Industrial Microwave Heating Apparatus Using Helical Antenna Radial Power Radiation

A technology of microwave heating device and helical antenna, which is applied in microwave heating, electric heating device, electric/magnetic/electromagnetic heating and other directions, can solve the problems of complicated structure, poor uniformity and poor heating efficiency of microwave oven, and achieves simple structure and low production cost. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

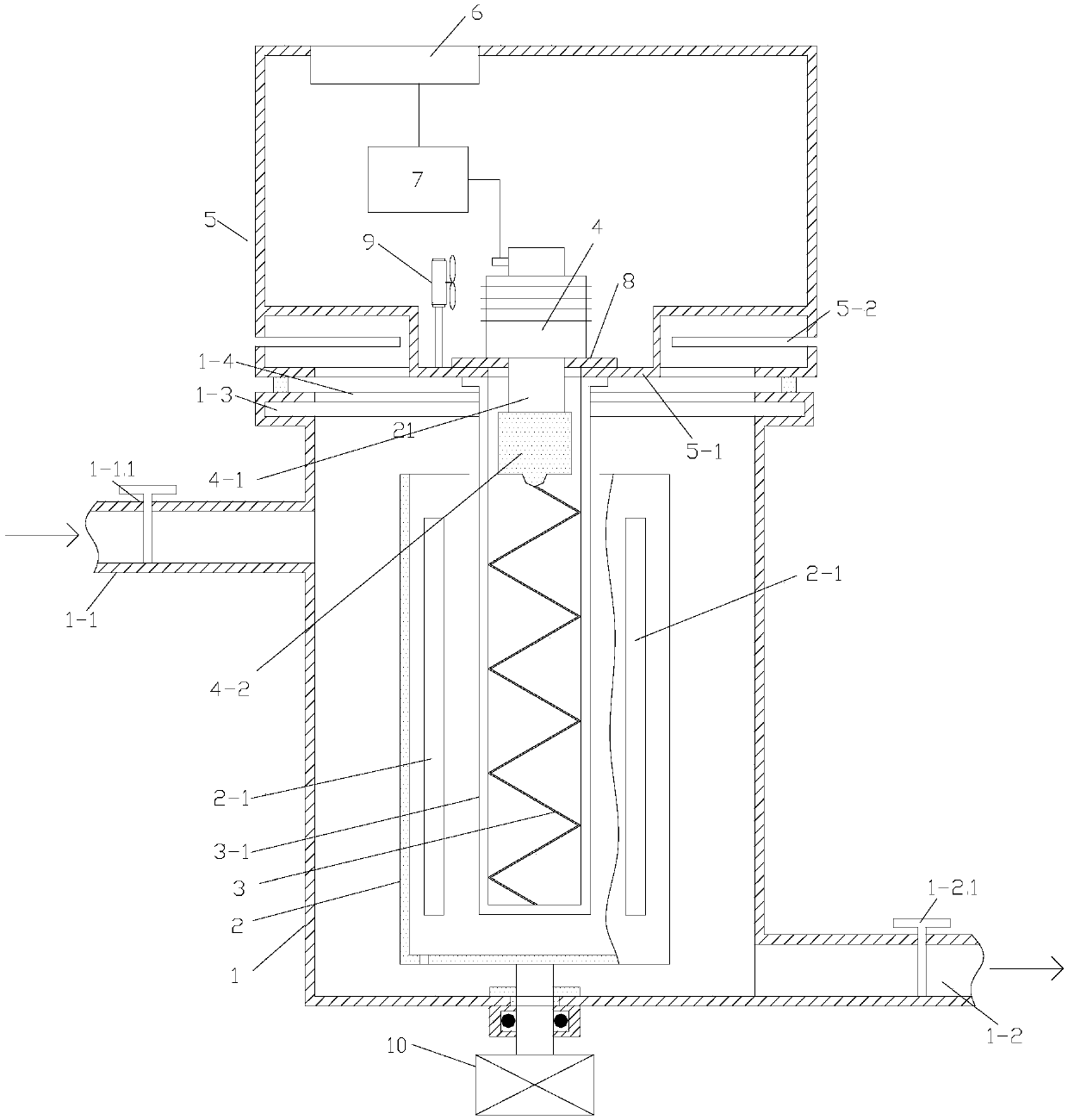

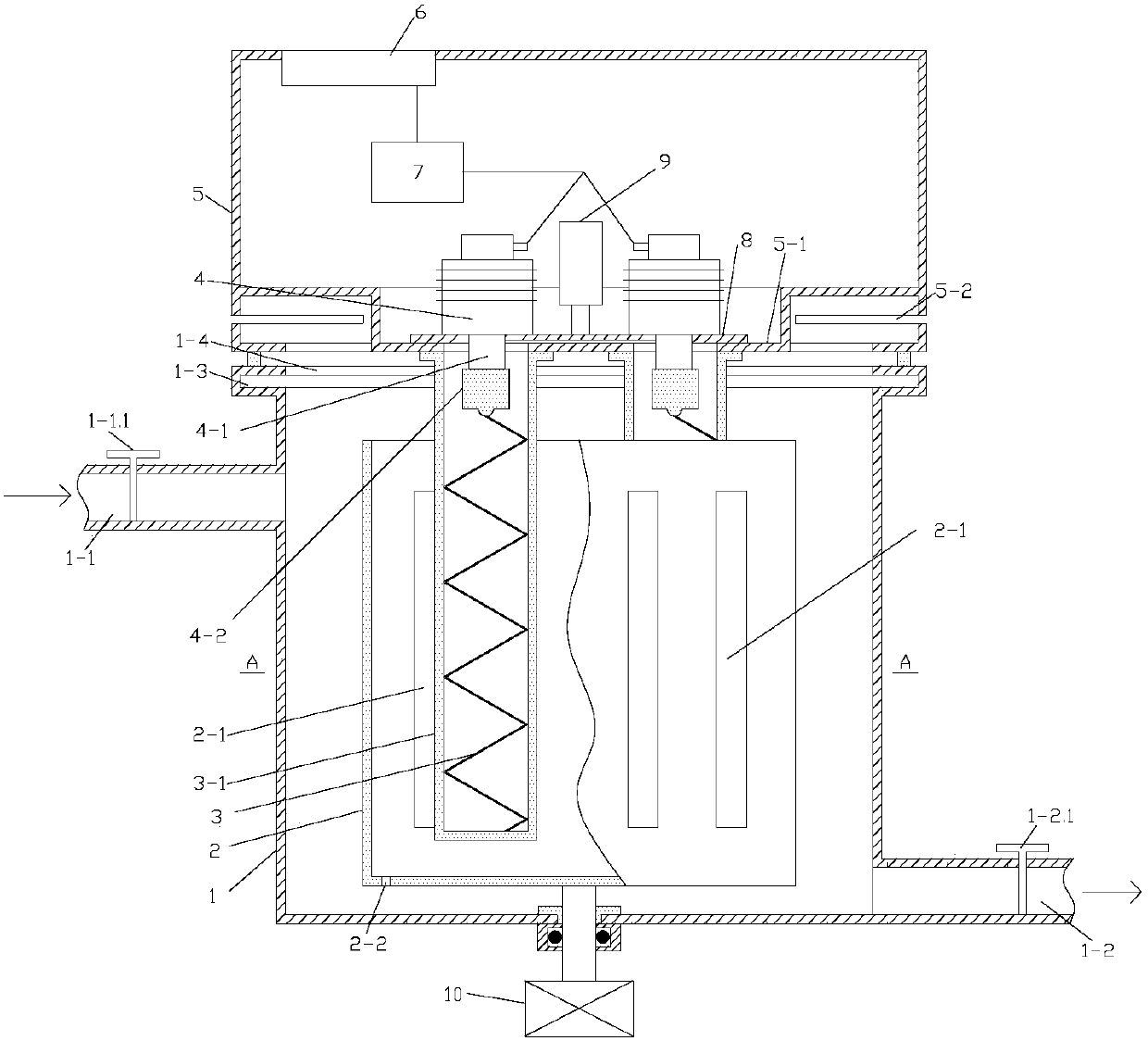

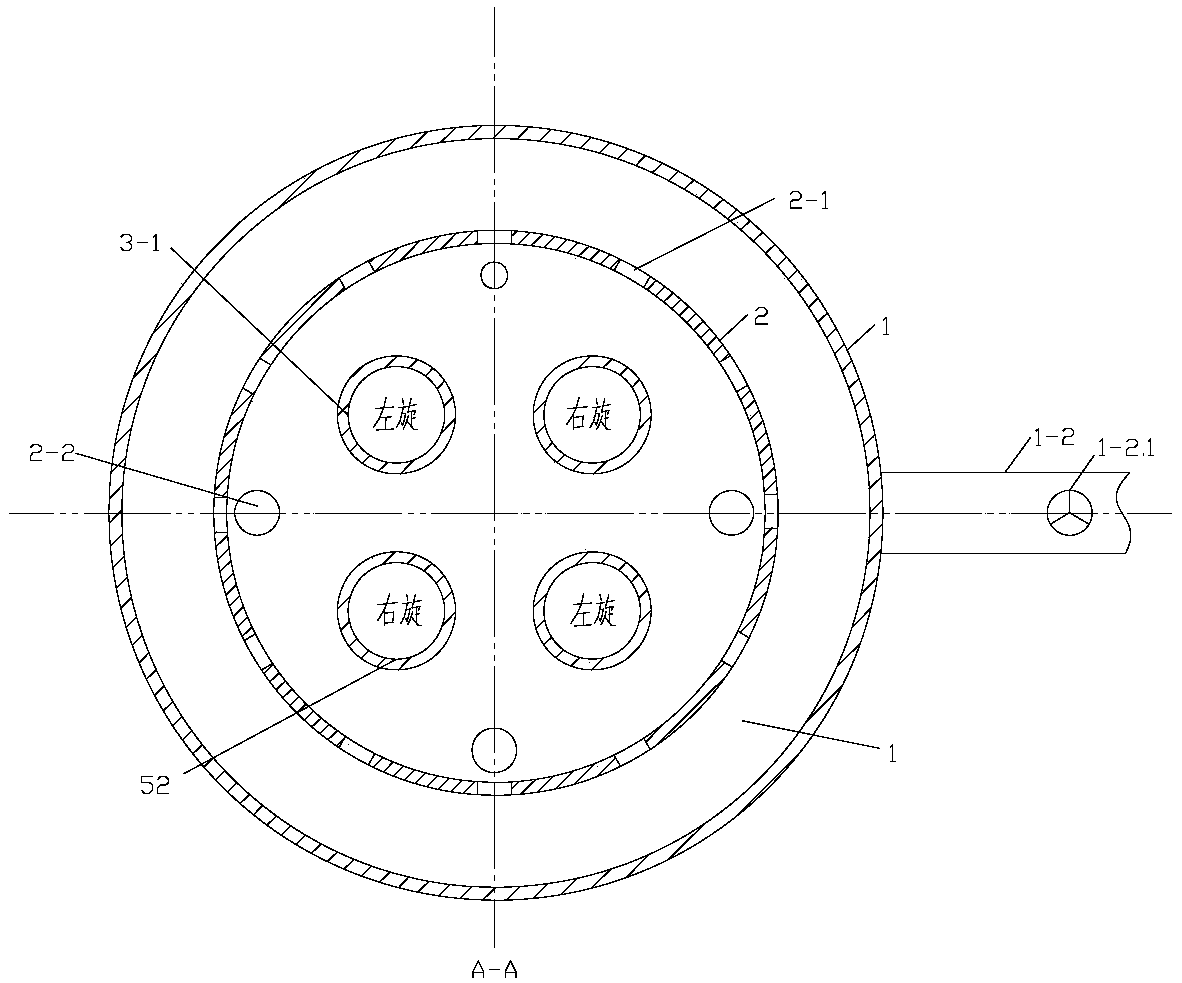

[0011] Embodiment 1: take output power 1300W (rated input power 1500W), the working frequency f=2450MHz of microwave source, the heating device that barrel 1 volume is 35L (liter) as example: barrel 1 inner diameter Φ 300mm, height (including reflux Groove 1-3) 530mm, wall thickness 1.5mm, large inner diameter of circular anti-flow groove 1-3 is Φ360mm, axial height is 30mm, inner diameter of barrel top 1-4 is also Φ300mm, inlet and outlet: 1 -1, 1-2 inner diameters are Φ15mm, the material of the whole barrel 1 is stainless steel; mixing drum 2 inner diameter Φ150mm, height 400mm, the material is engineering plastics, the (material liquid) circulation tank 2-1 (height× Width) 350×15mm, set 8 at equal intervals on the cylinder wall, and set 4 at equal intervals at the bottom of material cylinder 1, the residual material discharge holes 2-2 have a diameter of Φ15mm; the wire diameter (minor diameter) of the spiral antenna 3 is Φ3mm, and the large diameter is Φ25mm , screw pitch ...

Embodiment 2

[0012] Embodiment 2: take output power 4 * 1300W, the operating frequency f=2450MHz of microwave source, the heating device that barrel 1 volume is 100L (liter) as example: barrel 1 internal diameter Φ 500mm, high (including anti-flow tank 1-3 )530mm, wall thickness 2.0mm, large inner diameter Φ560mm, axial height 30mm of annular anti-flow tank 1-3, inner diameter of upper opening 1-4 of barrel is also Φ500mm, inlet and outlet 1-1, 1- The inner diameter of 2 is Φ20mm, and the material of the whole barrel 1 is stainless steel; the inner diameter of mixing drum 2 is Φ440mm, the height is 400mm, and the material is engineering plastics. 16 are arranged at equal intervals on the cylinder wall, and the residual material discharge holes 2-2 at the bottom of the barrel 1 have a diameter of Φ15mm and 8 are arranged at equal intervals; the magnetron 4 of this embodiment adopts four magnetrons and the supporting Four sets of microwave power radiation assemblies, the model and operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com