Carbon-based composite positive electrode material for lithium-air battery and preparation method thereof

A composite positive electrode material and carbon material technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to prepare a catalytic positive electrode material system for lithium air, achieve multiple catalytic reaction active sites, reduce agglomeration, reduce The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a carbon-based composite cathode material for a lithium-air battery, comprising the following steps:

[0045] (1) Add a certain amount of carbon material into ethylene glycol, mix, sonicate, and prepare a suspension containing carbon material;

[0046] (2) Slowly add a certain amount of ionic liquid into the above suspension, accompanied by magnetic stirring during the whole process, so that the solution is fully and evenly mixed;

[0047] (3) Add a certain amount of hydrochloric acid solution of the noble metal precursor to the above-mentioned uniformly mixed solution, place it in an oil bath at 150-220° C. for 3-5 hours in a condensing reflux device, then cool, centrifuge, filter, and dry, That is, the desired carbon-based composite cathode material for the lithium-air battery is obtained.

[0048] The step (1) is: weigh a certain amount of carbon material, dissolve it in ethylene glycol, ultrasonicate for 3-5 minutes, st...

Embodiment 1

[0070] 1) Preparation of nanoscale Ru-imidazole-type ionic liquid-multi-walled carbon nanotube composite cathode material:

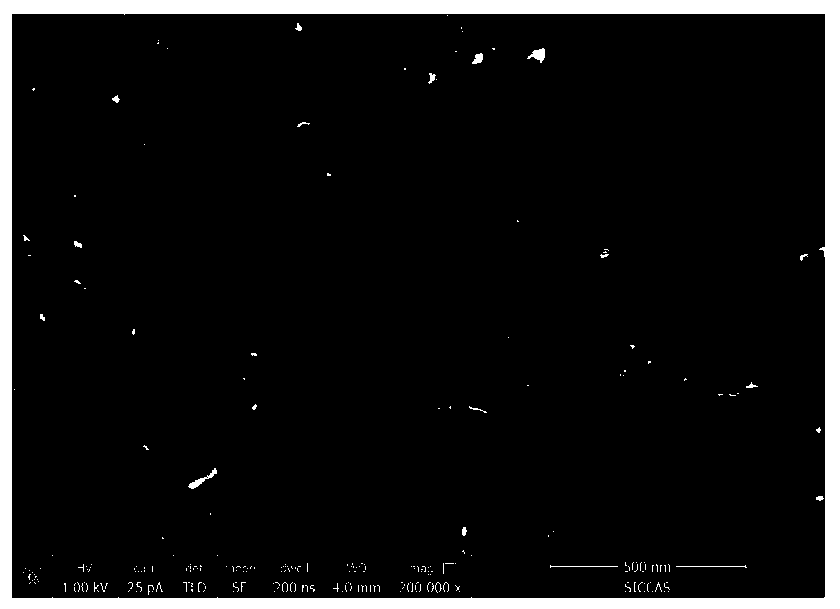

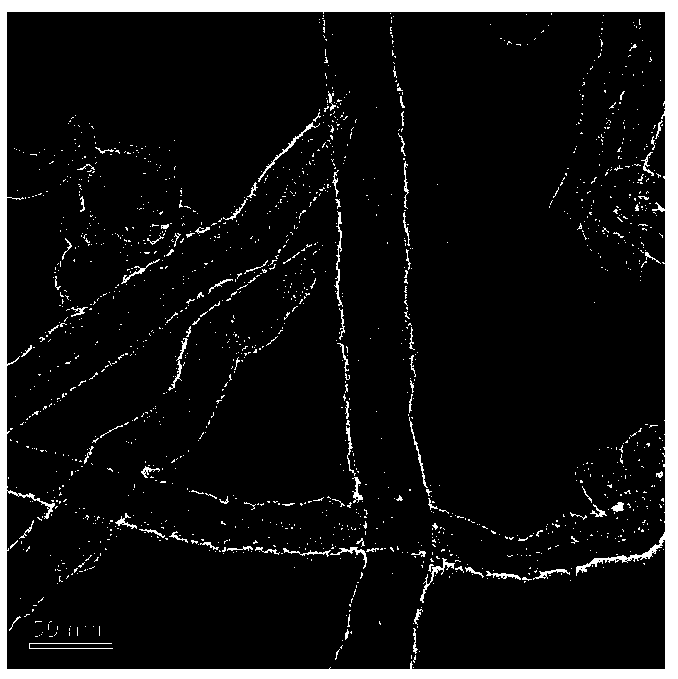

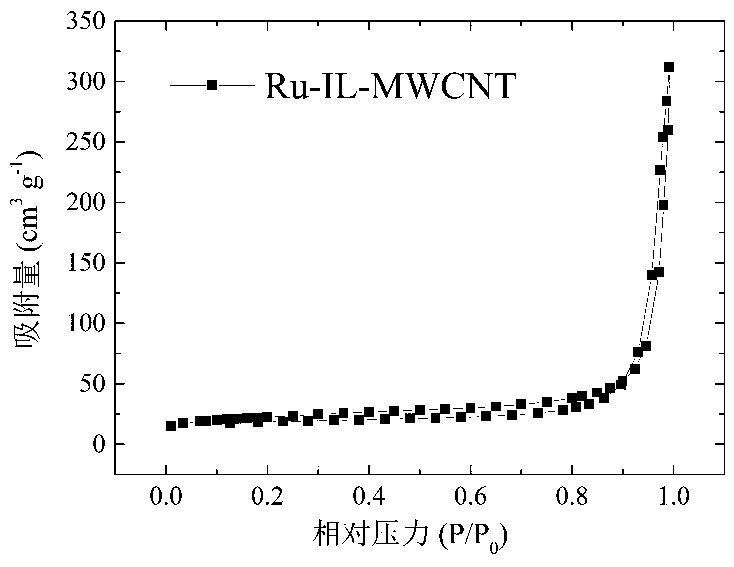

[0071] Weighing 30 mg of multi-walled carbon nanotubes was added to 60 mL of ethylene glycol, ultrasonicated for 5 minutes, and stirred for 3 hours to obtain a suspension of multi-walled carbon nanotubes. Then, while stirring, slowly drop 1100uL 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIm]BF 4 ) ionic liquid, ultrasonicated for 5 minutes, and continuously stirred for 4 hours to obtain a fully mixed solution. Then add 22.5 mg RuCl to the solution 3 The mixed solution in 1.5mL of 0.1mol / L hydrochloric acid was placed in an oil bath at 190°C. After 3 hours, the temperature was naturally cooled, and the reaction precipitate was repeatedly washed by centrifugation with ethanol and deionized water, and the described product was obtained after air drying at room temperature. composite material. The SEM and TEM of Ru-ionic liquid-multi-walled carbon ...

Embodiment 2

[0075] 1) Preparation of nanoscale Pd-imidazole type ionic liquid-graphene composite cathode material:

[0076] Weigh 25 mg of graphene and add it into 60 mL of ethylene glycol, sonicate for 5 minutes, and stir for 3 hours to obtain a suspension of graphene. Then, while stirring, slowly drop 1000uL 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIm]BF 4 ) ionic liquid, ultrasonicated for 5 minutes, and continuously stirred for 4 hours to obtain a fully mixed solution. Then add 39.1mg Pd(C 2 h 3 o 2 ) 2 Dissolve in 1.5mL of 0.1mol / L hydrochloric acid solution, place in an oil bath at 200°C for 3 hours, then cool down naturally, wash the reaction precipitate repeatedly with ethanol and deionized water, and dry it with air at room temperature to obtain Pd- ions Liquid-graphene composite; the specific surface area of the composite is 200m 2 / g, the metal particle size is 5nm, and the thickness of the protective layer is 2nm;

[0077] 2) Electrode preparation, battery as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com