBHPC and elemental sulfur in a ball mill with a mass ratio of 4:1 and mill them evenly; then raise the temperature to 155°C in an argon atmosphere and keep it warm for 12 hours, and take it out after the temperature drops to room temperature to obtain a lithium-sulfur battery Composite...

Embodiment 2

[0039] This embodiment prepares lithium-sulfur battery composite cathode material according to the following steps:

[0040](1) Put 1 g of sodium alginate and 10 mg of carbon nanotubes (CNTs) in a ball mill jar, then add 2 mL of deionized water, use a ball mill to mill for 3 hours (the speed of the ball mill is 1000 rpm), take it out, and dry it to obtain a precursor;

[0041] (2) Put the precursor in an argon atmosphere, raise the temperature to 800°C, and then heat-preserve and anneal for 2 hours to carbonize the sodium alginate, and take it out after cooling down to room temperature naturally, which is the conductive network-embedded hierarchical porous carbon carrier CNTHPC;

[0042] (3) Put CNTHPC and elemental sulfur in a ball milling tank at a mass ratio of 1:1 and mill them evenly; then raise the temperature to 180°C for 20 hours in an argon atmosphere, and take it out after the temperature drops to room temperature to obtain a lithium-sulfur battery composite Cathode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com