Wall surface putty adsorbing formaldehyde and continuously releasing anions and preparation method thereof

A technology of continuous release and adsorption of formaldehyde, applied in the direction of filling slurry, etc., can solve problems such as human harm, and achieve the effect of strong covering power, smooth hand feeling and soft surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

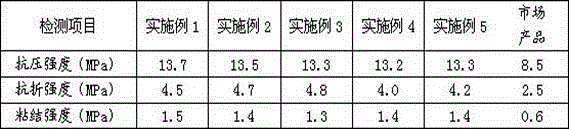

Examples

preparation example Construction

[0037] A preparation method for wall putty that absorbs formaldehyde and continuously releases negative ions, comprising the following steps:

[0038] a. Mechanically pulverize the bagasse and pass through a 120-mesh sieve, put it into deionized water, heat to 48°C, add citric acid and keep it for 8 hours;

[0039] b. Take out the bagasse and put it into 12% salt water, soak for 28 minutes;

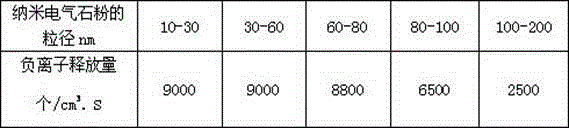

[0040] c. Take out the bagasse, put it into the mixed solution of nano-titanium dioxide and nano-tourmaline powder, and use ultrasonic treatment for 8min with a frequency of 45kHz;

[0041] d, after bagasse is taken out, dry;

[0042]e. Pour barite powder, hexacyclic stone powder, nano-tourmaline powder, and nano-titanium dioxide into the mixer in turn, mix and stir, and stir for 12 minutes;

[0043] f. Pour glutinous rice glue powder and natural calcium powder into the blender and stir for 11 minutes;

[0044] g. Pour the bagasse into the blender and stir for 18 minutes;

[0045] h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com