Inorganic thermal insulation mortar toughened by doping wheat straw fibers and application method thereof

A technology of inorganic thermal insulation mortar and wheat straw, which is applied in the field of building materials, can solve the problems of vitrified microbeads that are easily damaged and broken, reduced thermal insulation performance, shrinkage cracking, etc., and achieves reduced drying shrinkage performance, improved construction performance, and high early strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: An inorganic thermal insulation mortar mixed with wheat straw fiber toughening, according to Portland cement 100, calcium hydroxide 25, high calcium fly ash 25, aluminate cement 30, vitrified microbeads 65, short Cut wheat straw 25, wheat straw fiber 3, polyacrylonitrile fiber 0.5, styrene-butadiene emulsion 12, sodium lauryl sulfate air-entraining agent 0.2, hydroxypropyl starch ether 2, water 115 weight ratio prepared. Add materials according to the above-mentioned sequence and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 2

[0054] Example 2: An inorganic thermal insulation mortar mixed with wheat straw fiber toughening, according to Portland cement 100, calcium hydroxide 35, high calcium fly ash 20, aluminate cement 40, vitrified microbeads 50, short Cut wheat straw 15, wheat straw fiber 2.5, polyacrylonitrile fiber 0.9, styrene-butadiene emulsion 8, sodium lauryl sulfate air-entraining agent 0.15, hydroxypropyl starch ether 3, water 125 weight ratio prepared. Add materials according to the above-mentioned sequence and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

Embodiment 3

[0055] Example 3: An inorganic thermal insulation mortar mixed with wheat straw fiber toughening, according to Portland cement 100, calcium hydroxide 45, high-calcium fly ash 45, aluminate cement 40, vitrified microbeads 40, short Cut wheat straw 10, wheat straw fiber 4, polyacrylonitrile fiber 0.7, styrene-butadiene emulsion 16, sodium lauryl sulfate air-entraining agent 0.35, hydroxypropyl starch ether 3.5, water 150 weight ratio prepared. Add materials according to the above-mentioned sequence and stir evenly to obtain the desired product. The performance test results are shown in Table 1.

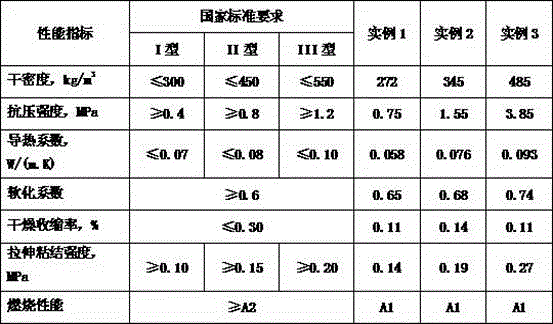

[0056] Table 1 embodiment performance test result

[0057]

[0058] It can be seen from the above examples that the inorganic thermal insulation mortar mixed with wheat straw fiber toughening proposed by the present invention can be formulated with flame-retardant thermal insulation mortar with different thermal insulation effects according to requirements, and all performance indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com