Monocrystalline silicon double-sided solar cell and preparation method thereof

A technology of double-sided solar cells and monocrystalline silicon, which is applied in the field of solar cells to achieve the effects of improving quantum conversion efficiency, simple process, and reducing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

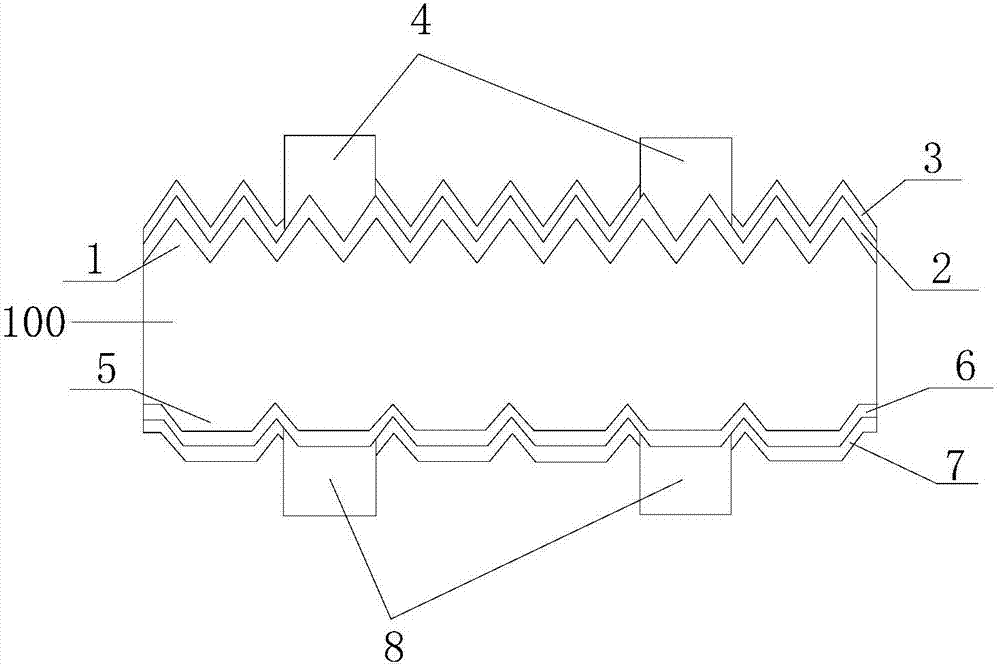

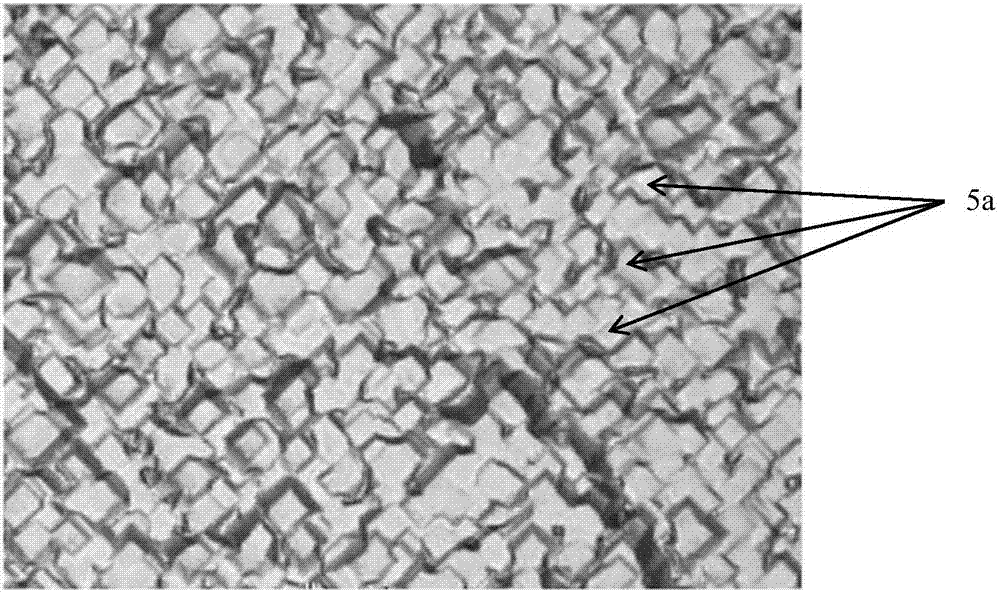

[0029] This embodiment is the case where the present invention is applied to P-type single crystal silicon. Such as figure 1 As shown, on the front side of the P-type single crystal silicon substrate 100, a front textured topographic structure 1 is sequentially formed, in this embodiment, it is a front pyramid-shaped textured surface, a front phosphorus-doped emitter junction 2, and a front passivation anti-reflection medium. layer 3 and the front electrode 4, on the back of the P-type single crystal silicon substrate, the back texturing topography structure 5, the boron-doped back surface field 6 formed by boron doping on the back, the back passivation anti-reflection dielectric layer 7 and back electrode 8, where, as figure 2 As shown, the back surface texture structure 5 is a platform-shaped suede surface, and each platform structure 5a is scattered, or partially connected, or partially overlapped, or distributed on the silicon substrate in a partially dispersed, partiall...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 lies in that in the textured topography structure 5 on the back, each platform structure 5 a is distributed on the silicon substrate in a partially dispersed and partially connected manner. The side length of the plane on the platform structure 5 a is 10 μm, and the height of the platform structure 5 a is 8 μm. The front passivation anti-reflection medium layer 3 is a single-layer film made of silicon oxynitride with a film thickness of 70 to 80 nm; the back passivation anti-reflection medium layer 7 is a double-layer film made of titanium oxide and silicon oxide, wherein, The titanium oxide film has a thickness of 20 to 30 nm and the silicon oxide film has a thickness of 50 to 70 nm. Both the front electrode 4 and the back electrode 8 are copper electrodes.

Embodiment 3

[0034] This embodiment is a case where the present invention is applied to N-type single crystal silicon. Such as figure 1 As shown, on the front side of the N-type single crystal silicon substrate 100, a front pyramid-shaped textured surface 1, a front boron-doped emitter junction 2, a front passivation anti-reflection dielectric layer 3, and a front electrode 4 are sequentially formed. The back surface of the silicon substrate is sequentially formed with a back textured topographic structure 5, a phosphorus-doped back surface field 6 formed by phosphor doping on the back, a back passivation anti-reflection dielectric layer 7, and a back electrode 8, wherein the back textured topographic structure 5 is a platform-shaped suede surface, and each platform structure 5a is dispersedly distributed on the silicon substrate. Such as figure 1 As shown, the platform structure 5a has a lower plane connected to the silicon substrate 100 and an upper plane opposite to the lower plane. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com